Table of Contents

Introduction

Hydraulic press machines are versatile and powerful tools used in various industries, including automotive, aerospace, metalworking, and manufacturing. These machines utilize hydraulic pressure to generate substantial force, enabling them to perform tasks such as forging, stamping, bending, and forming materials. When considering the purchase of a hydraulic press machine, one of the most critical factors is its cost. The price of a hydraulic press machine can vary significantly based on several factors, including its type, capacity, features, and the manufacturer. This comprehensive article will explore the various aspects that influence the hydraulic press machine cost, provide an overview of different types and their typical price ranges, and offer insights into additional costs and considerations associated with purchasing and owning a hydraulic press machine.

Hydraulic Press Machine Overview

A hydraulic press is a machine that uses hydraulic cylinders to generate a compressive force. It operates based on Pascal’s principle, which states that pressure applied to a confined fluid is transmitted equally in all directions. This principle allows the press to multiply force, enabling it to exert a significant amount of pressure with relatively little input force.

Applications

Hydraulic presses are used in a wide range of industries due to their versatility and ability to generate high forces. Common applications include:

- Metal forming:Bending, stamping, and shaping metal parts.

- Plastic and rubber molding:Compressing material into molds to create shapes.

- Powder compacting:Forming solid objects from powdered materials.

- Assembly operations:Press fitting components together.

- Laboratory testing:Measuring the strength of materials.

Hydraulic presses are favored for their ability to deliver consistent, controlled force and their capacity to handle a wide range of tasks, making them essential equipment in many manufacturing processes.

Key Components Of A Hydraulic Press

- Hydraulic Cylinder:The main component where fluid is pressurized to generate force. It typically contains a piston that moves within the cylinder to apply force to the workpiece.

- Hydraulic Pump:This component generates the necessary fluid pressure by moving hydraulic fluid into the cylinder. The pump can be powered by an electric motor or manually operated.

- Hydraulic Fluid:A specially formulated oil that is used to transmit pressure within the system. The fluid must be kept at the correct level and free of contaminants to ensure proper operation.

- Frame:The structure that supports the components and resists the force exerted during the pressing operation. Hydraulic presses can have different frame designs, such as C-frame or H-frame, depending on their intended use.

- Press Bed:The surface where the workpiece is placed. The press bed supports the workpiece during the pressing operation and often includes tooling or dies.

- Control System:This includes the mechanisms (such as levers, buttons, or programmable controls) used to operate the press, adjust settings, and ensure safety.

Factors Consider Before Purchasing A Hydraulic Press Machine

When buying a hydraulic press, there are several key factors to consider to ensure you choose the right machine for your needs:

1. Tonnage Capacity

- Determine the Required Force:The tonnage capacity should match or exceed the force required for your specific applications. Underestimating this can lead to machine damage or failure, while overestimating can result in unnecessary costs.

2. Bed Size

- Consider the Workpiece Size:The bed size should accommodate the largest workpiece you plan to work with. Ensure there’s enough clearance for any tooling or fixtures.

3. Stroke Length

- Evaluate Depth Requirements:The stroke length, which determines how far the ram can travel, should be sufficient for the depth of the operations you need, such as deep drawing or punching.

4. Speed

- Cycle Time Efficiency:The speed of the press, including the ram speed, can impact production efficiency. Faster speeds may be necessary for high-volume production.

5. Frame Type

- C-Frame vs. H-Frame:C-frames are more accessible and suitable for smaller applications, while H-frames provide more rigidity and are better for handling higher tonnage.

6. Control System

- Ease of Use and Precision:Look for user-friendly controls, especially if you need precise adjustments. Consider whether the press has a programmable logic controller (PLC) for automation and consistency.

7. Hydraulic System Quality

- Reliability and Maintenance:The quality of the hydraulic system, including pumps, valves, and cylinders, is critical. Check for robust construction and ease of maintenance.

8. Safety Features

- Operator Protection:Ensure the press includes safety features such as guards, emergency stops, and safety interlocks to protect operators during use.

9. Energy Efficiency

- Operating Costs:Consider the energy consumption of the press, as more efficient machines can reduce long-term operating costs.

10. Brand Reputation and Support

- After-Sales Service:Research the manufacturer’s reputation for quality and customer support. Reliable technical support and readily available spare parts are crucial for minimizing downtime.

11. Customization and Versatility

- Adaptability to Future Needs:Determine whether the press can be customized or upgraded to handle different tasks or increased capacity in the future.

12. Budget

- Cost vs. Value:While it’s important to stay within budget, ensure that the press offers good value in terms of durability, features, and efficiency.

By carefully considering these factors, you can choose a hydraulic press that meets your specific requirements and delivers reliable performance over time.

Factors Influencing the Hydraulic Press Machine Cost

Main Factors Affect The Hydraulic Press Machine Price

1. Type Of Hydraulic Press

The type of hydraulic press machine is one of the primary factors influencing its cost. There are several types of hydraulic presses, each designed for specific applications and offering varying levels of complexity and functionality.

- H-Frame Hydraulic Press: Known for its versatility and commonly used in general manufacturing, metalworking, and automotive repair shops. H-frame presses are relatively affordable compared to other types.

- C-Frame Hydraulic Press: Offers three-sided access, making it ideal for tasks requiring easy loading and unloading of materials. C-frame presses are typically more expensive than H-frame presses due to their specialized design.

- Four-Column Hydraulic Press: Provides uniform force distribution and high stability, suitable for heavy-duty operations and large-scale production. Four-column presses are among the more expensive types due to their robust construction and capabilities.

- Bench-Top Hydraulic Press: Compact and portable, used for small-scale operations and laboratory applications. Bench-top presses are usually the least expensive type due to their smaller size and lower capacity.

- Straight-Side Hydraulic Press: Designed for high-precision tasks and heavy-duty applications, often used in the automotive and aerospace industries. These presses are among the most expensive due to their advanced features and high performance.

2. Capacity And Force

The capacity of a hydraulic press, measured in tons, directly affects its cost. Higher-capacity presses capable of generating more force are generally more expensive. The capacity required depends on the specific application and material being processed.

- Low-Capacity Presses: Typically range from 1 to 30 tons, used for light-duty tasks such as assembly, repair, and small-scale production. These presses are relatively affordable.

- Medium-Capacity Presses: Range from 30 to 200 tons, suitable for medium-duty applications such as forming, bending, and punching. The cost of these presses is moderate, depending on additional features.

- High-Capacity Presses: Exceed 200 tons, designed for heavy-duty applications such as forging, deep drawing, and large-scale manufacturing. High-capacity presses are the most expensive due to their power and capabilities.

3. Features And Customization

Additional features and customization options can significantly impact the hydraulic press machine cost. Common features that influence pricing include:

- Automation: Automated hydraulic presses with programmable logic controllers (PLCs), human-machine interfaces (HMIs), and robotic integration for material handling are more expensive due to the added complexity and technology.

- Precision Controls: Presses with advanced control systems for precise pressure, speed, and position adjustments are costlier than basic models.

- Tooling and Accessories: Specialized tooling, dies, and accessories required for specific applications can increase the overall cost.

- Safety Features: Enhanced safety features such as light curtains, safety interlocks, and emergency stop systems add to the cost but are essential for ensuring operator safety.

4. Brand And Manufacturer

The brand and reputation of the manufacturer play a significant role in the hydraulic press machine cost. Established brands with a history of producing high-quality and reliable equipment often command higher prices. Additionally, manufacturers offering comprehensive after-sales support, warranties, and service packages may charge a premium for their products.

5. Geographic Location

The geographic location of the manufacturer and the buyer can affect the cost of a hydraulic press machine. Factors such as import/export duties, shipping costs, and regional market conditions can influence pricing. Buyers in regions with a higher cost of living or stricter regulations may also face higher prices.

Additional Hydraulic Press Machine Cost and Consideration

1. Installation And Setup

The installation and setup of a hydraulic press machine can incur additional costs. This includes expenses related to transportation, rigging, and positioning of the machine, as well as any necessary modifications to the facility to accommodate the press.

2. Maintenance And Repairs

Regular maintenance is essential to ensure the optimal performance and longevity of a hydraulic press machine. Costs for maintenance, repairs, and replacement parts should be factored into the overall investment. Manufacturers may offer maintenance contracts or service packages to cover these expenses.

3. Energy Consumption

Hydraulic presses can be energy-intensive, particularly high-capacity models. The cost of energy consumption should be considered, especially in regions with high electricity rates. Energy-efficient models may have higher upfront costs but can result in long-term savings.

4. Training and Labor

Operators and maintenance personnel may require training to effectively use and maintain the hydraulic press machine. Training costs, as well as the labor costs for operating the press, should be included in the overall budget.

5. Safety Compliance

Ensuring that the hydraulic press machine complies with local safety regulations and standards is crucial. This may involve additional costs for safety equipment, certifications, and modifications to the machine.

Typical Price Ranges for Different Types of Hydraulic Press Machines

1. H-Frame Hydraulic Press Cost

- Low-Capacity (1-30 tons): $1,000 to $5,000

- Medium-Capacity (30-200 tons): $5,000 to $20,000

- High-Capacity (200+ tons): $20,000 to $50,000 or more

2. C-Frame Hydraulic Press Cost

- Low-Capacity (1-30 tons): $2,000 to $7,000

- Medium-Capacity (30-200 tons): $7,000 to $25,000

- High-Capacity (200+ tons): $25,000 to $60,000 or more

3. Four-Column Hydraulic Press Cost

- Low-Capacity (1-30 tons): $3,000 to $10,000

- Medium-Capacity (30-200 tons): $10,000 to $40,000

- High-Capacity (200+ tons): $40,000 to $100,000 or more

4. Bench-Top Hydraulic Press Cost

- Low-Capacity (1-30 tons): $500 to $3,000

- Medium-Capacity (30-200 tons): $3,000 to $10,000

- High-Capacity (200+ tons): Not typically available in bench-top configurations

5. Straight-Side Hydraulic Press Cost

- Low-Capacity (1-30 tons): $10,000 to $30,000

- Medium-Capacity (30-200 tons): $30,000 to $70,000

- High-Capacity (200+ tons): $70,000 to $150,000 or more

Leading Manufacturers and Hydraulic Press Machine Price

1. Enerpac

Enerpac is a well-known manufacturer of hydraulic equipment, including presses. They offer a range of hydraulic presses from small bench-top models to large industrial presses. Enerpac’s reputation for quality and reliability often places their products in the higher price range.

2. Dake

Dake specializes in industrial presses, including hydraulic presses. They offer a variety of models suitable for different applications, from light-duty to heavy-duty tasks. Dake presses are known for their durability and performance, with prices varying based on capacity and features.

3. Baileigh Industrial

Baileigh Industrial offers a wide range of hydraulic presses, from small shop presses to large industrial models. Their presses are designed for precision and efficiency, catering to various industries. Baileigh’s pricing is competitive, with options for different budgets and requirements.

4. Beckwood Press

Beckwood Press is renowned for its custom-engineered hydraulic presses designed to meet specific customer needs. They offer a range of standard and custom presses with advanced features and capabilities. Beckwood’s presses are typically on the higher end of the price spectrum due to their custom solutions and high performance.

5. PHI Hydraulics

PHI Hydraulics manufactures high-quality hydraulic presses for various applications, including metalworking, plastic molding, and composite forming. Their presses are known for their robustness and precision, with pricing reflecting the advanced technology and customization options available.

Case Studies: Cost Analysis Of Hydraulic Press Purchases

1. Automotive Manufacturer

An automotive parts manufacturer required a high-capacity hydraulic press for forming metal components. After evaluating several options, they selected a 300-ton four-column hydraulic press with advanced automation features. The total cost, including installation, training, and a three-year maintenance contract, was approximately $120,000. The investment resulted in a 30% increase in production efficiency and a 20% reduction in labor costs.

2. Aerospace Supplier

A supplier of aerospace components needed a precision hydraulic press for forming titanium parts. They opted for a 150-ton straight-side hydraulic press with CNC controls and automated tool changers. The total investment, including installation and operator training, was $90,000. The press provided the required precision and consistency, leading to a 25% improvement in product quality and a 15% reduction in material waste.

3. Metal Fabrication Shop

A metal fabrication shop required a versatile hydraulic press for various forming and bending tasks. They chose a 50-ton H-frame hydraulic press with manual controls and basic safety features. The total cost, including delivery and setup, was $15,000. The press met the shop’s needs, providing reliable performance and contributing to a 20% increase in productivity.

Future Trends In Hydraulic Press Technology And Pricing

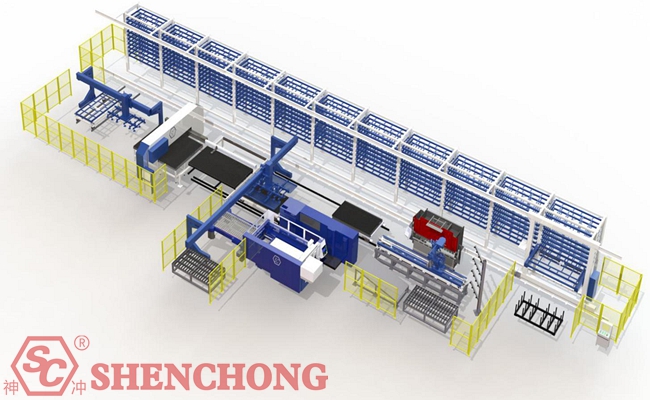

1. Automation and Industry 4.0 Integration

The integration of automation and Industry 4.0 technologies is driving advancements in hydraulic press machines. Features such as IoT connectivity, real-time monitoring, and predictive maintenance are becoming more common, enhancing efficiency and reducing downtime. While these technologies may increase the upfront cost, they offer long-term benefits and cost savings. Hydraulic press automatic production line is the future trend in the sheet metal forming industry.

2. Energy Efficiency and Sustainability

Manufacturers are increasingly focusing on energy-efficient designs to reduce the environmental impact and operational costs of hydraulic presses. Innovations such as servo-hydraulic systems, which combine hydraulic power with electric servo motors, are gaining popularity. These systems offer precise control and lower energy consumption, resulting in cost savings over the machine’s lifespan.

3. Customization and Flexibility

The demand for customized hydraulic press solutions tailored to specific applications is growing. Manufacturers are offering more flexible and modular designs that can be adapted to different tasks and production requirements. While customized presses may have higher initial costs, they provide greater value and efficiency for specialized operations.

4. Enhanced Safety Features

Advancements in safety technology are leading to the development of hydraulic presses with improved safety features. Innovations such as light curtains, advanced interlock systems, and real-time safety monitoring enhance operator safety and reduce the risk of accidents. These features, while adding to the cost, are essential for ensuring compliance with safety regulations and protecting workers.

Conclusion

The hydraulic press machine cost can vary widely based on factors such as type, capacity, features, manufacturer, and geographic location. Understanding these factors and considering additional costs such as installation, maintenance, energy consumption, and training is crucial for making an informed investment.

Hydraulic presses offer significant benefits, including high force, versatility, and precision, making them indispensable in various industries. As technology continues to advance, hydraulic press machines are becoming more efficient, automated, and customizable, offering greater value to manufacturers.

By carefully evaluating the specific needs of their operations and selecting the right hydraulic press machine, businesses can enhance productivity, improve quality, and achieve long-term cost savings. The insights provided in this comprehensive article aim to guide buyers in making informed decisions and maximizing the benefits of their investment in hydraulic press technology.