Table of Contents

SC 1500X3000MM CNC Gantry Four-Side Grooving Machine is a device specially used for metal sheet processing. It is usually used to accurately slot the four edges of the sheet. This model uses CNC technology to achieve high-precision and high-efficiency processing. It is commonly used in manufacturing, aerospace, automotive, mold and machinery industries.

1. Working principle of CNC gantry four-side grooving machine

Its working principle is usually to control the tool on the gantry structure through the CNC system to groove the four sides of the metal sheet according to the predetermined path. The CNC gantry four-side groover controls the movement of the tool through the CNC system to achieve precise processing of the four sides of the metal sheet.

The gantry structure is usually composed of a beam, a column, a bed, a workbench, etc. The tool can move in the three axes of X, Y, and Z to perform the grooving process. Unlike traditional manually operated machine tools, the CNC system can automatically perform tasks according to programming instructions, reduce human intervention, and ensure high precision and efficiency of processing. The advantage of this type of machine tool is its high processing accuracy, which can ensure that the processed metal sheets are of consistent size and smooth surface, and can greatly improve production efficiency.

2. Structural composition

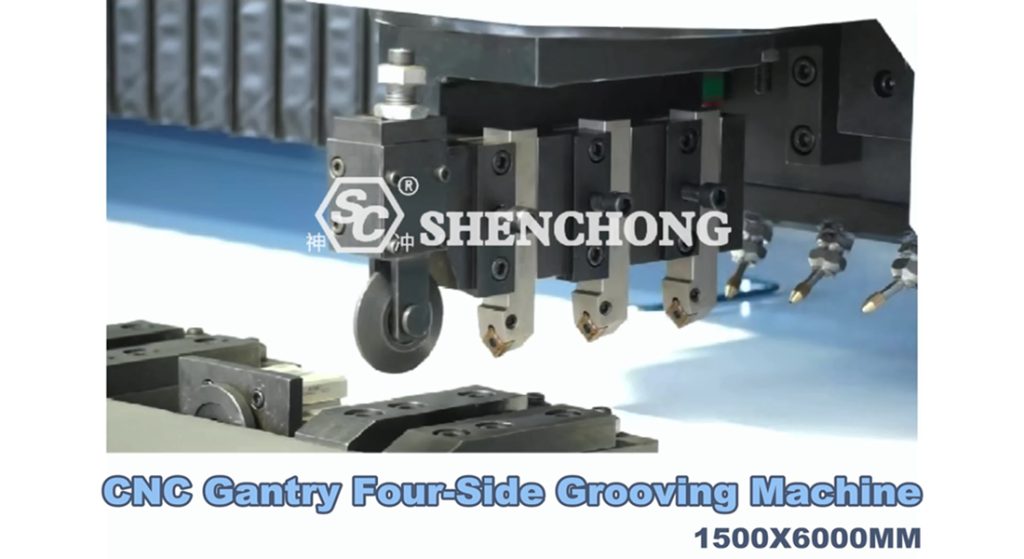

Gantry structure:

Gantry structure makes the equipment more stable, especially suitable for processing large-sized metal plates. Its basic structure is a fixed bed and a horizontally movable workbench, which can ensure the accuracy and consistency during the processing.

CNC system:

This type of equipment is equipped with an advanced CNC system. Through programming and digital control systems to accurately control the movement of the tool, it can achieve automated and refined operations.

Drive system:

SC 1500X3000MM gantry four-side CNC grooving machines are usually equipped with efficient servo motors and ball screw drive systems, which can ensure the precise movement of the tool during the processing, reduce errors, and improve processing speed and efficiency.

3. 1500X3000MM CNC gantry four-side grooving machine features

- Four-side v grooving function: It can precisely process the four sides of the plate at the same time, solving the problem that the grooving of traditional gantry machines requires manual steering.

- CNC system: Equipped with advanced CNC system, it can accurately control the processing path and provide higher processing accuracy.

- Gantry structure: It provides a stable processing platform to ensure stability and accuracy during the processing.

- High efficiency: It is suitable for mass production and can significantly improve processing efficiency.

1500X6000MM CNC gantry four-side V grooving machine is a high-precision, high-efficiency large-scale CNC machine tool suitable for a variety of complex processing tasks. Its large-size processing range and multifunctional design make it an indispensable and important equipment in the fields of mold manufacturing, aerospace, and automotive industries. Although the investment cost is high, its high-precision and high-efficiency processing capabilities can significantly improve productivity, especially for industrial applications that require large-scale, high-precision processing.