Table of Contents

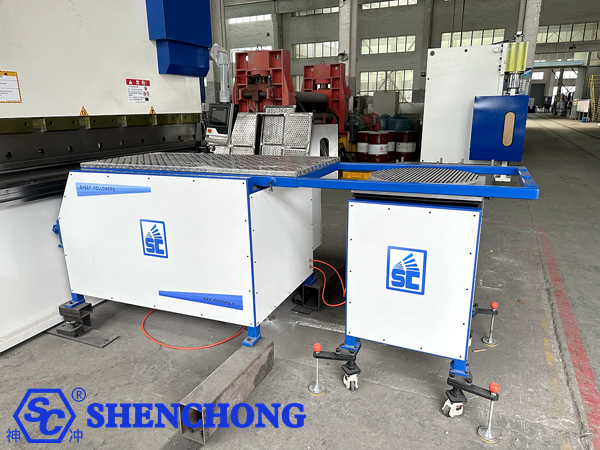

SC independent bending follower device for press brake is an auxiliary bending device that is used to intelligently support and follow-up adjust the workpiece during the bending process to prevent the workpiece from losing bending accuracy due to gravity, deformation or operating errors. The device operates independently of the main press brake machine, but can be linked with the CNC control system to achieve precise and synchronous bending support functions.

1. What is an independent bending follower for press brake?

SC independent bending follower is an intelligent auxiliary system for supporting and synchronously moving the plate. It can automatically adjust the support force according to the bending angle, position and speed to reduce the deformation of the workpiece, improve the bending accuracy and reduce the burden on the operator.

The device is independent of the main machine of the CNC press brake and can realize follow-up support according to the bending process requirements. It works synchronously with the movement of the slider to keep the workpiece in a reasonable support state at all times.

2. Main functions and effects of independent sheet follower

1) Plate support function

During the bending process, especially for longer, thinner or heavier plates, the follower device can provide appropriate support to prevent sagging and deformation caused by gravity or deadweight.

2) Automatic follower adjustment

The device is usually driven by a servo motor or hydraulic system, and combined with a numerical control system (CNC), it can adjust the support force, lifting height and angle in real time to match the descending speed and angle of the slider.

3) Correcting bending errors

Since the plate will rebound during bending, the independent follower device can reduce the uneven deformation of the plate due to inertial sagging, and improve the bending accuracy and consistency.

4) Reduce manual labor intensity

In traditional manual bending, the operator is required to provide support under the workpiece, especially for super-long, super-wide or heavy workpieces, which is labor-intensive and difficult to operate. The follower device can automatically support and move, greatly reducing manual operation and improving safety and production efficiency.

3. SC independent bending follower composition and configuration

The press brake independent follower generally consists of the following parts.

Component table:

Component Name | Key Features |

Support platform | Responsible for carrying the workpiece, the surface is usually made of wear-resistant material to reduce friction and improve stability. |

Servo motor | Responsible for driving the follower device to rise and fall, move forward and backward, and achieve automatic synchronous support. |

Sensor system | Monitor the position, bending angle and pressure of the plate to optimize the support strength |

Control system | Control the follower device through an independent PLC to achieve precise synchronous control |

Detailed Configuration of SC independent bending follower device:

- It can be equipped with all brands and models of top-moving press brakemachines (hybrid CNC press brake machines, electro-hydraulic press brake machines, torsion axis bending machines).

- The main body is an independent structure, and there is no need to change the mechanical parts of the bending machine. The base is a Fuma wheel structure that can be moved at any time.

- The support table is equipped with a universal ball to facilitate the movement and rotation direction of the workpiece, conducive to bending the workpiece.

- The height of the support table can be fine-tuned up and down, convenient for installing molds of different heights.

- Independent PLC control system, using magnetic scale to feedback information to the computer. The computer controls the servo motor closed loop to perform follow-up action.

- The follow-up flipping speed can be adjusted according to different plate thicknesses. There is no need to change the bending machine control system, and standard bending does not require programming. The human-machine interface can be programmable or manually operated.

- No need to modify the bending machine. You only need to drill a hole in the slider of the bending machine to install a displacement sensor, and connect it to the incoming line interface of the bending machine to use it. Avoid the risk of failure caused by modifying the bending machine electrical box and taking the bending machine signal. It also avoids industrial accidents such as the bending machine’s blade dropping and pressing the operator’s hand due to interference of the bending machine signal by the bending follwer.

4. Features and advantages of independent bending follow-up device

1) Equipment features

Independent control system:

The device is independent of the bending machine and can be intelligently synchronized according to the movement of the bending machine without directly relying on the hydraulic or mechanical drive of the bending machine.

The support force and motion trajectory can be adjusted independently through PLC.

Intelligent follow-up function:

The servo motor, hydraulic drive or pneumatic system can automatically adjust the support height and angle according to the bending angle, slider position and workpiece deformation.

Keep synchronization with the plate during the bending process to avoid accuracy errors caused by plate sagging.

High-precision sensor:

The photoelectric sensor, laser distance sensor or pressure sensor monitors the plate position in real time and makes dynamic adjustments to improve the bending accuracy.

Strong compatibility:

It is compatible with various brands and models of bending machines, and realizes intelligent linkage through independent CNC system or external data interface.

2) Main advantages

Improve bending accuracy:

Avoid bending errors caused by plate sagging or rebound, ensure consistent bending dimensions each time, and improve product quality.

Reduce manual operation intensity:

When traditional bending machines process large-sized workpieces, multiple operators are required to lift and adjust the plates. The follower device can automatically complete these operations, reduce manpower requirements, and reduce labor intensity.

Improve production efficiency:

Due to the high degree of automation, manual intervention and adjustment time are reduced, making the production rhythm more stable and improving overall processing efficiency.

Wide range of application:

It can be used for bending various types of plates such as long, thin, thick, and heavy, and is suitable for aerospace, automobile manufacturing, home appliances, machinery manufacturing, steel structure and other industries.

Cost savings:

Reduce labor costs, reduce scrap rates caused by human operating errors, and at the same time reduce equipment maintenance costs and increase equipment service life.

Improve security:

Due to the reduction of manual operations, safety hazards such as falling and extrusion of heavy workpieces are reduced, and the safety of the working environment is improved.

5. Application of independent bending follower

The independent bending follower device plays an important role in sheet metal processing, machinery manufacturing, aerospace, automobile manufacturing and other industries, and is especially suitable for large-size, heavy or high-precision sheet bending operations. It can provide automatic support, synchronous follow-up and precision control, thereby improving processing quality and production efficiency.

1) Main application scenes

Bending of long plates

Application scenes: aviation, building curtain walls, cabinet manufacturing

Challenging:

- Long plates (for example, more than 6 meters) are prone to sagging due to their own weight during the bending process, resulting in uneven bending angles or errors.

- Many operators are required to lift them manually, which is inefficient and unsafe.

Function of the follower device:

- Provide support for the plate, so that it moves synchronously with the slider of the bending machine to prevent sagging and deformation.

- Improve bending accuracy and reduce rework rate.

Heavy plate bending

Application scenarios: steel structure, bridge manufacturing, construction machinery

Challenges:

- Heavy steel plates (thickness ≥ 8mm) are difficult to carry when bending, and it is difficult for manual support and precise position.

- Manual operation can easily cause bending errors, affecting welding and subsequent assembly.

Function of follow-up device:

- Provide stable support, reduce manual burden, and prevent workpieces from slipping.

- Through the intelligent control system, automatic follow-up adjustment is achieved to improve bending accuracy.

Ultra-thin sheet bending

Application scenarios: home appliance industry (refrigerator, washing machine panel), electronic equipment housing

Challenges:

- Thin sheets (0.5-2mm) are prone to warping or rebound due to uneven stress during the bending process, affecting the quality of the finished product.

Function of the follower device:

- By automatically adjusting the support angle, reduce bending rebound and improve product consistency.

- Prevent material scratches and improve appearance quality.

Bending of irregular-shaped plates

Application scenarios: sheet metal special-shaped parts manufacturing, aerospace components

Challenges:

Complicated-shaped plates are subjected to uneven force during the bending process, which can easily cause local deformation or bending errors.

Function of follow-up device:

Through multi-axis linkage control, it can adapt to plates of different shapes and achieve precise support and bending.

2) Applicable industry forms

Industry | Application Examples |

Aerospace | Bending of large aluminum alloy sheets (such as wing skins) |

Automobile manufacturing | Bending of vehicle body sheet metal parts, doors and hoods |

Home appliance industry | Processing of thin plates such as refrigerator casings and washing machine panels |

Construction industry | Bending of stainless steel curtain walls and decorative panels |

Steel structure manufacturing | Bending of bridges and heavy machinery structures |

Independent bending follow-up devices are widely used in bending operations that require high precision, large size, heavy weight or complex shapes. They can effectively improve processing accuracy, reduce manual operations, and improve production efficiency and safety. They are indispensable intelligent auxiliary equipment for modern press brake bending machines.

6. Summary

SC independent bending follower device is an important auxiliary device for modern CNC press brake machines, which can automatically adjust the height, angle and position of the supported workpiece. The independent follower of the bending machine is an efficient intelligent device that can significantly improve the bending accuracy, reduce the deformation of the workpiece, reduce the difficulty of manual operation, and improve the overall production efficiency. It is particularly suitable for bending processing of super-long, super-wide, super-heavy or high-precision plates, and is widely used in sheet metal processing, aerospace, automobile manufacturing and other industries.