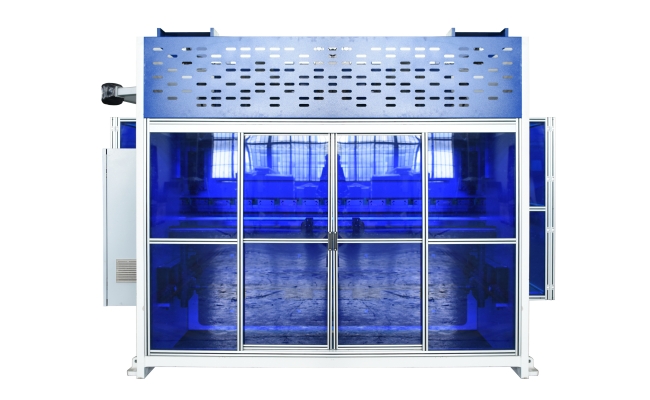

The WDK series CNC servo hybrid press brake machine is a high-precision bending machine that controlled by a CNC control system and a magnetic grating ruler, and according to the forward and reverse rotation of the oil pump and the servo main motor to adjust the Y1 and Y2 axes.

Because servo hybrid press brake is driven by the servo motor and pump, it is also called as servo pump press brake or electric servo press brake machine.

WDK servo hybrid is the most high end press brake type in the market. Its biggest feature is the combination of hydraulic and electrical systems, achieving a hybrid oil electric bending method. During the bending process, the hydraulic system is mainly responsible for providing bending force, while the electrical system is responsible for providing bending angle and bending speed. The combination of the two can achieve efficient and accurate bending operations, while also greatly improving the production efficiency and bending accuracy of the machine.

SC SHENCHONG CNC hybrid servo press brake for sale models: 40Tons – 800Tons

|

Model |

Nominal Pressure |

Length of Table |

Distance between housings |

Throat Depth |

Stroke |

Open height |

Overall dimension |

Weight |

|

kN |

mm |

mm |

mm |

mm |

mm |

Lx W x H mm |

T |

|

|

63T/2000 |

630 |

2000 |

1500 |

320 |

160 |

400 |

2540*1640*2225 |

4.3 |

|

63T/2500 |

2500 |

2000 |

3040*1640*2225 |

4.8 |

||||

|

80T/2500 |

800 |

2500 |

2000 |

400 |

160 |

410 |

3050*1650*2305 |

6 |

|

100T/2500 |

1000 |

2500 |

2000 |

400 |

200 |

450 |

3060*1690*2425 |

6.4 |

|

100T/3200 |

3200 |

2660 |

3720*1690*2475 |

7.3 |

||||

|

100T/4000 |

4000 |

3200 |

4500*1690*2545 |

8.8 |

||||

|

130T/2500 |

1300 |

2500 |

2000 |

400 |

200 |

450 |

3080*1760*2500 |

7.1 |

|

130T/3200 |

3200 |

2660 |

3740*1760*2535 |

8.2 |

||||

|

130T/4000 |

4000 |

3200 |

4520*1760*2610 |

9.5 |

||||

|

170T/2500 |

1700 |

2500 |

2000 |

400 |

200 |

470 |

3100*1830*2520 |

8.7 |

|

170T/3200 |

3200 |

2660 |

3760*1830*2620 |

10.2 |

||||

|

170T/4000 |

4000 |

3200 |

4540*1830*2720 |

11.4 |

||||

|

170T/6000 |

6000 |

4800 |

6600*1950*2980 |

16 |

||||

|

200T/3200 |

2000 |

3200 |

2660 |

400 |

200 |

470 |

3760*1880*2670 |

10.7 |

|

200T/4000 |

4000 |

3200 |

4540*1880*2770 |

12.2 |

||||

|

200T/6000 |

6000 |

4800 |

6600*2200*3150 |

19 |

||||

|

250T/3200 |

2500 |

3200 |

2660 |

400 |

250 |

490 |

3780*1980*2860 |

14.1 |

|

250T/4000 |

4000 |

3200 |

4560*1980*2960 |

16 |

||||

|

250T/6000 |

6000 |

4800 |

6600*2250*3310 |

22 |

||||

|

320T/3200 |

3200 |

3200 |

2660 |

400 |

250 |

500 |

3800*2080*3090 |

17.2 |

|

320T/4000 |

4000 |

3200 |

4580*2080*3090 |

19.5 |

||||

|

320T/6000 |

6000 |

4800 |

6600*2250*3500 |

28 |

||||

|

400T/4000 |

4000 |

4000 |

3200 |

400 |

300 |

605 |

4580*2460*3600 |

26 |

|

400T/5000 |

5000 |

4000 |

5600*2460*3750 |

30 |

||||

|

400T/6000 |

6000 |

4800 |

6600*2460*3950 |

32 |

||||

|

500T/4000 |

5000 |

4000 |

3200 |

600 |

300 |

615 |

4600x2800x4900 |

30 |

|

500T/5000 |

5000 |

4000 |

5600x2900x5100 |

35 |

||||

|

500T/6000 |

6000 |

4800 |

6600*2800*4150 |

46 |

||||

|

630T/5000 |

6300 |

5000 |

4000 |

600 |

300 |

650 |

5600x3000x5250 |

47 |

|

630T/6000 |

6000 |

4800 |

6600x3100x4200 |

56 |

||||

|

800T/6000 |

8000 |

6000 |

4800 |

700 |

350 |

710 |

5600x3450x5500 |

65 |

When the electric servo hybrid CNC press brake machine is in standby mode, the motor does not rotate, so the machine is in a silent state when not in operation.

Because the hybrid servo CNC press brake basically does not require energy consumption in standby and fast mode, and the oil consumption of the oil electric hybrid bending machine is only one-third of that of the electric hydraulic synchronous machine, its oil temperature is controllable and will not significantly increase during operation, and there is no need to change hydraulic oil for three years generally.

Due to the frequency response of the servo motor being much higher than that of the proportional valve, the bending cycle time of the CNC hybrid servo press brake machine is 30% faster than that of the synchronous hydraulic CNC press brake bending machine.

Conventional press-brakes (Mechanical and Hydraulic), synchro Hydraulic press-brakes, servo controlled hydraulic single cylinder press-brakes, electrically driven press-brakes.

Hydro-mechanical press-brakes American style software specifications.

Interactive 2d graphic editor for work-pieces and tools data entry.

2D graphic display of machine frame, work-piece and tools.

Manual 2D graphic identification of the best bending sequence.

Programming of the axes positions in tabular mode with automatic syntax checks, automatic calculation of the r, z and A positions and of the bending and crowning tonnage.

Windows® like user interface.

Complete off-line programming on a standard pc.

15” touch screen panel (resolution WSVGA 1366×768).

It can control up to 6+1 axis.

WDK series hybrid servo press brake adopt split double oil tanks, which use less hydraulic oil than normal hydraulic press brake.

WDK Serie CNC hydraulic press brake adopts mechanical table crowning, which is V axis controlled by CNC controller. It can automatically adjust and compensation the pressure deflection of the working table during the bending process. By using CNC table crowning, SHENCHONG hydraulic CNC press brake and ensure the bending straightness and high angle consistency.

X-axis of the back gauge adopts ball screw and linear guide, driven by digital AC servo motor, and the back gauge has retraction control function. Double linear guideway on the press brake backgauge helps to improve the bending precision. Backgauge finger Z1,Z2 axes are controlled by CNC controller, and are driven by servo motor.

Side protection ensure the operator’s working security. Rear door protection can be locked during the working process. Also customers can choose light curtain protection instead of rear door protection.

WDK Serie adopts Schneider (France) components with high quality and stable performance to ensure the electrical components using time.

CNC hybrid servo press brake machine is a universal bending equipment that is required by manufacturers who need to bend sheets.

Press various types of metal products. Hybrid servo press brake machines can process various metal materials, such as steel, aluminum, copper, titanium, etc. Hybrid press brake can bend sheet metal plate without increase the oil temperate and so it is the best option to connect with bending robot. In this case, servo hybrid press brake machine is suitable for batch production bending work.

As a hybrid servo press brake manufacturer, SHENCHONG has more than 25 years press brake machine production experience, and we have more than 20 years exporting experience. During the years of design, manufacturing, service, we provide stable high quality servo hybrid press brake and fast respond after-sale.

Since we have more than 20 years exporting experience, we can ship our machine to your country safe and quickly. We cooperate with many shipment forwarders, and we are able to provide FOB, CIF, or even door to door shipment service. No matter if this is the first time you buy machines from China, we can help to solve the shipment problems for you.

Since electric hybrid press brake can work for long time without oil temperature increasing, it is the best choice to connect with bending robot to improve the manufacturing automation level. SHENCHONG has robotic engineers to design the bending robot technical proposal and to produce the automatic robotic press brake.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.