Profile bending machine is a specialized and efficient processing equipment used for bending various shaped materials such as angle steel, channel steel, I-beams, flat steel, square pipes, and round pipes. It can complete the end pre bending of various profiles, roll circular and curved workpieces, and is widely used in industries such as aerospace, petrochemical, hydropower, shipbuilding, automotive manufacturing, mechanical manufacturing, and steel structure construction.

Profile bending machine has a curved downward adjustment structure, with the upper roller shaft fixed and the two lower roller shafts moving up and down in an arc around a central axis relative to the upper roller shaft. Its main function is to pre bend the end of the profile and make it bend and deform. At the same time, the two lower roller shafts are also the main transmission shaft, driven by a hydraulic motor, to roll and shape the bent and deformed profile. To prevent distortion and deformation of profiles during the bending process and improve the bending accuracy of profiles, two rollers and rollers are added, which can move vertically up and down to adapt to different specifications and bending radii of profiles.

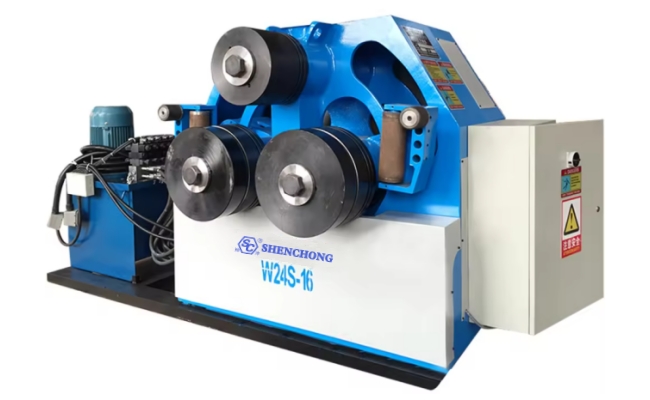

SC profile roll bending machine is an important metal processing equipment, widely used in various fields. The profile bending machine can handle different types and sizes of profiles, including angle steel, channel steel, I-beam, T-beam, etc., and has strong adaptability.

|

Model&spec. |

W24S-6 |

W24S-16 |

W24S-30 |

W24S-45 |

W24S-75 |

W24S-100 |

W24S-140 |

|

|

Max bending modulus of section (cm3) |

6 |

16 |

30 |

45 |

75 |

100 |

140 |

|

|

Bending speed(m/min) |

5.5 |

5.5 |

5.5 |

5.5 |

5 |

5 |

5 |

|

|

yield limit of material (MPa) |

245 |

245 |

245 |

245 |

245 |

245 |

245 |

|

|

inward bending of angle steel |

The max cross section (mm) |

50×5 |

80×8 |

90×10 |

100×10 |

120×12 |

140×16 |

150×16 |

|

The min bending diameter (mm) |

800 |

1000 |

1200 |

1500 |

2000 |

2500 |

2400 |

|

|

The min cross section (mm) |

20×3 |

30×3 |

35×3 |

36×5 |

38×4 |

40×5 |

50×5 |

|

|

The min bending diameter (mm) |

400 |

550 |

560 |

600 |

600 |

720 |

1000 |

|

|

outward bending of angle steel |

The max cross section (mm) |

50×5 |

80×8 |

90×10 |

100×10 |

120×12 |

140×16 |

150×16 |

|

The min bending diameter (mm) |

800 |

1000 |

1100 |

1300 |

1600 |

1800 |

2200 |

|

|

The min cross section (mm) |

20×3 |

30×3 |

35×3 |

36×5 |

38×4 |

45×5 |

50×5 |

|

|

The min bending diameter (mm) |

400 |

550 |

500 |

600 |

700 |

760 |

400 |

|

|

outward bending of channel steel |

channel steel model |

8 |

12 |

16 |

20 |

25 |

28 |

30 |

|

The min bending diameter (mm) |

600 |

800 |

800 |

1000 |

1100 |

1100 |

1200 |

|

|

inward bending of channel steel |

channel steel model |

8 |

12 |

16 |

20 |

25 |

28 |

30 |

|

The min bending radius (mm) |

700 |

900 |

1000 |

1150 |

1600 |

1700 |

1700 |

|

|

plane bending of flat steel |

The max cross section (mm) |

100×18 |

150×25 |

180×25 |

200×30 |

220×40 |

250×40 |

280×50 |

|

The min bending diameter (mm) |

600 |

700 |

800 |

900 |

1000 |

1200 |

1300 |

|

|

vertical bending of flat steel |

The max cross section (mm) |

50×12 |

75×16 |

90×20 |

100×25 |

110×40 |

120×40 |

150×40 |

|

The min bending diameter (mm) |

500 |

760 |

800 |

1000 |

1100 |

1300 |

1500 |

|

|

bending of round pipe |

The max cross section (mm) |

42×4 |

76×4.5 |

89×5 |

89×8 |

114×5 |

159×5 |

168×6 |

|

The min bending diameter (mm) |

500 |

750 |

900 |

900 |

1200 |

2000 |

2000 |

|

|

bending of round bar |

The max cross section (mm) |

38 |

52 |

62 |

75 |

85 |

90 |

100 |

|

The min bending diameter (mm) |

450 |

600 |

600 |

800 |

100 |

1100 |

1200 |

|

|

bending of square pipe |

The max cross section (mm) |

45×3 |

60×4 |

70×4 |

80×6 |

90×8 |

100×10 |

125×10 |

|

The min bending diameter (mm) |

750 |

900 |

1000 |

1200 |

1600 |

2000 |

2500 |

|

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.