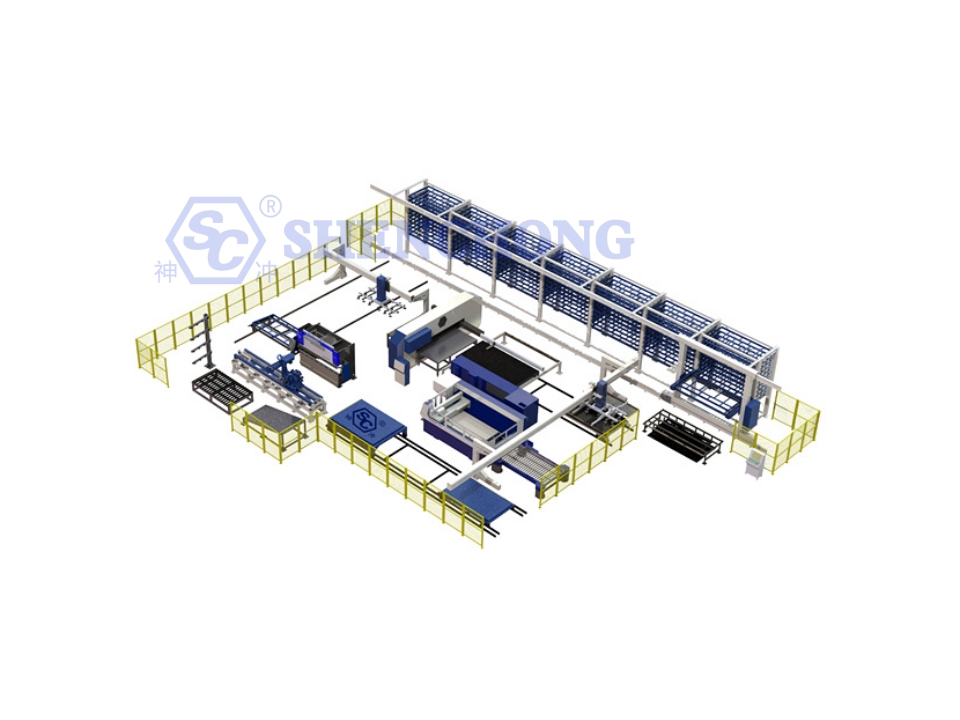

The sheet metal processing automation level of industrial manufacturing will become increasingly high, and the application of MES systems will also become increasingly widespread. SHENCHONG laser cutting loading unloading system, intelligent metal sheet storage system, robotic press brake combine as automation production line solves the problem of reasonable allocation of sheet metal processing tasks, greatly improving the sheet metal processing ability, and also improving the automation level of sheet metal processing, reducing the labor intensity of workers.

Currently, since laser cutting machine is the most popular sheet metal processing machine, laser cutting automation line is the most widely used automation solution. Laser cutting machines have currently improved production efficiency for industrial manufacturing. With the continuous progress of technology, the combination of fiber laser cutting machines and intelligent technology has led to the birth of laser cutting automated production lines. The fully automatic production method has saved labor for the production side and improved production efficiency.

For factories that use laser cutting machines to process sheet metal or pipes in large quantities, especially those with 2 or more laser cutting machines, using laser cutting automated production lines can greatly reduce labor costs and save space for equipment and raw material stacking.

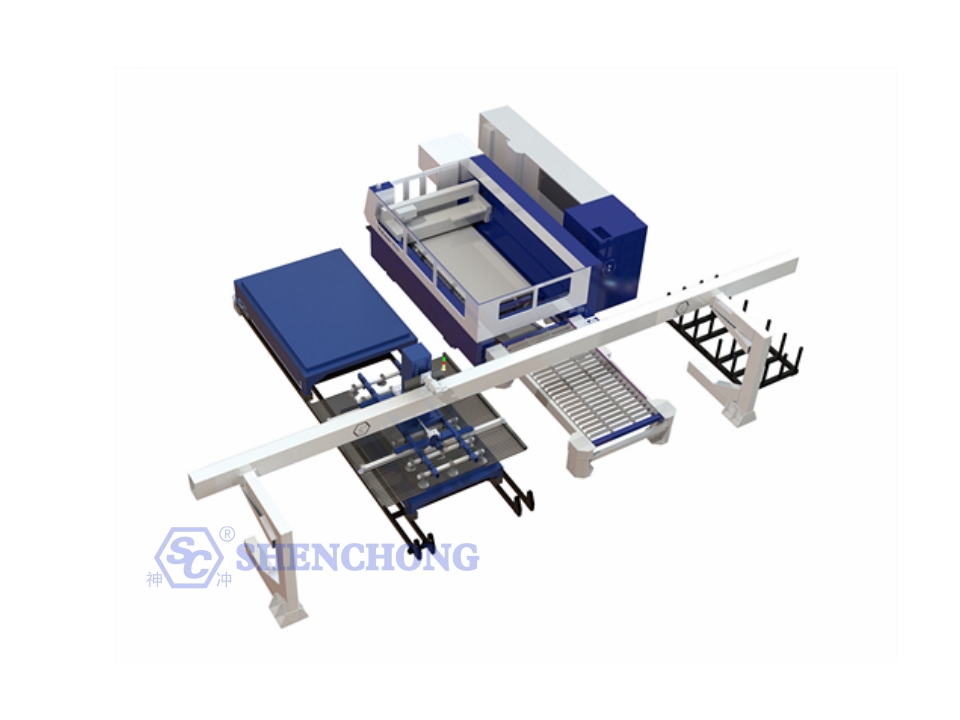

Laser cutting machine automation is also called automatic laser cutting machine flexible production line, which is combined with at least one set of fiber laser cutting machine and other related automatic equipment. For example, one set of sheet plate laser cutting machine + one set of sheet metal storage tower or 2 sets of fiber laser cutting machines + 1 set of automatic loading/unloading system.

SHENCHONG provides laser cutting machine automatic system for sale, which means we have excellent R&D team and can design the automatic proposals based on your requirements.

Also sheet metal automation is not only has laser cutting automation, but also includes many other automatic machine production line. SC provides automation service to build the unman full intelligent factory to reach the industry 4.0.

Other sheet metal automatic production production lines:

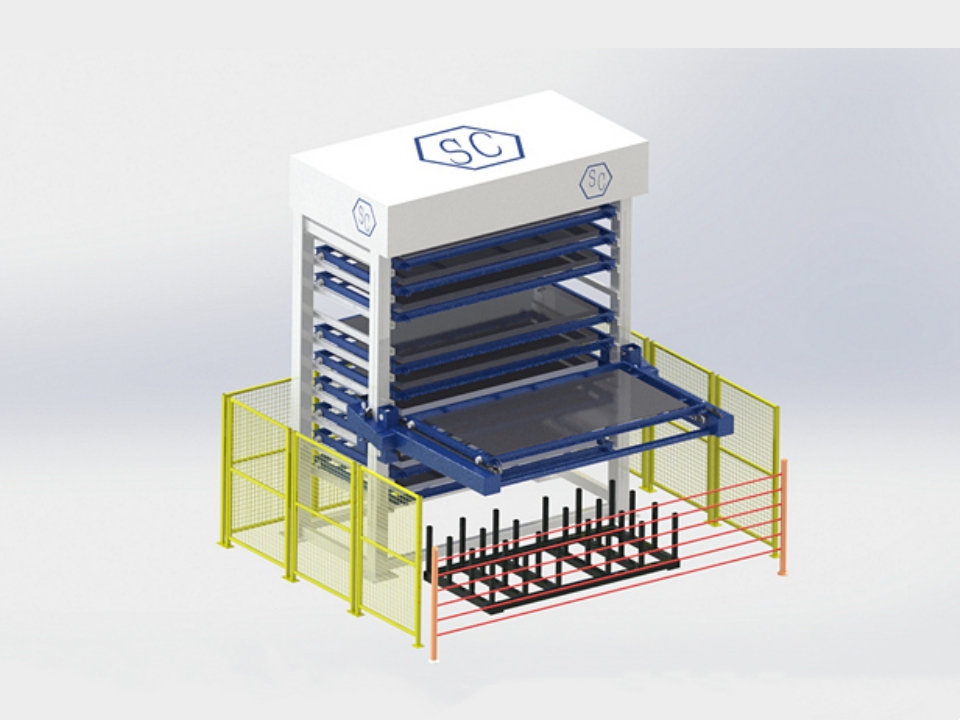

SC SHENCHONG has launched the intelligent sheet metal material storage system, providing sheet metal workshop with the full automatic storage solution. Intelligent metal sheet storage tower save working space, intelligently save the raw materials, and can automatically load and unload the plates and profiles.

Automatic loading unloading system is an automatic handling equipment that can connect with automatic metal storage system, laser cutting machine, turret punch press, plate shearing machine and many other sheet metal processing machinery to reduce the workload and protect the operation safety.

Automatic metal deburring machine completely liberating the hands of workers not only greatly improves work efficiency, but also reduces the cost of work.

It removes burrs from all directions, 360 degree without dead corners, even some hidden seam burrs can be removed. And the force is even, the effect is very good.

SC provides all kinds of sheet metal automatic production line for sale. As a professional metal automatic production line manufacturer, we can provide all production line solutions, including intelligent storage, automatic cutting, automatic bending, automatic punching and automatic welding.

The workers relieved the harmful tasks through automated units. Your employees will appreciate your protection from the dangers of working in the factory.

According to different tasks, laser cutting automatic production line can complete tasks for three to five people. In addition to saving labor, lower heating requirements can be automated to greatly save energy. The production line has achieved program automation, improved part accuracy, and thus reduced material waste during operation.

Automatic laser cutting machine production line can work at a constant speed without human supervision, 24 hours a day, 7 days a week.

Robotsused in the production line are built on small bases to adapt to small areas.

Machines and computers work at consistent and constant speeds. Therefore, when controlled by automated systems, automated manufacturing processes have longer length, stability, and stability.

Your customers will think you are a professional supplier when you have automatic laser cutting production line.

The sheet metal laser intelligent production line refers to a production line that utilizes advanced technology, equipment, and software systems to achieve automated processing and production in the sheet metal idustry.

The process of processing sheet metal work-pieces requires multiple steps such as material storage, laser cutting, bending forming, welding, etc., usually requiring the joint operation of multiple workers to complete.

The intelligent sheet metal production line achieves fully automated processing and production through the coordination of automation equipment and software systems, thereby improving production efficiency, reducing production costs, and reducing waste of human resources.

With the continuous progress of technology, the sheet metal industry is also continuously improving its production efficiency and quality. The automated flexible production line for sheet metal is a new type of production method that can automate the sheet metal processing process, improve production efficiency, reduce costs, and improve product quality.

The automated flexible production line for sheet metal has advantages such as high production efficiency, low cost, and good product quality. It can significantly improve the production efficiency of sheet metal processing, reduce manual operations, and reduce production costs. At the same time, it can also improve product quality and ensure the accuracy and consistency of sheet metal processing.

The feeding robot is one of the core equipment of the sheet metal automated flexible production line. It can automatically remove raw materials from the sheet metal warehouse and accurately deliver them to the working table of processing equipment. In this way, it can save manpower and time, and improve production efficiency.

Laser cutting machine is an important equipment in sheet metal processing, which can accurately cut various shapes of sheet metal. The laser cutting machine uses a high-energy density laser beam for cutting, with fast cutting speed and good cutting quality, which can meet different cutting requirements.

CNC press brake machine is a device that bends cut sheet metal. It adopts digital control technology to accurately control the bending angle and bending radius of sheet metal, thus achieving high-precision machining.

Automatic welding machine is a device that welds sheet metal together, which can automatically complete the positioning, fusion, and cooling of sheet metal. The automatic welding machine adopts high-frequency arc welding technology, with fast welding speed and good weld quality, which can meet different welding requirements.

Sheet metal automatic production line connects these kinds of machines by using loading/unloading system or robots.

(1) Multi process and multi process production management. This includes laser cutting, bending, welding, polishing, transportation, storage, quality inspection, and other processes.

(2) Integration of multiple systems and devices. Such as ERP, MES, WMS, PLM, CAM, CNC, PLC, barcode systems, etc.

(3) Automatic scheduling of production orders. ERP order correlation, automatic order scheduling, automatic scheduling of equipment task orders, real-time feedback of production performance, flexible hybrid production, etc.

(4) Multi variety and small batch automatic typesetting and sorting. This includes automatically associating orders, layout diagrams, etc.

(5) Warehouse inventory management. Not only raw material warehouses, but also the warehousing of finished and semi-finished products, as well as the management of line side warehouses.

(6) Barcode management and quality traceability. And the spraying, pasting, scanning, and tracing of raw materials.

(7) Visualization of production line signage and management. Real time display of production status, equipment status, work efficiency, and other data.

(8) Data analysis and application. Such as predictive maintenance, fault alarm analysis, etc.

This is depends on your requirement. We can design the whole project based on your needs. Please contact with our sales to discuss your plan. For example, tell us if you need metal storage tower? Show us your factory layout, your production mass requirements, and you budget.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.