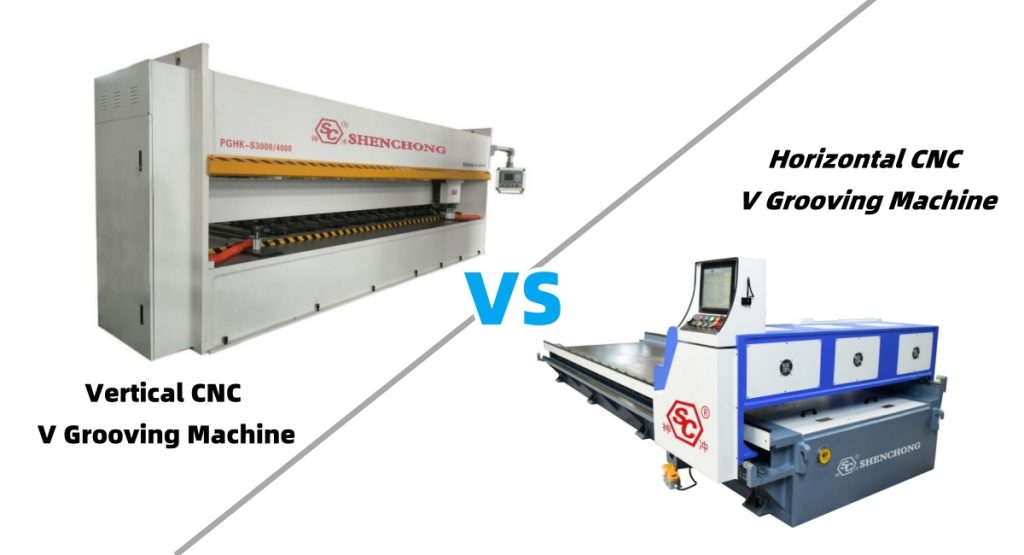

What Is CNC V Grooving Machine?

Compared horizontal cnc v groove machine vs vertical v groove machine, users need to know their structures and functions. The CNC sheet metal V grooving machine can create V-shaped grooves on stainless steel sheets, iron sheets, aluminum sheets, composite aluminum sheets, copper sheets, and other metal sheets, making the edge radius of the bent workpiece smaller, meeting the special needs of high-end metal sheet metal decoration in hotels, restaurants, restaurants, commercial buildings, banks, airports, and other places.

Vertical CNC V Grooving Machine

Vertical CNC V grooving machine is a machine tool equipment used for sheet metal processing grooves. It has the advantages of simple structure, convenient operation, and high processing efficiency, and is widely used in industries such as metal processing, mechanical manufacturing, and automotive manufacturing.

Vertical CNC V Groove Machine Structure

The structure of a vertical CNC V grooving machine mainly includes parts such as the machine bed, slide seat, workbench, spindle box, planer frame, etc. The machine frame is the foundation of the entire machine tool, bearing the active force of the grooving blades and the weight of the workpiece being processed. Sliding seat is used to support and guide the movement of the workbench. It slides longitudinally on the bed, allowing the workbench to move horizontally or longitudinally. A worktable is a tray for processing workpieces on a V grooving machine, usually composed of adjustable fixtures and worktable planes. The spindle box includes the main spindle, main motor, gearbox, and other parts. The main spindle is driven by the motor to rotate and drive the planer for cutting processing. The CNC V grooving machine frame is a structural component installed on the spindle box, used to support and fix the blade.

Working Steps

The working principle of a vertical V grooving machine is to drive the grooving blade through the rotation of the spindle for cutting processing. The specific workflow can be divided into the following steps:

- Place the workpiece to be processed on the workbench and fix it with a fixture.

- Turn on the main motor to start the spindle rotation. At the same time, the workbench can be moved horizontally or vertically to determine the position of the groove.

- Adjust the grooving bladeon the bladeholder to ensure that the gap between it and the workpiece is appropriate. The vertical cnc V grooving machine frame usually has multiple positions, and different positions of the planer can be selected according to the processing requirements.

- Start processing. When the spindle drives the grooving bladeto come into contact with the workpiece, the grooving bladebegins to cut metal, forming a groove. The cutting force of the planer is mainly provided by the main motor, and the movement of the worktable also helps to smooth the cutting process.

After the processing is completed, stop the main motor and wait for the grooving blade to completely stop rotating, then take out the processed workpiece.

CNC Horizontal V Grooving Machine

The horizontal CNC V groove machine is a common processing equipment in the sheet metal industry, mainly used for processing stainless steel sheets, galvanized sheets, iron sheets, aluminum sheets, copper sheets, etc. The main characteristics of the horizontal V slotting machine are fast slotting speed, high accuracy, and the use of CNC technology to accurately control the depth, width, and shape of cutting, ensuring machining accuracy and quality. It can move quickly to achieve high-speed cutting and improve machining efficiency. The horizontal CNC grooving machine adopts a CNC system, which can be easily programmed and controlled. The operation is simple and convenient, and it can meet the processing needs of various boards. Mainly used for planing large workpieces, it can also hold multiple workpieces for processing at the same time. In the process of gantry CNC V groocing machining, the workpiece moves with the worktable, the workpiece mainly moves, and the tool only feeds.

Advantages And Disadvantages Of Horizontal CNC V Grooving Machine And Vertical CNC V Grooving Machine

According to different grooving requirement from users, CNC sheet metal V-groove machines are designed in two mainstream types: vertical and horizontal. The horizontal V grooving machine originated from South Korea and has been highly sought several years ago. After using it, many people realized its drawbacks, which are due to the wrong design concept of the equipment and can be summarized in the following aspects:

- Speed: The grooving speed of horizontal CNC Vgroove machine is slower than the vertical one. Generally, if the return speed of a horizontal type V grooving machine exceeds 50m/min, there will be a phenomenon of “speeding”. The return speed of a sheet metal vertical V grooving machine from a general manufacturer is 80-100m/min.

- Accuracy: The accuracy of the horizontal CNC Vgroove machine is lower than that of the vertical one. The accuracy of a typical manufacturer’s horizontal type is 2-0.3mm. The accuracy of a typical vertical manufacturer is 0.05mm or more. The depth of the groove is directly related to the effect of the bending angle. If the depth error reaches more than 0.05mm, the bending position R will be significantly different, resulting in poor quality of the finished workpiece after bending.

- Advantages of processing technology: The working table of a vertical grooving machine is generally made of 45 # material used by manufacturers. The worktable of the horizontal Vgroove machine is generally made by manufacturers using ordinary iron plates welded and processed. When processing materials harder than the workbench, it is easy to damage the workbench and cause potholes, which can cause spots on the processed product. The working table of the vertical V grooving machine is made of high-quality mold steel that has been fully heat treated and finely ground by a grinder, with a mirror like appearance.

- Energy consumption: When a CNC vertical V grooving machine is used for grooving metal sheets, the tool holder moves back and forth, with a weight of about 60kg. When a CNC horizontal V grooving machine is used for cutting, the gantry and tool holder move back and forth together, with a weight of about 1000kg.Its energy loss is more than 10 times that of a vertical grooving machine. Therefore, a vertical V grooving machine is an energy-saving and environmentally friendly equipment.

- Advantages of processing scale: The vertical V grooving machine has more than ten independent pressure plates and more than ten independent clamps to actively clamp the board material. It is easy to process regardless of the size of the board, and can be grooved horizontally and vertically, with a workpiece of 80 * 80mm. The horizontal V grooving machine is only suitable for grooving large sheet When use horizontal CNC V grooving machine, after longitudinal grooving, the sheet material deforms and cannot be clamped horizontally, resulting in the inability to groove horizontally.

- Advantages of the Installation: The vertical V groove machineis welded from steel plates, with high strength and smooth and quiet operation. It can operate stably by placing the leveling device on a flat and sturdy cement floor, making it easy to move and lift. Due to the high-speed operation of the gantry, the horizontal groove machine has a large impact force, and the platform needs to be adjusted according to the installation diagram. Therefore, concrete foundations must be made according to the installation diagram, and large-scale construction must be carried out.

- Safety: Vertical V groove machinehave better safety than CNC horizontal V groove machine.

- Price: horizontal cnc v groove machine vs vertical v groove machine, horizontal type is cheaper.

Conclusion

Compared horizontal cnc v groove machine vs vertical v groove machine, different types of cnc v grooving machine have their own advantages. Horizontal type is suitable for grooving thin and large size sheet metal with cheaper price, and vertical CNC V grooving machine has advantages in speed, precision and cutting thickness. SC is a professional CNC V grooving machine manufacturer, please feel free to contact us for more information about the machine.