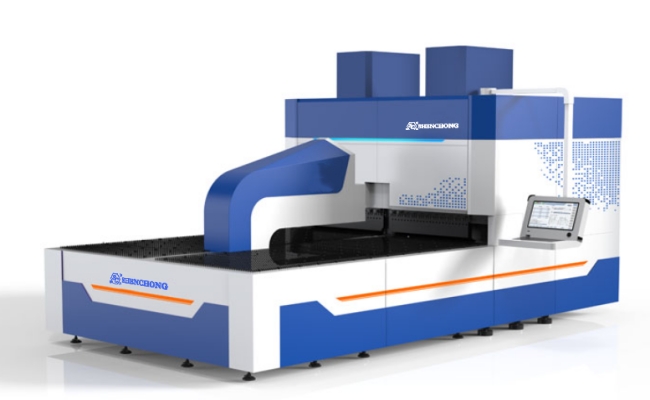

As the leading panel bender manufacturer in China, SC SHENCHONG always provide the best automatic bending solutions to customers around the world. Panel bender is a commonly used bending machine in the production of metal sheet metal workpieces. It refers to the process of fixing the metal sheet metal on a mechanical bending machine by setting bending curves on the sheet metal, and then applying pressure on the bending line according to the required bending angle to achieve the processing of the metal sheet metal.

It can be widely used in the fields of steel cabinet shells, kitchen utensils, furniture, ventilation, refrigeration, purification, door industry, decoration, elevators, and other related metal forming fields, suitable for bending different types of workpieces.

Panel bender is an effective metal forming machine to bend thin materials. The automatic panel bending center focuses on solving various complex sheet metal and bending problems in metal forming. In one process, it is possible to rapidly complete a complex part that requires very accurate radius forming, hemming, or offset bends. Compared with CNC press brake, the cnc panel bender is more efficient and labor-saving when bend the thin sheet plate.

SC SHENCHONG panel bender plate thickness range:

Aluminum plate: up to 3.5mm

Carbon steel: up to 2mm

Stainless steel: up to 1.5mm

|

Item |

Unit |

Panel Bender Model |

||

|

SC-1400/ SC-S1400 |

SC-S2000 |

SC-S2500 |

||

|

Feeding Method |

|

Vacuum Suction Cup/ Pressure Arm |

Pressure Arm |

Pressure Arm |

|

Bending Length |

mm |

1400 |

2000 |

2500 |

|

Max. Bending Height |

mm |

170 |

170 |

170 |

|

Min. Bending Height |

mm |

4 |

4 |

4 |

|

Minimum Molding Size of 4 Sides |

mm |

200×120/110×140 |

110×140 |

110×140 |

|

Min. Molding Size of Single Sides |

mm |

120/110 |

110 |

110 |

|

Min. Arc Radius |

mm |

1.2 |

1.2 |

1.2 |

|

Min. Continuous Bending Speed |

s |

0.2 |

0.2 |

0.2 |

|

Bending Angle |

degree |

0-180 |

0-180 |

0-180 |

|

Number of Control Axes |

|

9/10 |

10 |

10 |

|

Max. Feeding Speed |

m/min |

50/120 |

120 |

120 |

|

Overall Dimensions |

mm |

4000x3000x2500 |

5800x3100x2350 |

6000x3100x2350 |

|

Weight |

T |

10 |

18 |

22 |

|

Max.Power |

KW |

22 |

25 |

32 |

|

Average Operating Power |

KW |

3.5 |

3.5 |

4.5 |

|

Workbench Structure |

|

Brush and Universal Ball |

Brush and Universal Ball |

Brush and Universal Ball |

The fully automatic servo bending center is an efficient and intelligent sheet metal processing equipment, mainly used for precise bending operations on sheet metal. It combines servo motors and CNC technology to achieve a fully automated processing process.

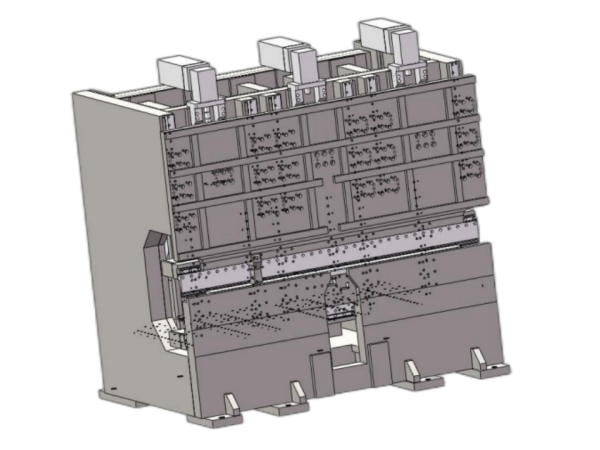

Servo flexible bending center frame. The frame adopts high-strength welding structure, the main structure is stable with a long service life.

Heat treatment to remove internal stress, strong rigidity, heavy tonnage,ensuring long-term stability of the machine accuracy, and improving the bending accuracy, reliability and durability of the bending center.

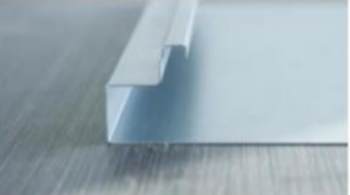

Panel bender is suitable to bend the narrow side of thin plates.

At present, there are two main feeding methods for bending centers. One is suction cup feeding, which uses a negative pressure pump to vacuum and adsorb the sheet metal. This requires a smooth and flat surface of the sheet metal to ensure that the workpiece will not be misaligned during feeding and rotation.

Another type is pressure arm feeding, which clamps the workpiece with two upper and lower claws. This method does not require a smooth and flat surface of the sheet metal, with pores, surface indentations, or more complex rows of workpieces. As long as there is a place for clamping, it is sufficient, but the suction cup type cannot be used. The pressure claw of the pressure arm is generally small and can adapt to smaller sized workpieces.

The suction cup type equipment has significant differences in structure and feeding principle compared to the pressure arm type, and also has significant differences in price. If the suction cup type equipment can meet the demand, then choosing a suction cup type bending center may also be a good choice.

It’s because when our bottom folding knife folds the last edge upwards, the slope of the pressure knife will collide with our workpiece, so our last edge cannot be folded to 90 degrees. In this case, it is necessary to customize the upper pressing knife according to the process of the workpiece, and appropriately cut off the collision part, so as to achieve bending.

There are many types of customization for cutting tools, mainly based on the specific bending process of the workpiece. Cutting tools are independently developed and produced, so they can flexibly provide customized services for customers.

SC SHENCHONG panel bender price is depends on the machine model and the additional axes. Panel bender is an intelligent automatic bending machine, which can be add a lot of customized functions, and so the price range is large. Not only the single unit panel bender, but also SC SHENCHONG can produce the automatic panel bender production line. We are the professional panel bender machine manufacturer and we will provide you the most reasonable price.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.