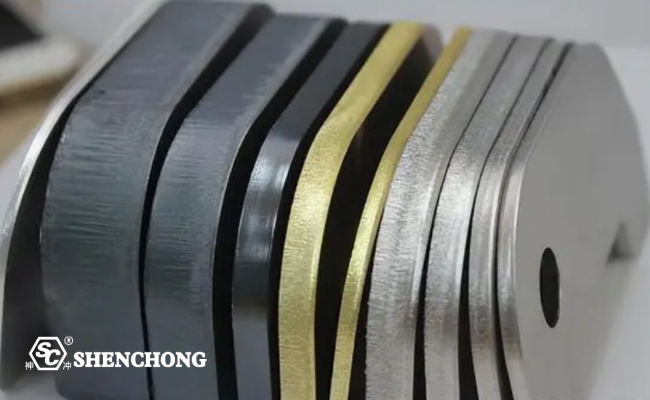

In the current sheet metal processing industry, the usage range of laser equipment has become more and more wide. Fiber laser cutting technique is quite mature and has large market share in the metal cutting industry. However, how to choose suitable fiber laser cutting machine power? This is the first problem for clients who want to purchase fiber laser cutting machine. This article will introduce the relationship between laser cutting machine power and metal sheets.

1. What is Fiber Laser Cutting Machine?

Fiber laser cutting machine is a laser cutting equipment that uses fiber laser as the light source.

The high-energy density laser beam output by the fiber laser is focused on the surface of the workpiece, causing the irradiated area to instantly melt and vaporize. The cutting is automatically completed by moving the laser beam’s irradiation position through a CNC mechanical system. Compared with traditional gas lasers and solid-state lasers, fiber laser cutting machine has significant advantages such as small volume, light weight, high photoelectric conversion rate, space saving, and gas consumption.

In addition, fiber laser cutting machine is suitable for precision cutting of various materials such as metal plates, and have the characteristics of fast cutting speed, high precision, and high efficiency.

When clients want to purchase a fiber laser cutting machine, the first step is to determine the fiber laser cutting machine model, and they need to confirm the fiber laser cutting machine power for the machine.

Click here to know more about What Is Laser Cutting Machine.

2. Factors Affect The Fiber Laser Cutting Machine Power

2.1 Sheet Metal Types and Thickness

Before clients buy the fiber laser cutting machine, they need to know their business scope, sheet metal material type, metal thickness, and so that they can determine what fiber laser cutting machine power is their best choice.

Nowadays, fiber laser cutting machines in China are divided into three different types: low power fiber laser cutting machine, medium power fiber laser cutting machine, and high power fiber laser cutting machine. Generally speaking, low-power fiber laser cutting machine manufacturers are the most concentrated in the market. Due to mature laser technology and low entry barriers, these manufacturers continuously simplify laser cutting machines and material cutting to achieve maximum profit. Therefore, choosing a low-power laser cutting machine must choose a laser cutting machine factory with quality assurance.

Since producing medium power and high power fiber laser cutting machines requires the factory has high tech engineer team and full experienced workers, there is less medium and high power laser cutting machine factories than low-power laser cutting machine manufacturers in the market.

Usually, we refer to laser cutting machines below 1000W-6000W as low-power laser cutting machines, 6000W-15000w as medium power laser cutting machines and fiber laser cutting machine power above 15000w counted as high power.

2.1.1 Comparison Table

Material thickness: Usually, we use the thickness of two commonly used materials as the main basis for selecting laser power.

At this time, the thickness range of laser cutting materials is:

The laser cutting machine with a power of 1000W can cut carbon steel with a thickness of 0.8-10mm; Cutting stainless steel thickness: 0.8-5mm.

A 1500W laser cutting machine can cut carbon steel with a thickness of 1-16mm; Cutting stainless steel thickness: 1-6mm.

The laser cutting machine with a power of 2000W can cut carbon steel with a thickness of 1-20mm; Cutting stainless steel thickness: 1-8mm.

The laser cutting machine with a power of 3000W-3300W can cut carbon steel with a thickness of 1-22mm; Cutting stainless steel thickness: 1-10mm.

The laser cutting machine with a power of 4000W can cut carbon steel with a thickness of 1-25mm; Cutting stainless steel thickness: 1-15mm.

The sheet fiber laser cutting machine with a power of 6000W can cut carbon steel with a thickness of 1-30mm; Cutting stainless steel thickness: 1-20mm.

The laser cutting machine with a power of 8000W can cut carbon steel with a thickness of 1-40mm; Cutting stainless steel thickness: 1-30mm.

The laser cutting machine with a power of 10000W can cut carbon steel with a thickness of 1-45mm; Cutting stainless steel thickness: 1-40mm.

The laser cutting machine with a power of 12000W can cut carbon steel with a thickness of 1-50mm; Cutting stainless steel thickness: 1-45mm.

The laser cutting machine with a power of 15000W can cut carbon steel with a thickness of 1-60mm; Cutting stainless steel thickness: 1-50mm.

For plates thickness more than 60mm, please kindly contact with fiber laser cutting machine manufacturer for professional fiber laser cutting machine power recommendation.

2.2 Speed And Fiber Laser Cutting Machine Power

There is a certain relationship between the cutting speed and fiber laser cutting machine power. Generally speaking, the higher the power, the faster the cutting speed. This is because the cutting speed of a laser cutting machine mainly depends on the thermal input of the laser beam into the material and the melting or evaporation rate of the material.

In laser cutting, high-power laser beams can heat materials faster to the temperature of melting or evaporation, thereby increasing cutting speed. Therefore, increasing the fiber laser cutting machine power can improve cutting speed and reduce cutting time.

In this case, clients not only need to think about the sheet metal thickness and material types, but also need to consider the production requirements before they determine the machine power to purchase.

3. Future Development

3.1 Large Power

The development speed of fiber laser cutting machine is incredibly fast. Several years ago, fiber laser cutting machine is best to cut thin plate, which thickness should below 30mm. To cut mild sheet plate thickness above 30mm, people used to choose plasma cutting machines or flame cutting machines. However, nowadays in China market, we have 100000w and 120000w large power fiber laser cutting machine to cut the mild plates thickness above 100mm. China market of fiber laser cutting machine is so competitive, and factories are focus on developing the large fiber laser cutting machine power.

3.2 Multi-Function

In the future, fiber laser cutting machines will have more diverse functions and applications, such as cutting, punching, carving, etc. At the same time, a laser cutting machine will also have more applications, which can be suitable for cutting different materials, sizes, and shapes, improving the flexibility and adaptability of the equipment. Many sheet metal automation factories provide the sheet and tube fiber laser cutting machine for sale.

3.3 Automation And Intelligence

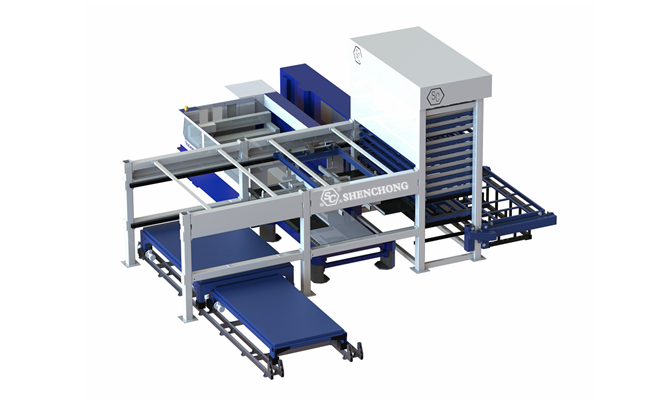

In the future, laser cutting machines will pay more attention to the development of laser automation. By using automatic loading unloading system for laser cutting machine and intelligent metal storage system, clients can improve production efficiency, reducing costs, and reducing manual intervention.

Source: