Fiber laser cleaning machine is a powerful tool that uses a focused beam of light to clean and remove surface contamination. It uses laser technology to heat the rust, causing it to break down and flake off. It is an excellent alternative to traditional rust removal methods such as sandblasting and chemical treatments because it is more efficient and produces less waste. It is also more precise and can be used to target specific areas of rust without damaging the surrounding metal. With their advanced features and capabilities, fiber laser cleaning machines are quickly becoming the first choice for many cleaning tasks.

The fiber laser cleaning machine has a good cleaning effect on iron, carbon steel plate, stainless steel plate, mold steel gear, aluminum plate, paint layer, and other materials. It can be used to clean the oxide layer, surface paint removal treatment, clean surface oil, stains, and dirt, clean rubber mold residues, and meet the equipment cleaning requirements in the fields of the shipbuilding industry, auto parts, rubber molds, machine tools, and environmental protection industries.

The handheld laser cleaning machine is a portable device that uses laser technology to remove contaminants, rust, paint, and other unwanted substances from surfaces. The laser beam is generated by a laser generator and directed through an in-line cable to a handheld device that focuses the beam onto the surface to be cleaned.

Model | SCLC-1000 | SCLC-1500 | SCLC-2000 | SCLC-3000 |

Laser Power | 1000W | 1500W | 2000W | 3000W |

Laser Type | Fiber Laser | |||

Laser Generator | JPT / Raycus / Reci / IPG / Max | |||

Pulse Formation | Q-Switched (Quality factor) | |||

Cleaning Efficiency | 12㎡/h | |||

Scanning Width | 10-80mm | |||

Expected Focal Distance | 160mm | |||

Fiber Cable Length | 10m | |||

Cooling Type | Water cooling | |||

Using well-known brand laser generators (Raycus / JPT / Reci / Max / IPG), a high photoelectric conversion rate ensures the laser power and makes the welding effect better.

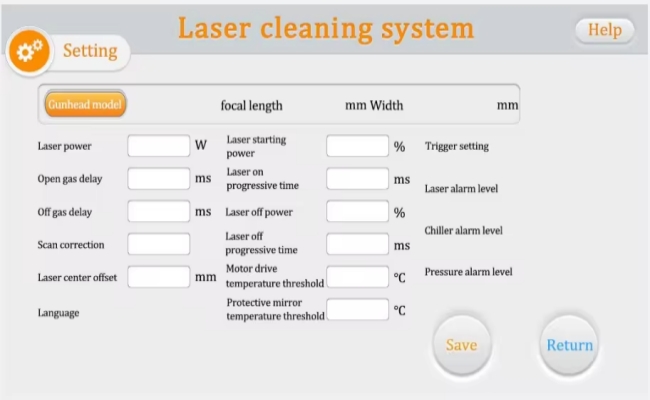

SC provides high-performance, intuitive, and easy-to-use operating systems. It expands the tolerance range and weld width of machined parts and provides better weld formation results. The operating system supports Chinese, English, Korean, Russian, Vietnamese, and other languages.

Use very flexible cables, arrange them rigorously, and route them in an orderly manner.

Safer, more durable, easy to troubleshoot.

Schneider’s high-end brand of electrical components is not easily damaged, with guaranteed quality.

Laser welding is a new welding method that is widely used in the automotive industry, metal processing industry, ship and aircraft manufacturing, furniture and kitchenware processing, electronic product processing, metal parts repair and other precision processing industries. It is mainly used for thin-walled materials and precision parts. welding. Spot welding, butt welding, lap welding and sealing welding can be realized. Titanium alloy, galvanized sheet, aluminum, and copper laser welding machines can all be accurately welded.

Fiber laser cleaning machine is a new generation of high-tech surface cleaning products. It can solve many problems that traditional cleaning cannot solve, including metal rust, metal particles, dust, etc.

Equipment Mode | SC-1000W | SC-1500W | SC -2000W | SC-3000W |

Laser Power | 1000W | 1500W | 2000W | 3000W |

Laser Wavelength | 1064~1080nm | |||

Pulse Frequency | 5000~10000Hz | |||

Cooling Method | Water cooling | |||

Dimension(mm3) | 1050*620*1360 | 1050*620*1360 | 1050*620*1360 | 1300*850*1450 |

Total Weight | 200KG | 260KG | 280KG | 310KG |

Scan Width | 10-50mm/10-67mm/10-80mm optional | |||

Working Temperature | -30~40 ℃ | |||

Laser Power Brand | Raycus、MAX、BWT (optional) | |||

Laser rust removal machine is a device that uses laser technology to remove rust from metal surfaces. Compared to traditional mechanical friction rust removal methods, laser rust removal machines have advantages such as fast speed, high efficiency, simple operation, and no loss, and are increasingly favored by industrial enterprises.

The working principle of fiber laser cleaning machine can be simply summarized into three steps:

Portable fiber laser cleaning machine is suitable for rust removal and cleaning of various metal surfaces, especially for cleaning oil, dirt, and coatings on metal surfaces with good cleaning effects. Laser rust removal machines can also be applied in rust removal and cleaning work in fields such as automotive manufacturing, aerospace, rail transit, and railway maintenance.

In short, portable fiber laser cleaning machine is an efficient, environmentally friendly, and energy-saving rust removal tool, which will play an increasingly important role in future industrial applications.

Common laser cleaning machines include continuous laser cleaning machines and pulse laser cleaning machines, and different cleaning requirements require different types of cleaning equipment. Simply put, pulse laser cleaning machines do not cause damage to the components and are suitable for products with high cleaning requirements;

Power is one of the key parameters of laser cleaning machines, which directly affects the cleaning effect. Simply put, the higher the power of the laser cleaning machine, the faster the cleaning speed. Of course, it is also necessary to consider the parameter settings during actual cleaning.

When choosing a laser cleaning machine. The stability of equipment operation is a very important reference factor, which directly affects the quality and efficiency of cleaning. If the equipment is unstable, it may cause damage to the components.

When using a laser cleaning machine, factors such as the convenience of operation and the convenience of equipment maintenance in the later stage should be considered.

SC is a professional sheet metal forming machine manufacturer, and we provide all solutions for clients to solve the sheet metal processing problems. Welcome to contact with us if you need any machines in metal cutting or forming.

The advantages of portable fiber laser cleaning machine mainly include high efficiency, non-contact cleaning, selective cleaning, environmental protection, and wide applicability. It can quickly remove rust, avoid physical wear, accurately locate and remove rust, and does not use chemical reagents, suitable for various metals and complex shaped objects. In addition, the laser rust removal machine can be integrated with CNC machine tools or robots to implement remote control rust removal, forming a product assembly line operation, intelligent operation, and without damage to the metal substrate, with good stability and low maintenance costs.

However, the disadvantages of laser rust removal machines include high cost, high operational requirements, high energy consumption, safety hazards, and limited usage scenarios. The cost of procurement and maintenance is high, requiring specialized trained operators who may consume more electricity during operation. Laser may cause harm to the operator’s eyes and skin, and due to the size of the equipment and the required power supply, it may not be suitable for all on-site environments.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.