Table of Contents

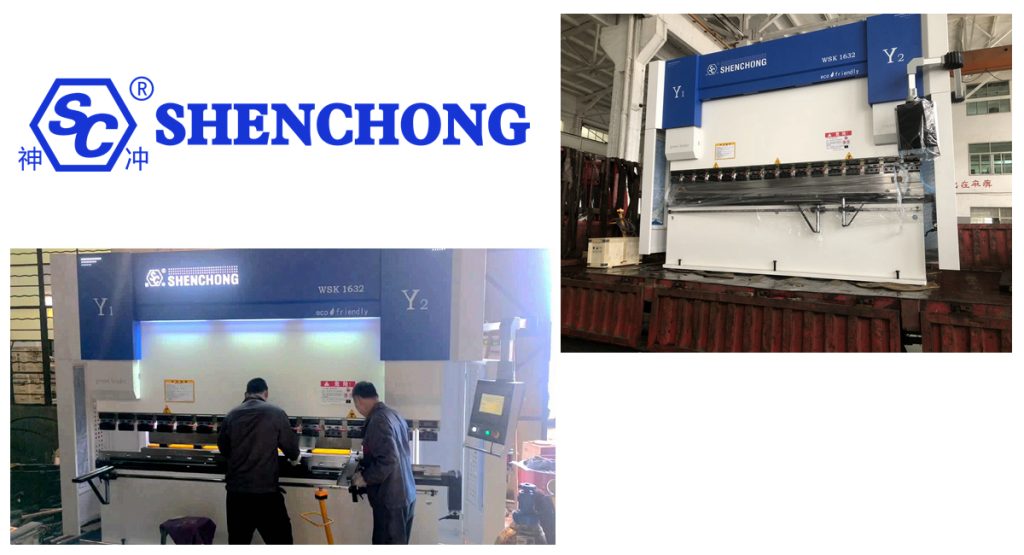

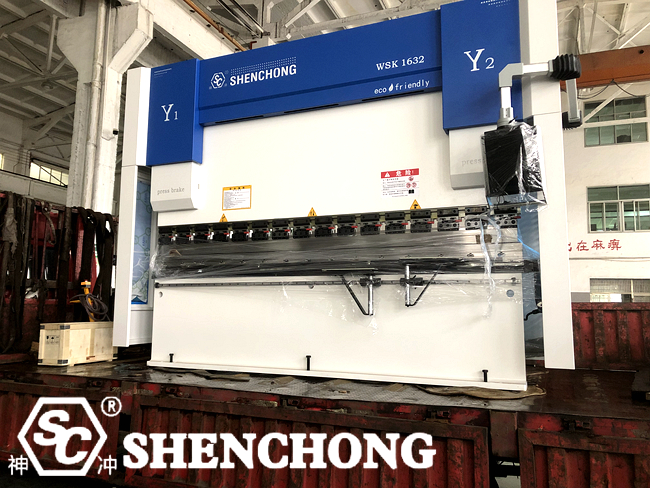

This is a energy-saving CNC press brake to Indonesia. It has now been shipped to the customer’s factory and completed installation and commissioning.

SC Energy-saving CNC press brake machine is a high-efficiency equipment for metal sheet processing. It combines CNC technology and energy-saving technology, and has the characteristics of high precision, high efficiency and low energy consumption.

SC WSK CNC press brake is usually used to process various metal sheets, perform bending, forming and other operations, and is widely used in manufacturing industries such as automobiles, aviation, home appliances and construction.

1. Indonesia CNC Press Brake Configuration

– WSK single servo pump control energy-saving series

– 160Ton 3200mm

– ESA S630

– 4+1 Axis

2. Features of energy-saving CNC press brake to Indonesia

On the basis of traditional CNC hydraulic press brakes, it optimizes energy utilization efficiency, reduces power consumption, and maintains high-precision and high-efficiency processing capabilities, so it has gradually become a mainstream equipment in modern industrial production.

High efficiency and energy saving:

Adopting advanced motor and drive system, it reduces energy consumption by intelligently adjusting motor power and reducing standby power consumption.

Precise control:

The CNC system makes the operation more precise, ensures product consistency and processing quality, and reduces waste.

Intelligent operation:

With intelligent operation interface, users can program, adjust and monitor through touch screen, which simplifies the operation process.

Environmental protection design:

In equipment design, it focuses on reducing environmental pollution such as noise and dust, which meets modern environmental protection requirements.

High production efficiency:

It reduces manual operation and setting time, can improve production efficiency and shorten production cycle.

Strong adaptability:

It can process metal sheets of different thicknesses and types, with strong adaptability to meet different production needs.

3. Press brake energy-saving technology

Servo motor technology:

Servo motors are used instead of traditional motors to automatically adjust power output according to load, thereby effectively reducing power consumption.

Intelligent power management:

Optimize power use through CNC systems and intelligent software to reduce standby power consumption and no-load consumption.

Optimize hydraulic system:

Optimize the hydraulic system so that the hydraulic system can operate efficiently while reducing fuel consumption and energy loss.

These features make the Indonesia energy-saving CNC press brake WSK not only reduce energy consumption during the production process, but also improve production efficiency and processing accuracy.

If you have specific needs (such as sheet specifications and bending requirements, etc.), we can recommend suitable equipment configurations and solutions for you.