Table of Contents

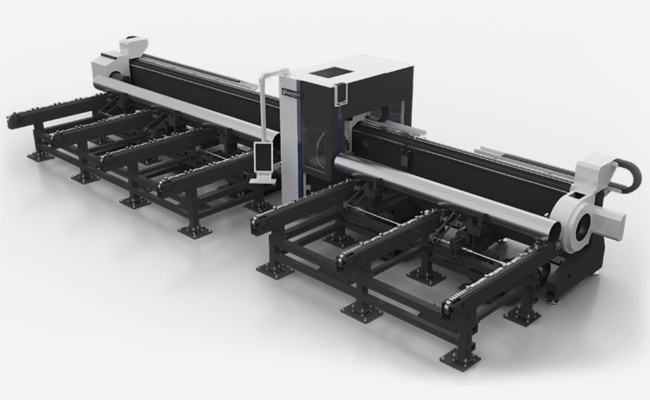

Laser technology has developed rapidly in recent years and has gradually been widely applied in many industries. Laser cutting has gradually evolved from cutting single flat sheets to cutting metal composite materials, such as three-dimensional groove cutting, cutting of irregular pipes, etc. The emergence of professional tube and pipe fiber laser cutting machine has greatly improved the production efficiency of metal composite pipe materials.

What Is A Tube And Pipe Fiber Laser Cutting Machine?

Fiber laser pipe cutting machine is an efficient processing equipment based on fiber laser, specifically used for cutting various types of metal pipes. It combines the high precision, high efficiency, and automation system of fiber lasers, becoming an indispensable equipment in the manufacturing industry, widely used in industries such as aerospace, automotive manufacturing, construction engineering, medical equipment, etc.

Composition Of Pipe Fiber Laser Cutting Machine

The fiber laser tube cutting machine consists of the following main parts:

- Fiber laser: the core component of fiber laser tube cutting machine, responsible for generating high-energy laser beams. Fiber lasers have the advantages of long lifespan, high energy conversion efficiency, and low maintenance costs.

- Numerical Control System: Modern fiber laser cutting machines are equipped with advanced numerical control systems to control the power output of the laser, plan the cutting path, and adjust various process parameters. Numerical control systems can achieve automated processing of metal pipes of different shapes and sizes through programming.

- Mechanical fixtures: In order to ensure the stability of the pipe during the cutting process, fiber laser cutting machines are usually equipped with mechanical fixtures that can automatically grasp and rotate metal pipes. The accuracy of the fixture system directly affects the precision and efficiency of cutting.

- Motion platform: The motion platform is usually connected to a CNC system and used to drive the cutting head to move according to a predetermined trajectory. The motion accuracy of the platform is also an important factor determining the cutting accuracy.

- Cooling system: Due to the large amount of heat generated during laser cutting, fiber laser cutting machines are equipped with cooling systems, usually using water or air cooling methods, to ensure that the equipment maintains normal temperature during high load operation and prevent laser overheating and damage.

- Smoke exhaust system: During the laser cutting process, smoke and metal vapor are generated. The fiber laser pipe cutting machine is equipped with a smoke exhaust system, which can effectively eliminate these exhaust gases and maintain a clean working environment.

Application Fields Of Fiber Laser Tube Cutting Machine

Tube and pipe fiber laser cutting machines are widely used in multiple fields, especially in metal processing and manufacturing, playing an important role.

- Aerospace: The aerospace industry has very high requirements for material processing accuracy. Fiber laser cutting machines can accurately process high-strength metal alloys to meet the complex structural requirements of aerospace components.

- Automobile manufacturing: In the process of automobile manufacturing, many components require precise metal processing, such as frames, exhaust systems, etc. Fiber laser cutting machine can quickly and accurately cut various metal pipes, improving the production efficiency and quality of automotive parts.

- Construction engineering: The use of metal materials such as stainless steel and aluminum alloy is very common in building structures. Fiber laser pipe cutting machine can cut various shapes of metal pipes according to building design requirements, meeting personalized needs in construction.

- Medical equipment: The medical equipment industry requires very high precision and quality of products. Fiber laser tube cutting machines can produce high-precision metal parts, such as surgical instruments, implants, etc.

- Home decoration: In modern home decoration, metal materials are widely used in furniture, doors and windows, decorations, and other aspects. Fiber laser tube cutting machine can produce exquisite metal products according to the designer’s creativity, adding artistic value to home design.

Advantages Of Tube And Pipe Fiber Laser Cutting Machine

Compared with traditional cutting techniques, tube fiber laser cutting machines have the following significant advantages:

- High precision: Fiber lasers have high beam quality and can achieve sub millimeter cutting accuracy, especially suitable for cutting complex curves and shapes. Through precise control of the numerical control system, errors can be controlled within a very small range, which can meet high demand machining requirements.

- High efficiency: The fiber laser cutting machine has a fast cutting speed, especially in the processing of thin-walled metal pipes. Compared with traditional mechanical cutting methods, laser cutting can complete processing in one go without the need for additional polishing and shaping processes, greatly improving production efficiency.

- High degree of automation: tube and pipe fiber laser cutting machines are usually equipped with advanced automation control systems, which can achieve fully automatic processing from loading, cutting to unloading. This not only reduces manual operation errors, but also greatly lowers labor costs.

- Wide range of material applications: tube and pipe fiber laser cutting machine can cut various metal materials, such as stainless steel, aluminum alloy, carbon steel, copper, etc. It can also adjust the laser power according to different materials to meet the cutting needs of different materials.

- Low maintenance cost: Fiber laser has a simple structure, strong durability, and a lifespan of tens of thousands of hours, with low daily maintenance costs. In addition, due to the use of solid fiber media in fiber lasers and the absence of vulnerable parts, the maintenance frequency is low.

- Environmental protection and energy saving: The electro-optical conversion efficiency of the fiber laser tube cutting machine is over 30%, which is lower in energy consumption compared to other lasers. Meanwhile, fiber lasers do not require the addition of any gas during operation, resulting in low emissions and pollution, making them an environmentally friendly processing equipment.

How To Choose A Tube and Pipe Fiber Laser Cutting Machine

Key Points For Purchasing Fiber Laser Tube Cutting Machine

When choosing a fiber laser cutting machine, users need to consider the following aspects based on their actual needs:

- Power selection: Choose the appropriate laser power based on the thickness and type of material being processed. For thinner metal pipes, low-power lasers are sufficient; For thicker materials, high-power lasers are required.

- Cutting accuracy: For high-precision machining requirements, fiber laser pipe cutting machines with high-precision motion platforms and advanced CNC systems should be selected.

- Automation level: If the production scale is large, it is recommended to choose equipment with high automation level, which can reduce manual operation and improve production efficiency.

- After sales service: Fiber laser cutting machine is a high-precision equipment, and the timeliness and quality of after-sales service are very important. Choosing a manufacturer with a good after-sales service system can ensure the long-term stable operation of the equipment.

Price Analysis Of Fiber Laser Pipe Cutting Machine

Fiber laser tube cutting machine is an efficient and precise processing equipment widely used in various industries, such as automobile manufacturing, aerospace, construction engineering, etc. With the increasing demand and technological progress, the types and functions of fiber laser tube cutting machines in the market are becoming more and more diverse, and there are also significant price differences. So, what are the factors that affect the price of fiber laser tube cutting machines? This article will provide a detailed analysis of the price of fiber laser tube cutting machines and offer purchasing recommendations for consumers.

The Main Influencing Factors On The Price Of Fiber Laser Tube Cutting Machine

Laser Power

The power of fiber laser is one of the key factors determining the price of tube and pipe fiber laser cutting machine. The power of a laser is usually measured in watts (W), with common power ranges on the market ranging from 500W to 12000W or even higher. The higher the power, the higher the price naturally.

Low power (500W-1000W) fiber laser cutting machines are suitable for cutting thin-walled metal pipes, with relatively low prices, usually between $28,000 and $71,000. Equipment with high power (such as 3000W or more) can cut thick walled metal pipes, and the price may be between $140,000 to $280,000 or even higher.

Automation Level

Modern fiber laser cutting machines generally have a high degree of automation, but the degree of automation varies among different devices. Some high-end equipment has functions such as fully automatic loading, unloading, rotation, and positioning, which require almost no manual intervention, while some low-end equipment requires partial manual operation.

The higher the degree of automation, the more expensive the equipment. For example, a fiber laser pipe cutting machine with a fully automatic fixture system may be more than 30% more expensive than manual equipment. The price of this fully automated equipment is usually between $140,000 and $420,000.

Cutting Size And Applicable Range Of Pipes

The applicable range and cutting size of tube and pipe fiber laser cutting machine will also affect the price. Some devices can cut pipes of different diameters, and even handle non-circular pipes such as square pipes, rectangular pipes, elliptical pipes, etc. The wider the cutting ability, the higher the structural complexity of the equipment, and the cost will also increase accordingly.

If the equipment can handle pipes with large diameters (such as over 300 millimeters), the price is usually higher. In addition, some devices support cutting of multiple materials (such as stainless steel, aluminum alloy, carbon steel, etc.), and this versatility will also increase the price of the equipment.

Brand And Place Of Origin

The brand and manufacturer of the fiber laser cutting machine are important factors affecting the price. The price difference between domestic manufacturers and imported equipment is significant. The price of fiber laser cutting machines from well-known China brands usually ranges from $70,000 to $280,000, depending on their functions and configurations. High end brand equipment from Germany, the United States, Japan, and other places, due to advanced technology and exquisite craftsmanship, usually have higher prices, possibly ranging from $280,000 to $710,000 or even more expensive.

Selection Of Core Components

The core components of fiber laser tube cutting machine, such as fiber laser, cutting head, CNC system, servo motor, etc., will have a significant impact on the price. For example, imported fiber lasers (such as IPG, nLIGHT, etc.) have higher prices and better performance stability, so equipment using these brands of lasers often costs 30% to 50% more than domestic lasers. Similarly, imported CNC systems and servo motors will also increase the overall price of the equipment.

After Sales Service And Warranty Period

The maintenance and after-sales service of the fiber laser cutting machine will also affect the price. Some high-end equipment manufacturers offer a warranty period of up to two or three years, including free on-site maintenance, remote monitoring and diagnosis services. These after-sales guarantees are usually reflected in the initial purchase price of the equipment. Manufacturers with comprehensive services usually have higher prices, but long-term usage costs will be reduced.

Price Range Of Different Types Of Fiber Laser Cutting Machines

Entry Level Fiber Laser Tube Cutting Machine

The entry-level fiber laser pipe cutting machine is suitable for small factories or small batch production, usually equipped with low-power lasers (500W to 1000W), with relatively simple functions, suitable for cutting thin-walled metal pipes. The price is generally between $28,000 and $70,000. Although these devices are relatively inexpensive, they are already sufficient to meet the basic cutting needs of some small and medium-sized enterprises.

- Laser power: usually between 500W and 1000W, suitable for cutting thin metal pipes such as stainless steel, carbon steel, etc.

- Cutting ability: Suitable for thin-walled pipes, typically cutting thicknesses not exceeding 3 millimeters.

- Manual feeding and positioning: Most entry-level equipment does not have fully automatic feeding function and requires manual intervention for material positioning and clamping.

- Manual adjustment of cutting head: The height adjustment and focal length adjustment of the cutting head usually require manual operation, with less support for automatic focusing function.

- Basic CNC system: Adopting a relatively simple CNC system that can meet basic straight and curved cutting needs, but does not have complex path planning or intelligent operation functions.

- Mainly suitable for common metal pipes, such as stainless steel, carbon steel, aluminum alloy, etc. But its performance is limited in cutting high reflective materials such as copper, silver, etc.

- The accuracy is relatively basic and can meet general processing requirements, but it performs slightly weaker in high-precision and complex shape processing.

- Laser and cutting heads are usually selected from domestic brands or relatively basic imported components, with relatively short performance and lifespan.

Mid End Pipe Fiber Laser Cutting Machine

Mid end devices are generally equipped with medium power lasers (1000W to 3000W), which can cut various metal materials with higher cutting accuracy and efficiency. Usually equipped with partial automation functions, such as automatic feeding systems and rotating fixtures. The price ranges from $70,000 to $140,000, suitable for medium-sized enterprises and mass production needs.

- Laser power: usually between 1000W and 3000W, suitable for cutting medium thickness metal pipes, with a cutting thickness range typically between 3 and 10 millimeters.

- Cutting ability: It can cut various thicknesses and types of metal pipes, including stainless steel, carbon steel, aluminum, brass, etc.

- Semi automatic feeding system: equipped with semi-automatic feeding and positioning functions, reducing manual intervention and improving production efficiency. Some models are capable of automatic fixture adjustment.

- Automatic focusing cutting head: The cutting head is equipped with an automatic focusing function, which can automatically adjust the focus according to the material thickness, improving cutting quality and efficiency.

- Advanced CNC System: Adopting a more comprehensive CNC system, supporting programming and path planning for complex graphics, enabling more intelligent operations and reducing human errors.

- The applicable material range is wider, and it can handle various metals such as stainless steel, carbon steel, aluminum alloy, copper, brass, etc., with improved cutting performance in high reflective materials.

- The cutting accuracy has been improved, making it suitable for production needs that require high machining accuracy. Usually, the error is controlled within 0.1 millimeters, which can process more complex shapes and patterns.

- Core components such as lasers, cutting heads, servo motors, etc. are mostly imported brands such as IPG, nLIGHT, PRECITEC, etc., ensuring the long-term stability and efficient performance of the equipment.

High End Fiber Laser Tube Cutting Machine

High end tube and pipe fiber laser cutting machines are usually equipped with high-power lasers (3000W to 6000W) and support fully automated production processes. The equipment has multifunctional cutting capabilities and is suitable for high-precision cutting of large diameter and thick walled pipes. It is commonly used in industries with high requirements such as aerospace and automotive manufacturing. This type of equipment is the most advanced, with high automation and intelligence, capable of handling various complex shapes and highly reflective materials, and typically priced between $140,000 to $428,000, or even higher. This type of device configuration.

- Laser power: usually ranging from 3000W to 6000W or even higher, suitable for cutting thick walled metal pipes with a thickness of over 20 millimeters.

- Cutting ability: It can cut metals of various thicknesses and materials, including highly reflective metals such as copper, silver, gold, etc.

- Fully automated loading and unloading system: A fully automated loading, unloading, and fixture system that can achieve unmanned operation, significantly reducing manual intervention and improving production efficiency.

- Automatic adjustment and intelligence: intelligent functions such as automatic focusing, automatic detection of cutting status, real-time monitoring system, etc., can self adjust and optimize the operating status of the equipment to ensure the best cutting effect.

- Top level CNC system: Adopting the world’s leading CNC system, it supports functions such as 3D cutting, complex curve trajectory, dynamic path adjustment, etc., and can adapt to the most complex machining needs.

- Capable of adapting to all types of metal materials, including high-strength alloys, thick walled pipes, and high reflective materials. The equipment has higher flexibility and wide material adaptability.

- High precision, suitable for demanding industrial production, with errors typically controlled within 0.05 millimeters or even lower, enabling complex surface machining and high-precision cutting.

- All core components are made of world-class brands, such as German IPG lasers, PRECITEC cutting heads, and Japanese Yaskawa servo motors. The core components of this type of equipment have a long lifespan and stable performance, making them suitable for long-term high-intensity work.

Customized Tube And Pipe Fiber Laser Cutting Machine

Some companies may require customized fiber laser cutting machines to meet special production needs. The price of customized equipment is relatively flexible and depends on specific requirements. Usually, the price of customized equipment will be 20% to 50% higher than standard equipment, depending on the special features, size requirements, and other customized technical parameters of the equipment.

Grade | Laser Power | Automation Level | CNC System | Material | Cutting Precision | Core Parts |

Beginner | 500W-1000W | Manual feeding | Basic CNC system | Common metal pipes | 0.2-0.5mm | Basic China Brands |

Mid end level | 1000W-3000W | Semi automatic feeding | Advanced CNC system | Multiple metal materials | 0.1mm | Japan Brands |

High end level | 3000W Above | Fully automatic feeding | Top level CNC system | All metal materials | 0.05mm | European Brands |

Development Trend of Fiber Laser Pipe Cutting Machine

With the advancement of technology, fiber laser cutting machines are developing in the following directions:

Intelligence and automation: Future fiber laser cutting machines will be more intelligent and automated, capable of achieving a higher degree of unmanned operation. Through the Internet of Things and artificial intelligence technology, devices can monitor their operating status in real time, automatically adjust cutting parameters, and further improve production efficiency.

The application of high-power lasers: With the emergence of high-power fiber lasers, fiber laser cutting machines will be able to cut thicker metal pipes and further improve efficiency and accuracy. The application of high-power lasers will expand the scope of equipment and meet the needs of more industries.

Energy saving and environmental protection technology: Future fiber laser cutting machines will pay more attention to energy saving and environmental protection, by further improving the electro-optical conversion efficiency of the laser and reducing energy consumption. At the same time, the equipment will use more environmentally friendly materials and manufacturing processes to reduce pollution during the production process.

Multi functional integration: Future fiber laser cutting machines will integrate more functions, not only for cutting, but also for various processing techniques such as welding and drilling. The integration of multiple functions will provide users with more processing options, improving the flexibility and practicality of equipment.

Price trend: With the continuous advancement of technology, the price of fiber laser tube cutting machines is showing a gradual downward trend. In the early days, due to technological barriers and limited market demand, the price of fiber laser tube cutting machines was relatively high, especially for high-power and imported equipment. However, with the rapid development of domestic laser technology and the intensification of market competition, the manufacturing cost of equipment has been reduced, especially with domestic brand equipment being more affordable.

Conclusion

A professional tube and pipe fiber laser cutting machine can replace multiple processes such as drilling, sawing, etc., and there is no need to polish the finished product in the later stage. One device can complete the work of traditional four devices in only one-fifth of the time required for traditional processes, and can produce the same or even better finished product. Professional laser cutting machines have successfully changed the current pipe processing market. The different levels of configuration of fiber laser cutting machines meet different production needs. The entry-level is suitable for small-scale production, the mid-range is suitable for medium scale production, and the high-end is aimed at industrial manufacturing enterprises that require high precision and efficiency. When making a purchase, enterprises should choose the appropriate equipment grade based on their own needs, budget, and future development plans to ensure efficient return on investment. The price of fiber laser tube cutting machine is influenced by various factors, ranging from tens of thousands to millions of yuan. When choosing equipment, enterprises need to make reasonable choices based on their actual needs, budget, and planning for future production capacity.

![Intelligent Sheet Metal Processing [FAQ]](https://www.shen-chong.com/wp-content/uploads/2025/11/Intelligent-Sheet-Metal-Processing-FAQ.jpg)