CNC turret punching machine integrates machine, electricity, liquid, and gas, and is a pressure processing equipment that uses turret punching machine molds to perform punching and shallow drawing deep forming on sheet metal.

The CNC turret punch press machine is composed of a computer control system, mechanical or hydraulic power system, servo feeding mechanism, mold library, mold selection system, peripheral programming system, etc.

The CNC turret punch press is a machining program developed through programming software. The servo feeding mechanism sends the sheet metal to the desired machining position, and the mold selection system selects the corresponding mold in the mold library. The hydraulic power system presses according to the program, automatically completing the machining of the workpiece.

The SC CNC turret punch press is equipped with a 32 station turntable and 2 automatic indexing stations, equipped with an automatic lubrication system and a plate deformation monitoring device.

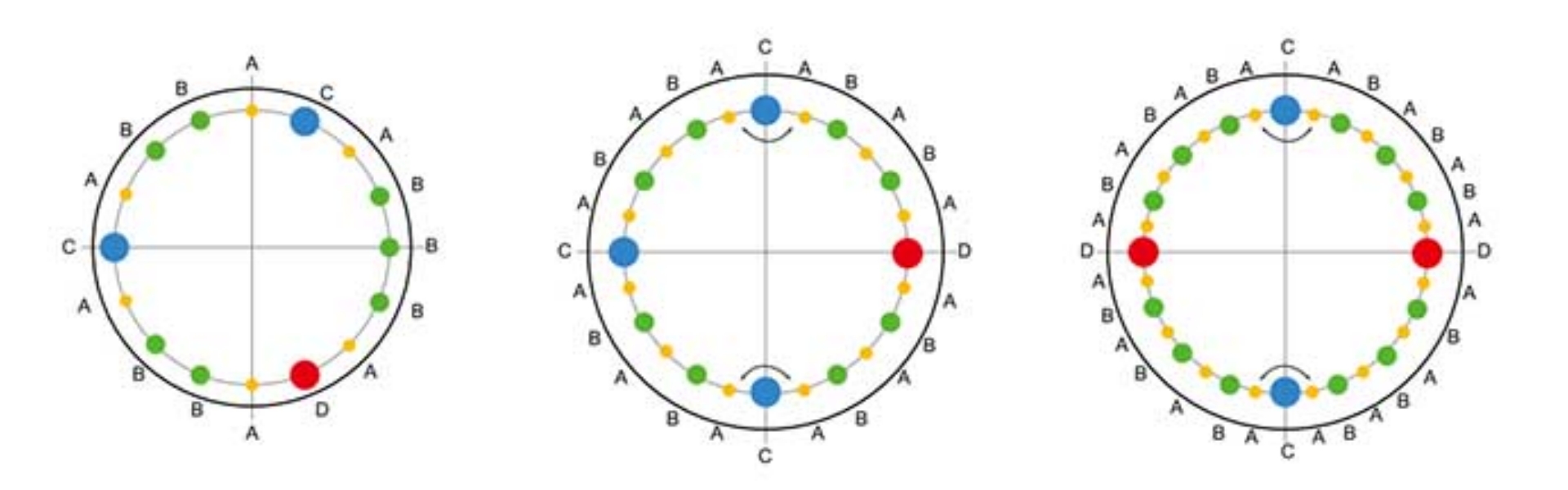

Number of mold workstations | A | B | C | D |

Φ3-Φ12.7mm | Φ12.7 ≤Φ31.7mm | Φ31.7 ≤Φ50.8mm | Φ50.8 ≤Φ88.9mm | |

16 | 6 | 7 | 2 | 1 |

24 | 12 | 8 | 2(Rotating workstation )+1 | 1 |

32 | 16 | 12 | 2(Rotating workstation) | 2 |

The throat depth of CNC turret punching machine refers to the distance from the punching center to the side plate of the bed. The depth of the throat directly determines the width and size of the processed board (i.e. the size of the board processed along the length direction of the bed)

X-axis: The servo drive axis that moves the workpiece along the direction perpendicular to the length of the bed

Y-axis: a servo drive axis that moves the workpiece parallel to the length of the bed

A-axis: Select the rotation axis of the mold for the rotary turret type tool library selection

C-axis: The rotation axis for automatic indexing of the mold, which can rotate the mold at any angle

Universal thick turret molds are generally classified according to the aperture size that the mold can process, which facilitates the selection of molds. It is usually divided into five levels: A, B, C, D, and E.

|

Model |

CNC Mechanical Turret Punch Press |

CNC hydraulic Turret Punch ress |

CNC Fully Servo Turret Punch Press |

||||

|

SKC30-16 |

SKC30-24 |

SKCX30-16 |

SKYC30-24 |

SKYC30-32 |

SKSC30-32 |

SKSC30-36 |

|

|

Rated pressure (KN) |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

|

Workpiece size (mm) |

1250×2500 or 1250×4000 1500×2500 or 1500×4000 |

1250×2500 or 1250×4000 or 1250×5000 1500×2500 or 1500×4000 or 1500×5000 |

1250×2500 or 1250×4000 or 1250×5000 1500×2500 or 1500×4000 or 1500×5000 |

||||

|

Number of workstations |

16 |

24 |

24 |

24 |

32 |

32 |

36 |

|

Maximum punching diameter (mm) |

Φ88.9 |

Φ88.9 |

Φ88.9 |

Φ88.9 |

Φ88.9 |

Φ88.9 |

Φ88.9 |

|

Rotating workstation |

|

|

Φ50.8 |

Φ50.8 |

Φ50.8 |

Φ50.8 |

Φ50.8 |

|

Maximum punching diameter (mm) |

|||||||

|

Number of control axes |

3 |

3 |

4 |

4 |

4 |

5 |

5 |

|

accuracy |

±0.1 |

±0.1 |

±0.1 |

±0.1 |

±0.1 |

±0.1 |

±0.1 |

|

Impact frequency (Hpm) |

160~250 |

160~250 |

160~250 |

0~600 |

0~600 |

0~500 |

0~500 |

|

Punching speed (m/min) |

80 |

80 |

80 |

80 |

80 |

80 |

80 |

|

Maximum plate thickness (mm) |

6 |

6 |

6 |

5 |

5 |

5 |

5 |

|

Air pressure (Mpa) |

0.55 |

0.55 |

0.55 |

0.55 |

0.55 |

0.55 |

0.55 |

SC SHENCHONG CNC SKC30 series turret punch integral welding structure, quenching and tempering treatment to eliminate stress. Strong rigidity and large tonnage ensure long-term stability of accuracy and prolong service life. The advanced and reliable stamping system can automatically select the stroke of different plate thickness materials, and it is very convenient to use special technology for processing.

Advanced CNC servo system, equipped with pressure valve, can accurately control the speed, volume, and pressure of oil flow.

In order to control the RAM stroke distance at both ends, the height and depth of each punch can be programmed with an accuracy of 0.1mm.

The uniquely designed machine structure can reduce preventive maintenance

The servo motor of the AC punching machine can be programmed for various applications.

High speed applications.

Low noise applications.

The hydraulic main transmission system of Bosch Rexroth in Germany can automatically select the stroke for materials of different thicknesses, which is very convenient for special process processing, such as blinds, demolding holes, etc. It has automatic hydraulic overload protection, and the stroke is constant throughout the entire process pressure, making the stamping quality reach a very high level.

Adopting high-performance pneumatic clutch.

The high and low stamping speed can be automatically adjusted.

Continuous stamping with super large step distance.

Unique integral casting support structure.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.