Table of Contents

Reasonable stainless steel bending machine selection requires determining the machine model and parameters according to specific processing requirements. Selecting a press brake bending machine with appropriate parameters and models can not only improve work efficiency, but also reduce production costs and extend the using life of equipment and tools.

1. Key factors for stainless steel bending machine selection

1) Material properties

Features of stainless steel:

Stainless steel has high strength and hardness, and requires greater pressure when bending.

It has strong elastic recovery, and the bending angle may need to be compensated.

Recommended pressure coefficient:

The pressure coefficient of stainless steel is about 1.5 times that of ordinary steel. For example, if ordinary steel requires 100 tons of pressure, stainless steel may require 150 tons.

2) Plate specifications

Plate thickness:

The pressure (tonnage) of the bending machine must meet the requirements of the maximum plate thickness.

Plate length:

The working table length of the bending machine must cover the maximum bending length of the plate.

3) Bending process

Bending angle:

When bending stainless steel, high angle accuracy is required, so it is recommended to choose a CNC press brake machine.

Bending shape:

If complex shapes are required (such as multi-angle, deep U-shape, etc.), the mold compatibility and flexibility of the bending machine need to be considered.

4) Processing volume

Small batch processing:

Manual or small CNC bending machines can be selected.

Massive production:

High-efficiency hydraulic CNC press brake machines or servo hybrid press brake are recommended.

Choosing a suitable stainless steel bending machine requires determining the machine model and parameters based on specific processing requirements. The following are the factors that need to be considered when selecting bending machine parameters and the recommended selection process.

2. How to determine the main parameters of the bending machine?

1) Select the press brake tonnage according to the thickness of the plate

Pressure requirements:

Bending stainless steel requires greater pressure than ordinary carbon steel, and the equipment tonnage must meet the requirements of plate thickness and length.

Calculation formula:

Bending force (tons) ≈ 1.42 × plate thickness × plate width ÷ V-groove width

(V-groove width is usually 8-10 times the plate thickness)

Example:

A stainless steel plate with a thickness of 1mm and a length of 1m, using a 10mm groove width mold, requires a pressure of about 50 tons.

Equipment selection:

- Thin plate (≤3mm): You can choose a small tonnage hydraulic bending machine or a mechanical bending machine.

- Medium and thick plates (3-10mm): A medium-sized hydraulic bending machine is required, with a pressure range of 100-300 tons.

- Thick plates (>10mm): A large tonnage hydraulic bending machine is required, with a pressure of more than 300 tons.

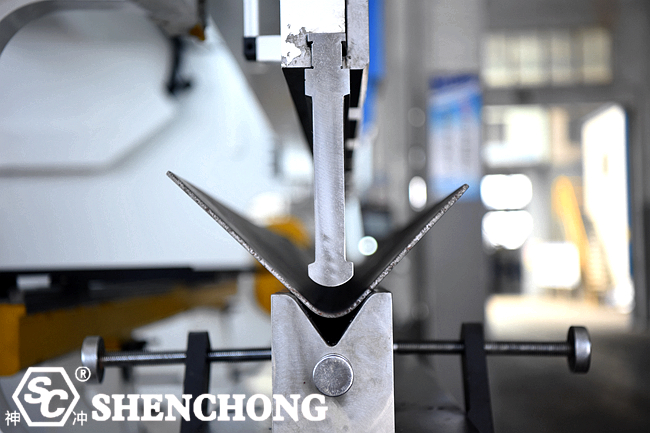

2) Select the mold according to the bending radius

Relationship between the bending radius and the width of the mold slot:

The bending radius is usually 1-3 times the thickness of the plate.

The width of the mold slot (V-groove width) needs to be selected according to the thickness of the plate. The recommended value is:

V-groove width ≈ 8-10 times the thickness of the plate (for example, for a 3mm thick plate, a mold with a slot width of 24-30mm should be selected).

Mold type selection:

- Sharp mold: used for small radius or right-angle bending.

- Arc mold: suitable for large radius or curved surface bending.

- Multi-V mold: suitable for processing requirements of various thicknesses and angles, with strong flexibility.

3) Select equipment and tools according to the bending angle

Equipment selection:

- Precision angle bending: It is recommended to use a CNC bending machine (CNC), which can achieve high-precision angle control.

- Ordinary angle bending: Hydraulic bending machine or mechanical bending machine can meet the needs.

Mold selection:

Small angle (<90°): Use a sharp V-shaped mold, and the mold angle should be smaller than the target bending angle.

Large angle (>90°): You can choose a wide slot mold or an arc mold.

4) Select the type of equipment according to processing accuracy

High precision requirements:

CNC press brake machine with automatic compensation function is selected, which is suitable for complex parts and mass production.

Application areas: aerospace, medical equipment, automotive parts.

General precision requirements:

Hydraulic press brake or mechanical press brake is selected, which is suitable for general industrial processing.

Application areas: architectural decoration, home appliance manufacturing.

5) Select auxiliary tools according to the needs of stainless steel surface protection

Protective gasket:

Use polyurethane or nylon gasket to prevent the mold from scratching the stainless steel surface.

Suitable for parts with high surface requirements, such as decorative parts, kitchen utensils, etc.

Anti-scratch film:

Apply the film to protect the stainless steel surface before bending to avoid scratches during processing.

Particularly suitable for polished or mirrored stainless steel.

Flexible mold:

Flexible mold is made of special materials and can protect the stainless steel surface during bending.

6) Select the bending machine table size according to the length of the plate

The plate length matches the table size:

The bending machine table length must be greater than the plate length.

Long plate processing requires the use of large bending machines or multi-machine linkage systems.

Segment processing requirements:

For super-long plates, segmented bending or special fixtures can be used for auxiliary processing.

7) Select the degree of equipment automation according to the processing batch

Small batch production:

You can choose a manual bending machine or a common hydraulic bending machine, which is low cost and high flexibility.

Large batch production:

CNC bending machines (CNC) or automated bending units are used, which are efficient and suitable for standardized production.

8) Select special tools according to the bending shape

Multiple bending:

Complex parts require multi-station molds or special forming molds.

Special-shaped bending:

Non-linear bending requires a roller bending machine or a special mold.

Small bending edge:

Small edge bending requires a special narrow mold to ensure processing accuracy.

9) Other selection considerations

Material characteristics:

High-hardness stainless steel (such as 304, 316) requires a high-strength mold.

Material with severe work hardening needs to consider preheating or multiple bending.

Equipment brand and service:

Choose a reliable brand to ensure equipment stability and after-sales service quality.

Equipment maintenance and care:

Regularly check the hydraulic system and mold status to ensure processing accuracy and equipment life.

3. Basic selection process of stainless steel bending machines

Clear processing requirements:

- Maximum plate thickness and length.

- Bending angle and shape.

- Production volume and precision requirements.

Determine the type of equipment:

- Small and medium batches: ordinary hydraulic bending machine.

- High precision, large batches: CNC or servo CNC bending machine.

Choose a suitable brand:

- China brands: Shenchong, Jinfangyuan, Yawei, etc., with high cost performance.

- International brands: AMADA, TRUMPF, LVD, etc., with superior performance.

Field inspection and testing:

- Ensure that the equipment performance meets the actual processing needs.

- Check after-sales service capabilities.

4. Recommended types of stainless steel press brakes

1) Manual bending machine

- Applicable scenarios: small batch production, thin plates (<2mm).

- Advantages: low cost, simple operation.

- Disadvantages: low efficiency, average precision.

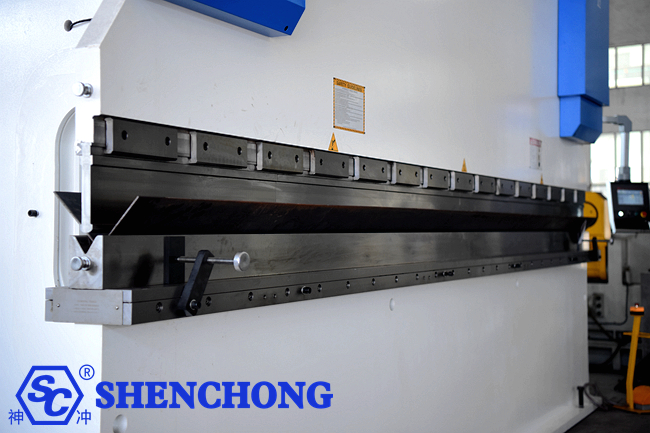

2) NC press brake

- Applicable scenarios: medium and thick plate processing, suitable for mass production.

- Advantages: large bending force, suitable for high-strength materials such as stainless steel.

- Disadvantages: high energy consumption, high maintenance cost.

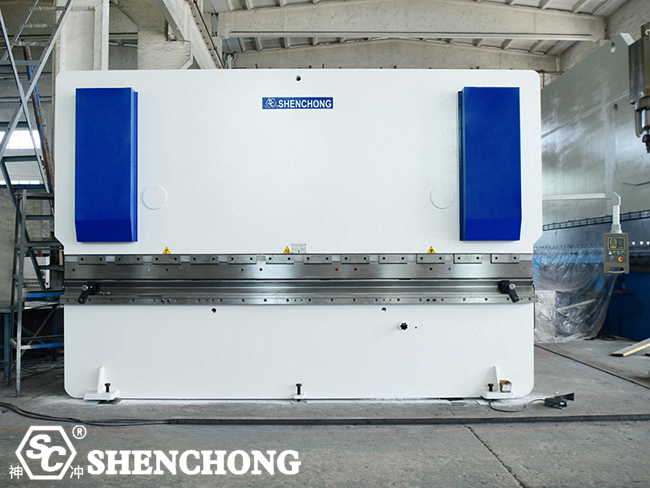

3) CNC press brake

- Applicable scenarios: high precision, mass production.

- Advantages: high precision, programmable operation. Supports complex shape bending.

- Disadvantages: high initial cost.

4) Servo CNC press brake

- Applicable scenarios: high-end processing scenarios, pursuing high efficiency and environmental protection.

- Advantages: low energy consumption, smooth operation. Higher bending precision.

- Disadvantages: expensive equipment.

Recommended models (example):

- AMADA RG series: high-precision CNC press brake machine, suitable for stainless steel processing.

- TRUMPF TruBend series: German brand, servo CNC, suitable for high-end processing scenarios.

- SHENCHONG WDK series: high bending accuracy, energy saving, low noise. Equipped with robots, it can be made into an unmanned bending unit.

5. Summary

The stainless steel bending machine selection needs to comprehensively consider factors such as plate thickness, bending angle, precision requirements, surface protection and production batch. Reasonable selection can not only improve processing efficiency and quality, but also reduce production costs and extend the service life of equipment and tools.

Click here to know more about stainless steel bending:

Stainless Steel Sheet Bending Guide