Table of Contents

The common non-metallic laser cutting machines in the field include solid laser cutting machines and gas laser cutting machines (CO2 laser cutting machines). Non metallic laser cutting machines generally rely on laser power to drive the laser tube to emit light, which is refracted by several mirrors and transmitted to the laser head. Then, the focusing mirror installed on the laser head converges the light into a point, which can reach a high temperature and instantly sublimate the material into gas, which is sucked away by the exhaust fan to achieve the purpose of cutting. The main gas filled in the laser tube used in general laser cutting machines is CO2, so this type of laser tube is called a CO2 laser tube, and the laser cutting machine that uses this type of laser tube is called a CO2 laser cutting machine.

Carbon dioxide laser is a gas molecular laser, with CO2 gas as the working material and auxiliary gases such as nitrogen, helium, xenon, and hydrogen. Due to the high energy conversion efficiency of this type of laser, it is often used as a high-power output laser. The wavelength of the carbon dioxide laser is 10.6 microns, which is impossible to see infrared light. It has good stability and is widely used.

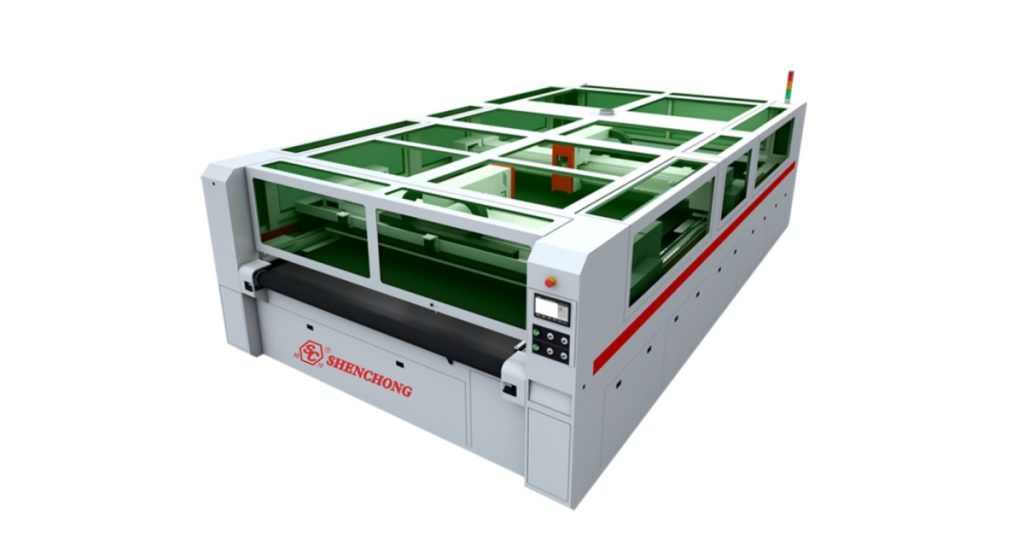

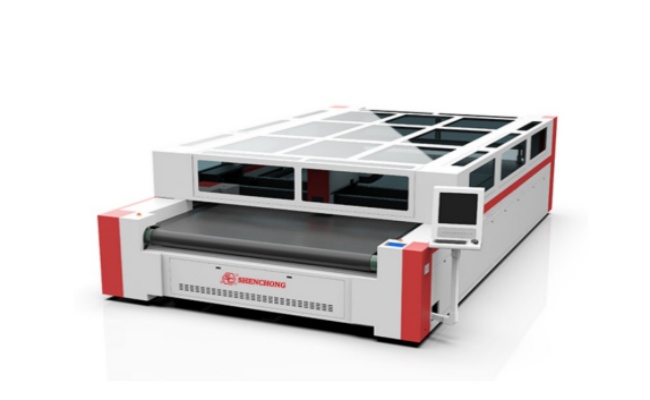

CO2 Laser Cutting Machine Working Principle

The discharge tube of a CO2 laser is filled with a mixture of gases such as CO2, N2, He, etc. The ratio and total pressure can vary within a certain range (usually CO2: N2: He=1:0.5:2.5, with a total pressure of 1066.58pa). Any molecule has three different forms of motion: first, the movement of electrons within the molecule determines the electron energy state; second, the vibration of atoms within the molecule, which is periodic vibration around its equilibrium position. This motion determines the molecular vibrational energy state; third, the rotation of the molecule determines the molecular rotational energy state. CO2 laser uses the transition between the vibrational and rotational energy levels of CO2 molecules to generate laser.

During the operation, the CO2 laser cutting machine controls the CNC mechanical system to move the spot irradiation position through a computer, thereby achieving automatic cutting. This laser cutting machine integrates laser technology, CNC technology, and precision mechanical technology, and is a type of high-tech equipment.

Components Of CO2 Laser Cutting Machine

Laser

The laser of the CO2 laser cutting machine is the core part of the entire system, mainly composed of a laser tube, a mirror, and a laser power supply. Laser tubes are pipes made of glass or ceramic, filled with carbon dioxide gas and other auxiliary gases. Mirrors are mainly divided into output mirrors and reflection mirrors. The output mirror is used to output the laser beam from the laser tube, while the reflection mirror reflects the laser beam back into the laser tube for gain. The laser power supply provides high-voltage power to control the laser tube, enabling it to produce high-quality laser beams.

Optical Path System

The optical path system consists of a reflector, lens, and scanning mirror. The reflector is mainly used to guide the laser beam to the cutting head, the lens is used to adjust the focus size and power density of the laser beam, and the scanning mirror can move the laser beam in different directions to achieve adjustment of the cutting path.

Control System

The control system is the intelligent core of the entire laser cutting machine, consisting of various components such as control circuits, computers, and control software. The control system can finely control the laser, including controlling the opening and closing, direction, power, etc. of the laser beam, while also meeting the user’s needs for adjusting and optimizing parameters such as cutting path and speed.

Water Cooling System

The laser of the CO2 laser cutting machine generates a large amount of heat during operation, and the water cooling system can effectively dissipate this heat. The water cooling system mainly includes components such as circulating water pump, water tank, radiator, etc., which together form a closed circulating system that can quickly discharge the heat generated inside the laser.

The above are the main components of a CO2 laser cutting machine, and each part plays a very important role and cannot be missing. By understanding these components, we can better understand the structure and principle of CO2 laser cutting machines, and thus better apply them for cutting processing.

Basic Differences Between Co2 Laser Cutting Machines And Fiber Laser Cutting Machines

Different Usage Life

The CO2 laser cutting machine relies on an air generator to excite the laser with a wavelength of 10.6 μ m, while the fiber laser cutter is excited by a solid laser generator with a wavelength of 1.08 μ m. Due to its wavelength of 1.08 μ m, fiber laser cutting machines can propagate over long distances, and the service life of laser generators is longer than that of CO2 laser tubes.

Different Component Losses

Additionally, the propagation methods of these two machines are completely different. On the one hand, CO2 laser generators rely on reflectors to transmit laser from the oscillator to the processing point. It is necessary to regularly clean the reflector and replace such vulnerable parts. Fiber optic is the factor that enables fiber laser cutting machines to function as a light source. In this way, the fiber laser cutting machine only generates a slight loss. From oscillator to processing point. It is necessary to regularly clean the reflector and replace such vulnerable parts. Although fiber optic is a factor of fiber optic, cutting tools are used in laser cutting machines.

If we consider operating costs, due to complex components and basic design, fiber laser cutting machines are higher than carbon dioxide laser cutting machines in the first stage. However, in the long run, it will bring adverse results, resulting in higher maintenance costs for CO2 laser cutting machines than fiber laser cutting machines.

The operating cost can be divided into two parts: the photoelectric conversion rate and the maintenance cost.

Generally speaking, the photoelectric conversion rate of CO2 laser cutting machines is about 10% -15%, while the photoelectric conversion rate of fiber laser cutting machines is about 35% -40%. If we try to understand this rate literally, you will find that fiber laser cutting machines are at least twice as fast as CO2 laser cutting machines when cutting the same material. This also means that if someone wants to puncture a certain material, CO2 laser cutting machines obviously require more electricity bills. Approximately 10% to 15%, while fiber cutting tools can be at least twice as fast as CO2 cutting tools because they cut the same material. This also means that if someone wants to puncture this material, CO2 laser cutting machines obviously require more electricity bills.

Meanwhile, a CO2 laser generator needs to be maintained every 4000 hours, and after approximately 20000 hours, the fiber laser cutting machine and laser cutting tools need to be maintained.

Different Cutting Materials

If you understand the applications of these two machines, you will find that CO2 laser cutting machines are widely used in non-metallic processing, and fiber laser cutting machines are usually seen as good helpers in the metal related industry. Of course, CO2 laser cutting machines can also cut metal materials, but in recent years they have gradually been replaced by fiber laser cutting machines. Widely used in non-metallic processing, fiber cutting tools can also cut metal materials, but in recent years they have gradually been replaced by fiber laser cutting machines.

When it comes to CO2 laser cutting machines, most people associate them with non-metallic materials such as plastic, wood, glass, MDF board, ABS board, cloth, rubber, leather, etc. It can carve materials with precise shapes and complex textures. Most businessmen working in the manufacturing industry are familiar with fiber laser cutting machines, as they are very common in different industries such as hardware, medical equipment, environmental protection, transportation, etc.

Most people associate it with non-metallic materials such as plastic, wood, glass, MDF board, ABS board, cloth, rubber, leather, etc. It can carve materials with precise shapes and complex textures.

Conclusion

CO2 laser cutting machine is better to cut the non-metallic material. For metal sheet cutting, it is better to choose the fiber laser cutting machine. Currently, fiber laser cutting machine in the the laser cutting machine market is more and more popular, and the CO2 laser cutting machine market share is keep decreasing. CO2 laser cutting machine may be replace by the fiber laser cutting machine in the future.