SC SHENCHONG NC press brake is the hydraulic twisted shaft synchronous press brake with NC controller, which can shows the Y axis and X axis position.

Brand: SC SHENCHONG

Model: WC67K NC Press Brake Machine

CNC Controller: ESTUN E21

Price Range: $15000-$30000/Set

After Sale: 3 Years

Lead Time: 25-45 Working Day

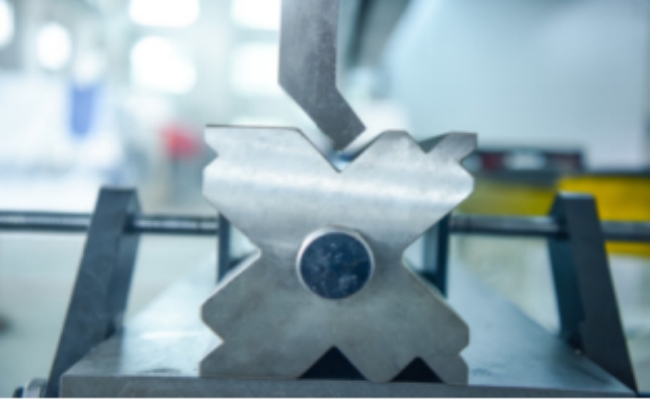

Twisted shaft synchronous hydraulic press brake is a machine used for metal sheet metal processing, which is based on the rotation of the torsion axis to achieve the bending process of the sheet metal. The following analysis will be conducted from the aspects of product structure, working principle, advantages, and usage scenarios.

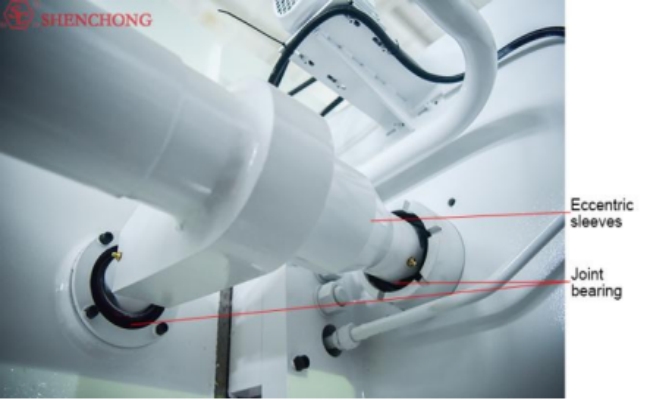

Firstly, the machine structure of the torsion shaft press brake machine mainly consists of a frame, torsion shaft, motor, transmission system, positioning device, and fixture. The rack is the supporting frame of the entire equipment, and the torsion shaft is the core component. The motor and transmission system provide power, and the positioning device and fixture are used to fix and clamp the board, respectively.

Secondly, in terms of working principle, the torsion axis NC hydraulic press brake machine achieves the bending process of the sheet metal through the rotation of the torsion axis. A torsion shaft generally consists of two curved shafts, one of which is fixed with a fixture, and the sheet metal is fixed on the fixture. When the motor drives the transmission system to work, the torsion shaft starts to rotate, and the fixture on the shaft will also rotate together, so that the sheet metal is subjected to centrifugal force during rotation, achieving the bending of the sheet metal.

SC SHENCHONG NC press brake with ESTUN E21 controller models from 40 Tons 2000mm to 300 Tons 3200mm. If clients want to buy press brake model over 300 tons, we recommend them to choose CNC press brake, which has different machine structure and have better bending results.

|

Model |

Nominal Pressure(kN) |

Length of Table (mm) |

Distance Between Housings (mm) |

Throat Depth (mm) |

Stroke (mm) |

Open Height (mm) |

Main Motor (Kw) |

Overall Dimensions LxWxH (mm) |

Height (Ton) |

|

63/2500 |

630 |

2500 |

2000 |

250 |

105 |

345 |

5.5 |

2600x1350x2180 |

4.5 |

|

100/3200 |

1000 |

3200 |

2600 |

320 |

145 |

395 |

7.5 |

3300x1500x2355 |

7.2 |

|

125/3200 |

1250 |

3200 |

2600 |

320 |

145 |

405 |

7.5 |

3300x1570x2470 |

8.2 |

|

125/4000 |

1250 |

4000 |

3200 |

400 |

145 |

405 |

7.5 |

4100x1570x2520 |

9.2 |

|

125/5000 |

1250 |

5000 |

3800 |

320 |

145 |

405 |

7.5 |

5100x1570x2700 |

11.5 |

|

125/6000 |

1250 |

6000 |

4500 |

320 |

145 |

405 |

7.5 |

6100x1570x2800 |

14.5 |

|

160/3200 |

1600 |

3200 |

2500 |

320 |

145 |

415 |

11 |

3300x1600x2525 |

11 |

|

160/4000 |

1600 |

4000 |

3000 |

320 |

145 |

415 |

11 |

4100x1600x2595 |

12.8 |

|

160/5000 |

1600 |

5000 |

3800 |

320 |

145 |

415 |

11 |

5100x1600x2900 |

16.5 |

|

160/6000 |

1600 |

6000 |

4500 |

320 |

145 |

415 |

11 |

6100x1600x3000 |

18.8 |

|

200/3200 |

2000 |

3200 |

2500 |

320 |

145 |

420 |

11 |

3300x1800x2685 |

12.5 |

|

200/4000 |

2000 |

4000 |

3000 |

320 |

145 |

420 |

11 |

4100x1800x2775 |

14.2 |

|

200/5000 |

2000 |

5000 |

3800 |

320 |

145 |

420 |

11 |

5100x1800x3050 |

19 |

|

200/6000 |

2000 |

6000 |

4500 |

320 |

145 |

420 |

11 |

6100x1800x3150 |

22 |

|

200/3200 |

2500 |

3200 |

2200 |

400 |

195 |

430 |

15 |

3300x1890x2875 |

14 |

|

250/4000 |

2500 |

4000 |

3000 |

400 |

195 |

435 |

15 |

4100x1890x2920 |

16 |

|

250/5000 |

2500 |

5000 |

3800 |

400 |

195 |

435 |

15 |

5100x1890x3200 |

22 |

|

250/6000 |

2500 |

6000 |

4500 |

400 |

195 |

435 |

15 |

6100x1890x3320 |

26 |

|

300/3200 |

3000 |

3200 |

2200 |

400 |

245 |

490 |

22 |

3300x2150x3160 |

18 |

|

300/4000 |

3000 |

4000 |

2800 |

400 |

245 |

490 |

22 |

4100x2150x3200 |

20.5 |

|

300/5000 |

3000 |

5000 |

3800 |

400 |

245 |

490 |

22 |

5100x2150x3350 |

25 |

|

300/6000 |

3000 |

6000 |

4500 |

400 |

245 |

490 |

22 |

6100x2150x3500 |

29 |

|

400/4000 |

4000 |

4000 |

2800 |

400 |

245 |

495 |

30 |

4100x2310x3500 |

28 |

|

400/5000 |

4000 |

5000 |

3800 |

400 |

245 |

495 |

30 |

5100x2310x3620 |

33 |

|

400/6000 |

4000 |

6000 |

4500 |

400 |

245 |

495 |

30 |

6100x2310x3750 |

38 |

|

500/4000 |

5000 |

4000 |

2800 |

500 |

245 |

505 |

37 |

4100x2450x3650 |

34 |

Eston E21 CNC system

Y-axis and X-axis system control adjustment

Delta frequency converter controls X-axis and Y-axis positioning

Using HIWIN ball screw and light strip to ensure an accuracy of 0.05mm.

Front bracket support

United States First Valve and First Pump

German EMB oil pipe joint

German Siemens main motor

Schneider Electric, France

Hydraulic and electrical overload protection

Standard upper and lower press brake tools

High definition LCD display screen, available in both Chinese and English languages, displaying programming parameters on one page for faster and more convenient programming.

Y-axis intelligent positioning, can also be manually adjusted as needed, removing mechanical hand cranked positioning devices.

Equipped with built-in pressure holding time and unloading delay setting functions, the operation is more convenient, without the need for time relays, reducing costs.

With one click parameter backup and recovery function, parameters can be restored at any time as needed, reducing maintenance costs.

Supporting multi-step programming, complex workpieces can be processed in one go, improving production efficiency and machining accuracy.

Store 40 programs with 25 steps per program.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.