IPG and Raycus are two laser brands widely used in laser cutting machines. They each have their own advantages and different characteristics. Below, SC Machinery professional laser cutting machine supplier, will introduce these two lasers in detail and IPG VS Raycus comparison.

Table of Contents

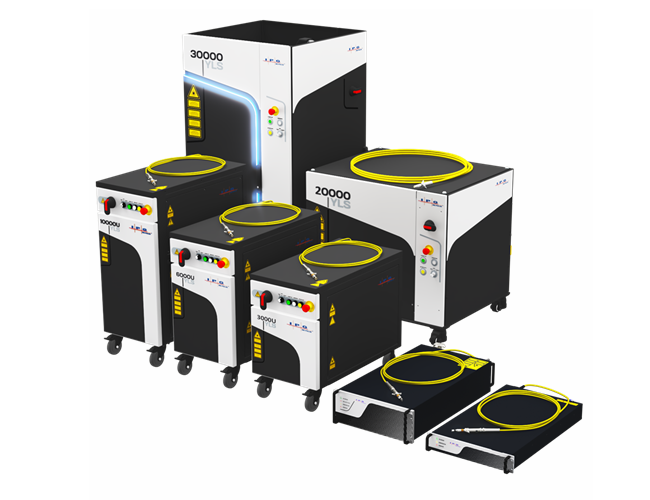

1. Introduction to IPG Lasers

IPG lasers are one of the pioneers of fiber laser technology, and their technology and products occupy an important position in the laser cutting industry. IPG lasers have excellent performance in many fields, especially in industrial laser cutting machines.

1) Technical advantages

IPG fiber laser uses a fiber gain medium, which has higher efficiency and longer service life than traditional CO2 lasers. Fiber lasers have a high electro-optical conversion efficiency (>30%), which makes IPG lasers excellent in power and energy consumption.

2) Output power

IPG offers a wide range of fiber lasers, ranging from 500W to 20kW, to meet different application requirements. Especially in high-power laser applications, IPG lasers are very competitive and can handle thick plate cutting and efficient welding.

3) Cutting accuracy and speed

IPG lasers have good output beam quality, good focusing performance, and high cutting accuracy.

In high-power cutting applications, IPG lasers can not only provide fast cutting, but also maintain good incision quality, which is suitable for cutting tasks with high precision requirements.

4) High reliability and stability

IPG fiber lasers have excellent thermal management capabilities, which enables the laser to maintain stable operation under long-term high-load operation. The lasers generally have a long life and a low equipment failure rate, so they can maintain efficient and continuous operation in industrial production.

5) Low maintenance cost

Since fiber lasers do not require laser gas and gas delivery systems, they reduce gas dependence and complex maintenance work. They have low maintenance costs and relatively simple operation processes.

6) Wide application

IPG lasers are widely used in the following fields:

- Metal cutting: including cutting of materials such as stainless steel, aluminum, carbon steel, etc., suitable for precision cutting of various types of plates.

- Welding: suitable for welding in automobile manufacturing, electronic products, precision equipment, etc.

- Marking and engraving: fine laser marking, laser engraving, etc., are widely used in consumer goods, electronic products, tools and other industries.

- Thin plate cutting: especially suitable for fast cutting of thin plate materials, and can maintain high precision.

7) Efficiency and energy saving

Fiber lasers have high electro-optical conversion efficiency, which can significantly reduce energy consumption. The high efficiency of IPG lasers not only helps companies reduce operating costs, but also meets the requirements of green environmental protection.

IPG fiber lasers occupy an important position in laser cutting machines due to their excellent stability, high power output, high-precision cutting and long service life. Although the price is relatively high, its excellent performance and low maintenance cost make it the first choice for many high-end applications.

If you have high requirements for cutting accuracy, efficiency, and stability, IPG laser is a brand worth investing in.

2. Introduction to Raycus Laser

Raycus is a Chinese-made laser brand that has emerged in the global laser market in recent years. As a very cost-effective choice, Raycus lasers have gradually become a popular choice in the mid-to-low-end market and some specific application scenarios. Here are some of the main features and advantages of Raycus lasers.

1) Technical background

Raycus laser uses fiber laser technology. Although its technology started late, through continuous research and development, Raycus has already acquired relatively mature laser production capabilities. The design of its fiber laser enables it to have high electro-optical conversion efficiency and stability, while the price is relatively affordable.

2) Performance characteristics

Output power:

The power range of fiber lasers provided by Raycus usually ranges from 500W to 10kW, suitable for different application scenarios such as cutting, welding, and marking.

IPG vs Raycus, Raycus’s high-power lasers (such as 10kW) are slightly inferior in some performance aspects, but they perform well in medium and low-power applications, meeting the needs of most small and medium-sized enterprises.

Cutting accuracy and speed:

- Accuracy:Raycus lasers have good accuracy in metal cutting, especially in thin plate cutting, and can achieve high cutting quality.

- Speed: Although Raycus’s cutting speed is slightly slower than IPG, it is sufficient to meet most needs in many small and medium-scale production.

Beam quality:

Raycus fiber lasers have good beam quality and are suitable for various precision cutting tasks, but compared with IPG, they may be slightly inferior under extremely high precision requirements.

Stability and reliability:

Raycus’ fiber lasers are relatively stable and suitable for daily production use, but they may not be as stable as IPG in long-term high-load continuous work.

3) Price advantage

High cost performance:

One of the biggest advantages of Raycus lasers is their low price, which is suitable for companies or small manufacturers with limited budgets. For customers who do not require high-end performance but want to control costs, Raycus lasers are undoubtedly a very attractive choice.

Low operating costs:

Compared with traditional CO2 lasers, fiber lasers have higher operating efficiency and lower energy consumption. Therefore, in the long production process, Raycus lasers can effectively reduce operating costs.

4) Applicable fields

The application fields of Raycus lasers are similar to those of IPG, but they are more inclined to the mid-to-low-end market, especially suitable for the following fields:

- Sheet metal processing: Raycus lasers are very suitable for sheet metal cutting, especially for small and medium-sized metal processing companies, and their high cost performance is a great attraction.

- Advertising industry: Laser engraving and cutting are widely used, and Raycus lasers can meet the needs of most advertising production.

- Home appliances and electronics industry: Raycus lasers also have good application performance in the processing of some thin plates and precision parts.

- Automotive industry: Especially suitable for cutting car bodies and parts, especially in medium and low power application scenarios.

5) Maintenance and after-sales service

Raycus lasers are relatively easy to maintain, and parts are easier to obtain, suitable for cost-sensitive users.

In terms of after-sales service, Raycus’s service system has been gradually improved, especially in the Chinese market with strong local support. However, compared with IPG, Raycus’s global service network and response speed may be slightly inferior.

6) Advantages and disadvantages

Advantages:

Relatively low price, high cost performance, suitable for companies with limited budgets.

High performance and long service life, simple maintenance.

Widely used, especially suitable for thin metal cutting, advertising production and other fields.

Domestic market support is good and the response speed is fast.

Disadvantages:

IPG vs Raycus, Raycus’s laser may not be stable enough in high-power, high-precision cutting tasks.

May not provide sufficient performance in extremely demanding applications (such as aerospace, precision manufacturing, etc.).

Long-term stability and maintenance frequency may require more attention and inspection compared to IPG.

Raycus laser is a very good low-end choice, especially for small and medium-sized enterprises that are more sensitive to budget. It provides high cost-effectiveness and stable performance, and performs very well in many applications. For some applications with high precision and high power requirements, IPG laser may be a better choice. But for general metal cutting, welding and marking, Raycus can provide very reliable support.

If you have a clear balance between performance and budget, Raycus is a brand worth considering.

3. Laser source comparison: IPG VS Raycus

IPG vs Raycus, they are two laser brands widely used in laser cutting machines. They each have their own advantages and different characteristics, suitable for different needs. The comparison between IPG and Raycus can be analyzed from multiple angles, including technical background, performance, price, applicable scenarios, etc.

Each brand has its own advantages and scope of application. When choosing, you need to consider the specific application requirements, budget and priority performance indicators. The following is a detailed comparison:

1) Technical background

IPG Laser:

IPG Photonics is the world’s leading fiber laser manufacturer. Their fiber lasers use high-power fiber laser technology, with high reliability and long service life. IPG’s lasers are generally considered to be mature in technology, stable in performance and high in precision.

- Foundation time and global influence: IPG Photonics was founded in 1990 and is headquartered in the United States. It is one of the world’s leading fiber laser manufacturers. IPG has strong technical accumulation and global market influence in the field of high-power laser technology.

- Technology maturity: IPG fiber lasers use efficient fiber gain media, and their beam quality, stability, precision and output power are at the world’s leading level, especially suitable for applications with high requirements for laser cutting precision and stability.

- Application areas: Widely used in high-end industries such as aerospace, automobile manufacturing, electronics, and metal processing.

Raycus Laser:

Raycus is a Chinese laser manufacturer. Raycus’ lasers are cost-effective and suitable for cost-sensitive applications.

- Foundation and development: Raycus was founded in 2007 and is a Chinese laser manufacturer. Although it was founded relatively late, through years of technological innovation, Raycus quickly occupied the domestic market and gradually gained a certain share in the international market.

- Technological development: Raycus focuses on the research and development and production of fiber lasers, and has a high cost-effectiveness in medium and low-power fiber lasers. Although it is not as good as IPG in some high-power or high-precision applications, it has a greater advantage in cost-effectiveness.

- Application areas: Mainly used in small and medium-sized enterprises, especially in sheet metal processing, advertising production, furniture and other industries with strong market competitiveness.

2) Performance comparison

Output power:

- IPG: IPG’s lasers can provide higher power (such as more than 10kW), suitable for high-power applications such as thick plate cutting and welding, with stable performance and suitable for industrial production.

- Raycus: Raycus’s lasers can also provide higher power, but are usually slightly inferior to IPG in terms of stability and reliability of high-power output, suitable for small and medium power and cost-intensive applications.

Cutting accuracy and speed:

- IPG: IPG’s lasers perform very well in accuracy and cutting speed, especially in high-precision cutting, suitable for occasions requiring high precision and fast production.

- Raycus: Raycus has a certain gap in cutting accuracy and speed, especially when cutting thin plates and precision parts, it may not be as stable as IPG.

IPG VS Raycus performance comparison table:

Performance | IPG | Raycus |

Beam quality | Very high, suitable for high-precision cutting and complex tasks | Good, suitable for general cutting, but not as fine as IPG |

Output power | High power output from 500W to more than 20kW | Usually from 500W to 10kW, suitable for medium and low power needs |

Cutting accuracy | Extremely high accuracy, suitable for high-precision processing | Good accuracy, but slightly inferior for high precision needs |

Cutting speed | High-speed cutting, especially in high-power applications | Relatively fast, but slightly slower in high power applications |

Stability | Very high, suitable for long-term continuous high-load work | Good stability, but slightly inferior to IPG under high loads |

Service life | Long service life, almost no need to replace the laser medium | Also has a longer service life, but may require more frequent maintenance |

Maintenance | Simple maintenance and perfect after-sales service | Low maintenance cost, more convenient domestic service |

3) Price

IPG Laser:

Due to its mature technology and brand influence, IPG’s lasers are more expensive and suitable for the high-end market with sufficient budget.

The price is mainly determined by the laser’s output power, beam quality, technical support and long-term stability.

Although the price is higher, its performance, reliability and long-term low maintenance cost make IPG a very worthwhile investment in high-end manufacturing.

Raycus Laser:

Raycus’ lasers have obvious price advantages, especially for small and medium-sized enterprises with limited budgets but need reliable fiber laser cutting. Raycus is a more cost-effective choice.

In a similar power range, Raycus’ laser price is about 60%-80% of IPG’s, so for price-sensitive customers, Raycus offers a better cost-effectiveness.

4) Stability comparison

IPG Laser:

IPG’s lasers have strong stability, long life, and long maintenance cycles, and are suitable for industrial environments that require continuous and efficient production. IPG also provides very good after-sales service to ensure the long-term stable operation of the equipment.

Raycus Laser:

Raycus’ lasers are relatively weak in stability and maintenance, but with the advancement of technology, Raycus is also gradually improving. The maintenance cost is lower, but more frequent inspections and maintenance may be required.

5) Market Application

IPG Laser:

Due to its excellent performance, IPG’s lasers are widely used in high-end manufacturing.

- High-end manufacturing: such as aerospace, automobile manufacturing, high-end electronic equipment, precision instruments, etc. These fields require laser cutting accuracy and stability, and IPG can provide top-level cutting quality and accuracy.

- High-power applications: IPG’s fiber lasers are excellent at high power output (such as 10kW and above), suitable for applications with high power requirements such as thick plate cutting and deep cutting.

Raycus Laser:

Raycus’ lasers are widely used in the low- and medium-end markets, especially in metal sheet cutting, sheet metal processing, advertising production and other fields.

- Small and medium-sized manufacturing: Raycus’ lasers are more suitable for small and medium-sized enterprises, especially in sheet metal processing, advertising production, furniture, home appliances and other industries.

- Occasions with high cost-effectiveness requirements: Raycus fiber lasers are suitable for price-sensitive applications with medium cutting quality requirements, such as thin sheet metal cutting.

6) After-sales service and support

IPG:

Provides global after-sales service and technical support, with a wide after-sales network, especially providing more thoughtful technical support in the high-end market.

It has a complete service system both at home and abroad, with a fast response speed, which can ensure the long-term stable operation of the equipment.

Raycus:

Raycus has strong localized service support in the Chinese market, and its after-sales service response speed is relatively fast.

In the international market, Raycus’ after-sales service is gradually improving, but it may not be as good as IPG in terms of response speed and technical support in some regions.

4.Summary

IPG VS Raycus Laser:

- IPG fiber lasers are more suitable for industries that have extremely high requirements for laser cutting accuracy, stability, continuous operation and high-power applications. Although they are more expensive, they are unmatched in the high-end market.

- Raycus fiber lasers are more suitable for small and medium-sized enterprises with limited budgets and not extremely high requirements for cutting accuracy and stability. Raycus is cost-effective and can meet general production needs while providing sufficient performance and reliability in many applications.

If your application is mainly high-precision, high-intensity laser cutting, or your industry requires extremely high stability, then IPG may be a better choice. If your budget is more limited and the performance requirements are moderate, Raycus will be a very cost-effective choice.

According to your actual needs (such as cutting materials, cutting accuracy requirements, production scale, etc.), you can choose the right laser brand.