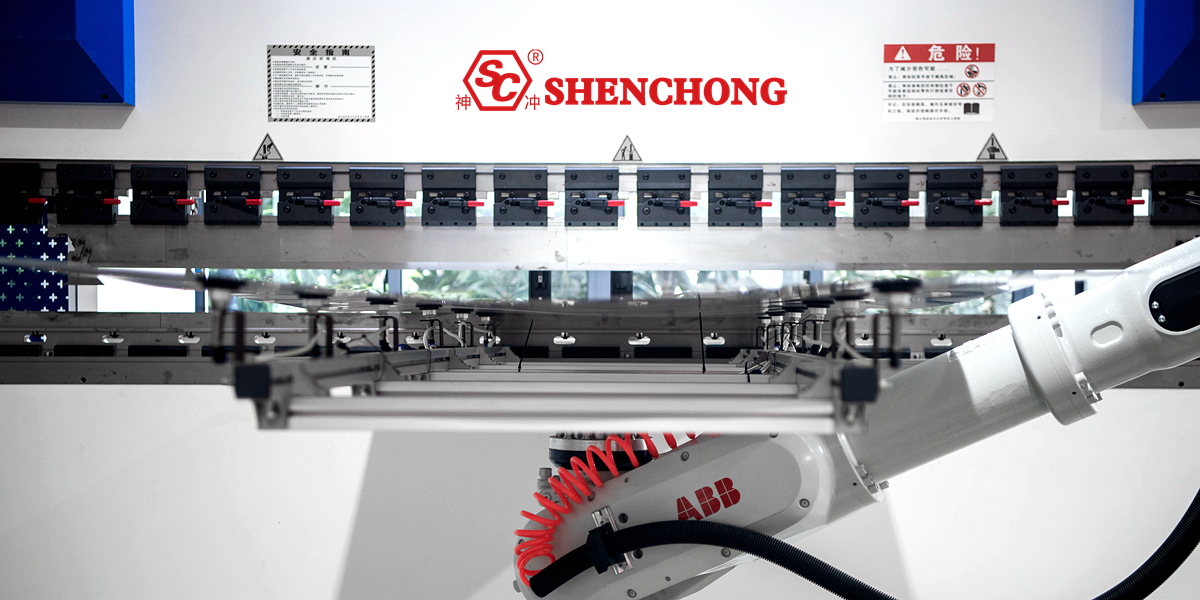

In the bending process of large air-conditioning metal panels, the use of SC DLSD10 bending follower devices can significantly improve processing accuracy and production efficiency.

SC Bending Follower For Air Conditioning Panel Bending Model

- Brand: SC SHENCHONG

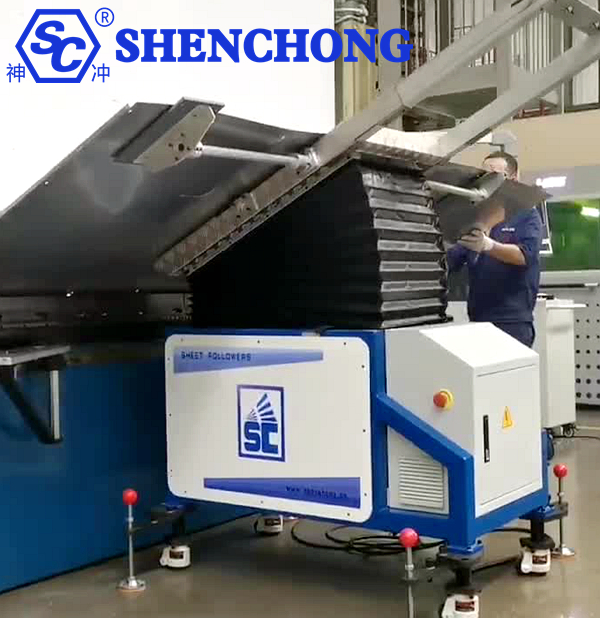

- Model: DLSD10 press brake bending follower

- Lifting Weight: 100KG

- Turning Over Angle: 75 degree

- Turning Over Speed: 85 degree/s

SC DLSD10 sheet bending follower for large air-conditioning metal panels processing

Air-conditioning equipment mainly includes central air-conditioning, purification air-conditioning, industrial refrigeration, and commercial air-conditioning. When manufacturing and processing the metal shell of such air-conditioning equipment, we can use the SC bending follower device to assist the CNC press brake machine in processing. Thereby, reduce the work intensity and improving the bending quality.

The bending accuracy of the air conditioner metal panel directly affects the appearance and function of the product, such as the assembly accuracy and sealing requirements of other components. The bending follower can monitor and adjust the bending parameters in real time to ensure that the quality of each panel meets the standards.

Especially for some large air-conditioning equipment, their metal cover panels are relatively large, and it is difficult for one or two workers to complete the bending work. At this time, the use of the sheet bending followers can save time and effort, greatly improve work efficiency and ensure production safety.

Why you need SC sheet metal bending follower?

In the bending of large metal panels, especially for long and large panels, deformation or errors are prone to occur during bending. Traditional manual bending machines or CNC bending machines without follower devices may not be able to accurately control the bending angle, especially when the plate is long, the center and edge of the plate may produce inconsistent bending effects due to uneven pressure.

For factories that mass-produce air-conditioning panels, the use of sc bending follower devices can significantly improve production efficiency, reduce the time for manual adjustment, and avoid product failures due to manual operation errors.

Bending of large-size panels:

For large air-conditioning metal panels (especially those with large length and width), if there is no follower, there will be uneven pressure distribution during the bending process, resulting in inaccurate bending in local areas. After using the follower, the system can adjust the pressure and angle in real time throughout the bending process, so that even large-size panels can maintain a uniform bending effect.

- Long plate bending: When processing long plates, the follower ensures that the bending effect of the middle part is consistent with that of the two ends, avoiding the problem of excessive or insufficient bending in the middle part.

- Uniform bending over a large area: Whether it is a large panel or a small panel, the follower device can adjust the bending machine according to real-time data to ensure consistent bending in all parts.

Optimize production process:

- The SC DLSD10 bending followerplays an important role in optimizing the production process, ensuring stability and accuracy during the bending process, thereby reducing defective products and improving the repeatability of the process.

In the bending process of large air-conditioning metal panels, SC DLSD10 bending follower can effectively improve processing accuracy, production efficiency, process stability, and reduce the risk of manual intervention and operating errors.

By adjusting the pressure, angle and other parameters of the bending machine in real time, the follower ensures that each panel can meet high-standard design requirements, especially when processing large-size, complex-shaped or different-material panels.