Table of Contents

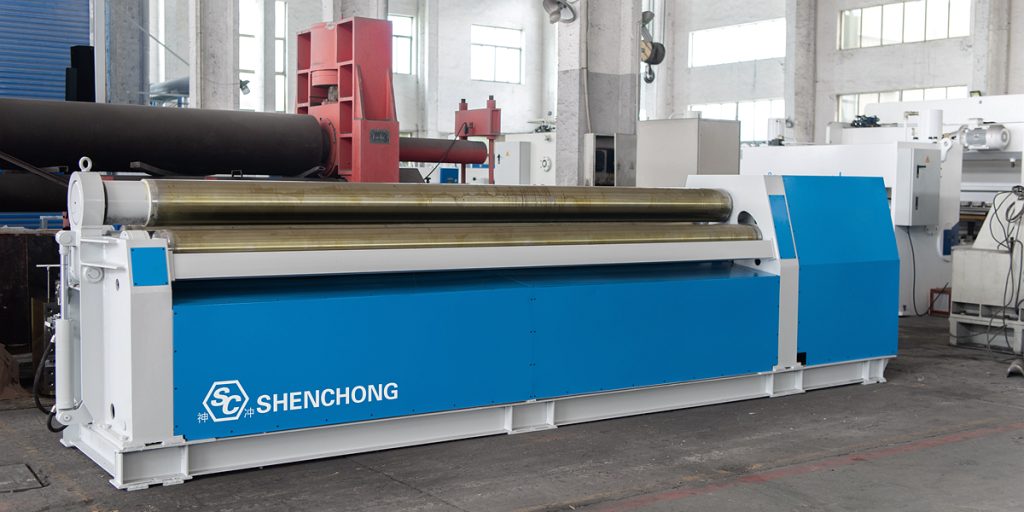

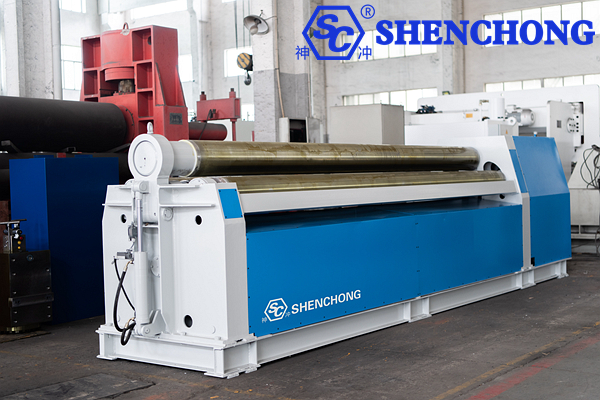

Ireland Four-roller Plate Rolling Machine W12NC-6X4000MM is a high-precision, high-efficiency CNC hydraulic plate rolling equipment, suitable for rolling cylindrical, arc-shaped and conical workpieces in industries such as petroleum, chemical, boiler, shipbuilding, and steel structure.

SC Machinery four-roller plate rolling machine has the characteristics of high degree of automation, convenient operation, and excellent forming quality. The following is a detailed introduction of the equipment.

1. Main technical parameters of Ireland plate rolling machine

Item | Parameter description |

Model | W12NC-6×4000 |

Maximum plate thickness | 6 mm (Q235 material) |

Maximum plate width | 4000 mm |

Upper roller diameter | Approx. Ø270 mm |

Lower roller diameter | Approx. Ø210 mm |

Side roller diameter | Approx. Ø210 mm |

Rolling speed | Approx. 4 m/min |

Main motor power | Approx. 5.5 kW |

Minimum roll diameter | Approx. 1.1 times the upper roller diameter |

Control system | CNC system |

Operation mode | Centralized control, equipped with a mobile operating table |

2. Equipment features of Ireland four-roller plate rolling machine W12NC-6X4000MM

- Complete pre-bending and rolling in one feeding: no need to turn around, saving time and improving efficiency.

- High-precision forming: the remaining straight edge of the pre-bending is less than or equal to 1.5 times the plate thickness, meeting the requirements of automated welding.

- Hydraulic transmission system: the lower roller and side roller lifting adopt hydraulic transmission, with smooth movement and precise control.

- Inverted side roller cylinder design: reduces the height of the machine body, facilitates ground installation, and reduces infrastructure construction costs.

- Multi-functional rolling capacity: can roll a variety of shapes such as round, arc, oval, square, triangle, etc.

- Optional automatic lifting rack and external bracket: auxiliary rolling, reducing labor, improving product quality and work efficiency.

- Optional conical rolling device: meets the user’s needs for rolling conical workpieces, easy to operate, low cost, and good rolling quality.

3. Applicable materials

- Carbon steel plate (Q235/Q345)

- Stainless steel plate (SUS304, 316)

- Aluminum plate, copper plate and other non-ferrous metals (roller surface hardness needs to be customized)

4. Typical application areas of plate rolling machines

Industry | Application examples |

Building steel structure | Cylindrical shell, chimney pipe section, curtain wall decorative steel plate forming |

Pressure vessel manufacturing | Gas storage tank cylinder, heat exchanger shell, tower section rolling |

Shipbuilding and offshore engineering | Oil tank wall, shell arc parts, hull frame parts |

Pipeline engineering | Water pipeline, air duct, ventilator, steel casing |

Machinery manufacturing and metal processing | Drum, head, roller shell, cylindrical components, etc. |

SC Ireland four-roller plate rolling machine W12NC-6×4000MM is mainly used for high-precision metal plate rolling, and is widely used in construction, shipbuilding, pressure vessels, steel structures and other industries. It adopts advanced hydraulic and CNC technology to ensure efficient and accurate rolling effects. Welcome to inquire!