Table of Contents

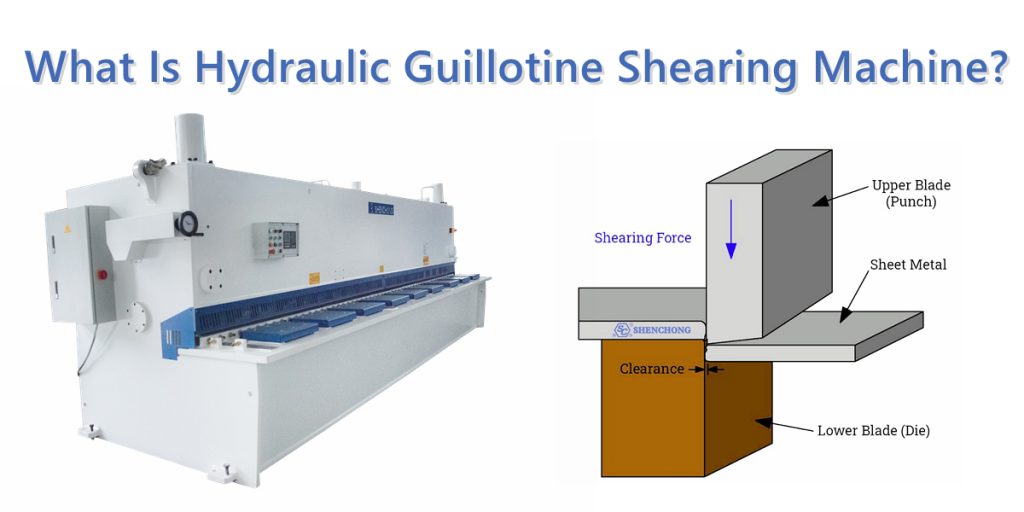

Hydraulic guillotine shearing machine is a kind of metal plate processing equipment that uses hydraulic drive system for shearing operation, mainly used for shearing metal plates of various thicknesses.

Compared with mechanical shearing machine, hydraulic guillotine shearing machine has the advantages of simple structure, strong shearing force, low noise and stable operation, and is suitable for mass cutting of medium and thick plates.

1. What is hydraulic guillotine shearing machine working principle?

The working principle of hydraulic guillotine shearing machine is mainly based on the hydraulic transmission system to push the knife frame up and down to complete the shearing of metal plates.

Working steps:

The whole process can be divided into the following steps.

1) Hydraulic system drive

- Hydraulic pump: The motor drives the hydraulic pump to extract the hydraulic oil from the oil tank and deliver it to the hydraulic cylinder after pressurization.

- Hydraulic cylinder: After the hydraulic oil enters the hydraulic cylinder, it pushes the piston to move, thereby driving the tool holder to move up and down.

- Pressure control: The hydraulic system adjusts the shear force through the pressure valve to ensure that the shearing process is smooth and safe.

2) Tool holder movement and shearing process

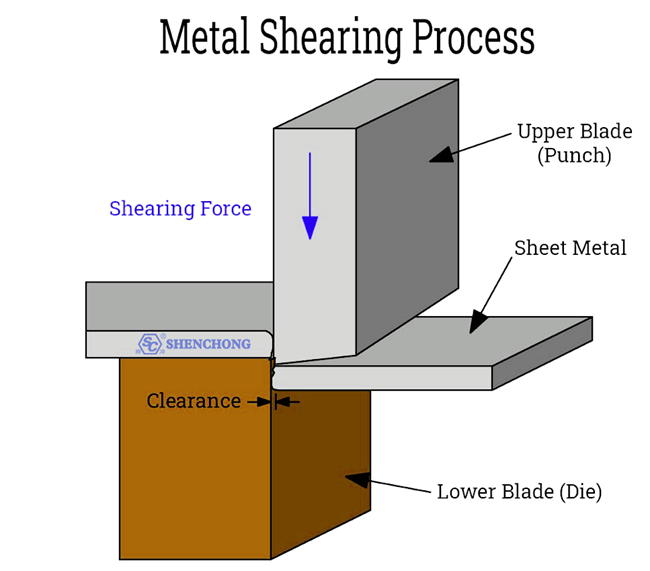

- Upper tool holder presses down in a straight line: The hydraulic cylinder pushes the upper tool holder down in a straight line in the vertical direction, and the blade fixed on the upper tool holder begins to contact the plate.

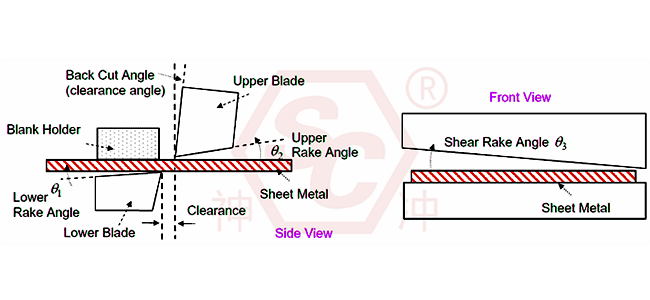

- Shearing action: The upper blade is gradually pressed down, forming a shear force with the lower blade fixed on the workbench to cut the metal plate.

- Shearing gap adjustment: The gap between the upper and lower blades can be adjusted by adjusting the bolt. According to the thickness of the plate, selecting an appropriate gap can ensure the shearing quality and flatness.

3) Back stop device controls the length

- Back stop positioning: The position of the back stop is adjusted by the CNC system or manually to determine the length of the sheared plate.

- Precision control: High-end hydraulic shearing machines are usually equipped with CNC systems. The position of the back gauge can be accurately controlled to ensure the accuracy of the shearing size.

4) Return and reset

- Hydraulic return: After the shearing is completed, the hydraulic system causes the hydraulic cylinder to move in the opposite direction through the reversing valve, and the upper knife holder returns to the initial position.

- Preparing for the next shearing: The back gauge device can be adjusted automatically or manually to prepare for the next shearing operation.

5) Safety and monitoring system

- Overload protection: The hydraulic system is equipped with an overload protection valve to avoid equipment damage due to overload shearing.

- Photoelectric protection device (optional): High-end equipment is usually equipped with a photoelectric protection device to prevent operators from misoperating in the shearing area.

- Pressure and position sensor: Used to monitor the shearing force and knife holder position in real time to ensure the stability and safety of the shearing process.

Workflow summary:

Start the hydraulic pump → the hydraulic cylinder pushes the cutter head down → the upper blade cuts the plate → the hydraulic cylinder returns in the reverse direction → prepares for the next cut.

2. Features of hydraulic guilltine shears

Hydraulic guillotine shearing machines are widely used in sheet metal processing, machinery manufacturing and other industries due to their strong shearing ability and stability.

The following are its main features:

1) Strong shearing force, suitable for thick plates

Adopting a hydraulic drive system, the output shearing force is large, suitable for shearing medium and thick plates (usually up to tens of millimeters thick).

It can effectively deal with materials with high hardness such as high-strength steel and stainless steel.

2) High shearing accuracy and smooth shearing surface

Adopting a reasonable blade gap adjustment design, the shearing surface is smooth and burr-free.

The application of CNC system makes the shearing size more precise and can be controlled within ±0.1mm.

3) Smooth operation and low noise

The smooth drive of the hydraulic system reduces shock and vibration, and the operation process is quiet.

Compared with mechanical shears, it has lower noise and a more comfortable working environment.

4) Anti-overload function, safe and reliable

Equipped with a hydraulic system overflow valve and overload protection device to prevent overload work and damage to the equipment.

Some high-end models are equipped with photoelectric protection devices to prevent misoperation.

5) Easy maintenance and long life

The hydraulic system has good sealing and less wear, which reduces the maintenance frequency.

The blade material is usually high-strength alloy steel, which has strong wear resistance and long service life.

6) Flexible and adjustable shearing angle and stroke

The shearing angle can be adjusted according to the thickness of the plate to reduce shearing deformation.

The tool holder stroke can be adjusted to improve efficiency, especially suitable for continuous shearing of small-sized plates.

7) Intelligent back gauge device

The back gauge is usually equipped with a CNC system for precise positioning and convenient operation.

Supports multi-step programming, and multiple shearing tasks can be completed in one setting.

8) Energy saving and high efficiency

The hydraulic system adopts energy recovery technology to reduce energy consumption.

The shearing speed is fast, the production efficiency is high, and it is suitable for mass production.

The hydraulic guillotine shearing machine has become the mainstream equipment in the sheet metal processing industry due to its strong shearing force, high precision, stable operation, safety and reliability.

3. Application of hydraulic guillotine shear machine

Hydraulic guillotine shear machines are widely used in many industries due to their strong shearing ability, high precision, stability and wide application range. What is hydraulic guillotine shearing machine used for? They are mainly used to shear metal sheets of various thicknesses and materials.

The following are its main application areas and typical cases:

1) Sheet metal processing industry

- Application scenarios: Shearing common metal materials such as steel plates, stainless steel plates, aluminum plates, and making chassis, cabinets, sheet metal shells, etc.

- Advantages: High-precision shearing ensures the dimensional accuracy and flatness of sheet metal parts, suitable for mass production.

- Typical cases: Electrical cabinets, communication equipment shell manufacturing.

2) Machinery manufacturing industry

- Application scenarios: Used to shear parts of machinery and equipment, such as frames, bottom plates and brackets.

- Advantages: Strong shearing force, suitable for thick plate processing, ensuring the size and cutting quality of mechanical parts.

- Typical cases: Shells and support structures of engineering machinery and mining equipment.

3) Shipbuilding industry

- Application scenarios: Shearing medium and thick steel plates for hulls, such as cabin partitions, decks, etc.

- Advantages: It can handle large and heavy plates with high shearing precision to meet the requirements of hull splicing.

- Typical cases: Hull manufacturing of cargo ships, tankers and warships.

4) Aerospace industry

- Application scenarios: Shearing lightweight and high-strength materials such as aluminum alloys and titanium alloys for fuselage skins, wings, etc.

- Advantages: High precision and stability ensure the consistency of parts and meet aviation standards.

- Typical cases: Manufacturing of aircraft skins and internal structures.

5) Automobile manufacturing industry

- Application scenarios: Shearing body panels, chassis components, such as doors and roofs.

- Advantages: Suitable for metal plates of different thicknesses, with high efficiency in conjunction with automated production lines.

- Typical cases: Body manufacturing of trucks, cars and special vehicles.

6) Construction engineering industry

- Application scenarios: Shearing steel plates for construction, such as floor slabs, wall panels, brackets, etc.

- Advantages: Large shearing force, suitable for thick steel plates and high-strength steel, ensuring the safety of building structures.

- Typical cases: Bridge, steel structure building, factory building construction.

7) Home appliance manufacturing industry

- Application scenarios: Shearing thin plates, such as washing machines, refrigerators, microwave ovens and other shell plates.

- Advantages: High efficiency and precision, meeting the requirements of beauty and flatness of home appliance shells.

- Typical cases: Air conditioner and refrigerator shell manufacturing.

8) Decoration and advertising industry

- Application scenarios: Shearing stainless steel, aluminum plates, etc., for billboards and decorative panels.

- Advantages: Smooth cuts without burrs, suitable for exquisite decorative plate production.

- Typical cases: Shopping mall signs, building exterior wall decoration.

Hydraulic guillotine shearing machine can cover almost all industries involving metal plate processing due to its powerful shearing ability, high precision and good stability.

Different models hydraulic guillotine shears for sale:

- Spain Hydraulic Guillotine Shear QC11K-6X3200

- Peru Shearing Machine With Anti-twist Device 13X6000MM

- 13X3500MM Front Feeding Shearing Machine Automatic Cutting Line

- QC11Y 8×4000 Hydraulic Guillotine Shear For Sale

- QC11Y 12x6000MM Hydraulic Guillotine Shear For Sale

- QC11Y 20×3100 Hydraulic Guillotine Shear For Sale

4. Development trend of guillotine hydraulic shearing machine

With the advancement of technology and changes in industrial needs, hydraulic guillotine shearing machines are also developing continuously.

The following are the development trends of guillotine hydraulic shears in the next few years:

1) Intelligence and automation

Popularization of CNC systems:

With the development of CNC technology (CNC), hydraulic guillotine shears will gradually popularize digital control systems to improve operating accuracy and production efficiency. The CNC system can automatically adjust the shearing angle, blade gap and back gauge position, while optimizing the shearing path, reducing manual intervention and improving processing accuracy.

Intelligent operation:

Through the Internet of Things (IoT) technology, the CNC plate shearing machine can be connected to other production equipment to realize data sharing and intelligent production scheduling. Intelligent sensors can monitor the status of equipment in real time, warn of potential failures in advance, and reduce downtime.

2) Energy saving and environmental protection

Energy-saving hydraulic system:

In order to meet the needs of environmental protection and energy saving, hydraulic guillotine shears will increasingly adopt energy-saving hydraulic systems. This includes optimizing parameters such as hydraulic oil flow and pressure, improving system efficiency, and reducing energy consumption.

Energy recovery technology:

Energy recovery devices in hydraulic systems will be widely used in the future, reducing the power consumption of hydraulic pumps, reducing energy consumption, and further reducing production costs.

Environmentally friendly materials and design: Environmentally friendly oil, low noise design, and reduced exhaust emissions will also become the focus of future equipment design.

3) Efficient processing and versatility

High shearing speed and efficient processing:

With the improvement of hydraulic control technology, the shearing speed of hydraulic guillotine shears will be further accelerated, especially when shearing thick plates to improve production efficiency. The new generation of hydraulic systems will adopt a faster response mechanism to shorten the working cycle and improve production efficiency.

Multifunctional integration:

Hydraulic guillotine shears will combine more functions, such as punching, bending, cutting, etc., to achieve multiple functions of one machine, meet different process requirements, and reduce equipment footprint and production costs.

4) Higher precision and quality

Higher precision shearing:

With the development of precision processing technology, hydraulic guillotine shears will adopt more sophisticated control systems and sensors to achieve ultra-high precision shearing, especially for the processing of small sizes and thin plates.

Automatic calibration and adjustment:

The machine will be able to automatically adjust the blade gap and shear angle according to the thickness, hardness and shearing requirements of different materials to ensure the best shearing quality.

5) Shearing capacity of larger and thicker plates

Enhanced shearing force:

In order to meet the needs of large-scale projects and heavy industries, the shearing force of hydraulic guillotine shears will be further enhanced to handle larger and thicker metal plates.

Shearing of high-strength materials:

With the application of new high-strength steel and alloy materials, hydraulic guillotine shears will be optimized to meet the shearing requirements of these materials.

6) More user-friendly operation interface

Touch screen and graphical interface:

The hydraulic guillotine shear will be equipped with a touch screen and a more intuitive graphical operation interface, which is convenient for operators to monitor, adjust and set in real time, improve the convenience and safety of operation.

Remote control and diagnosis:

The hydraulic shear will realize remote control and fault diagnosis. Operators or maintenance personnel can remotely monitor the status of the equipment through the network, perform troubleshooting and maintenance, and reduce downtime.

7) Digitalization and big data analysis

Data collection and analysis:

The hydraulic guillotine shearing machine will be equipped with advanced sensors to collect the working data of the equipment in real time, including shear force, oil temperature, pressure, running speed, etc. Through big data analysis, the production process can be optimized, production efficiency can be improved and failures can be reduced.

Production traceability:

Through digital technology, the use, production data and maintenance records of each device can be recorded to achieve traceability and quality control of the production process.

What is hydraulic guillotine shearing machine development trend? The future development of hydraulic guillotine shearing machines will mainly focus on intelligence, energy saving and environmental protection, high precision, automation and multi-functionality. With the advancement of technology, these trends will not only improve production efficiency and equipment performance, but also make hydraulic shearing machines more adaptable to changing market demands.