High Mast Light Poles Industry Background

Poles production lines can produce: High master street lights, road lights, monitoring poles, new shaped pipe lights, stainless steel landscape lights landscape lights, sculpture landscape lights, garden lights, cast aluminum garden lights, cast iron garden lights stainless steel garden lights, shaped garden lights, new shaped tubes Garden lights, iron lamps, spotlights, lawn lights,stainless steel lawn lights, outdoor wall lights, fireworks lights, etc.

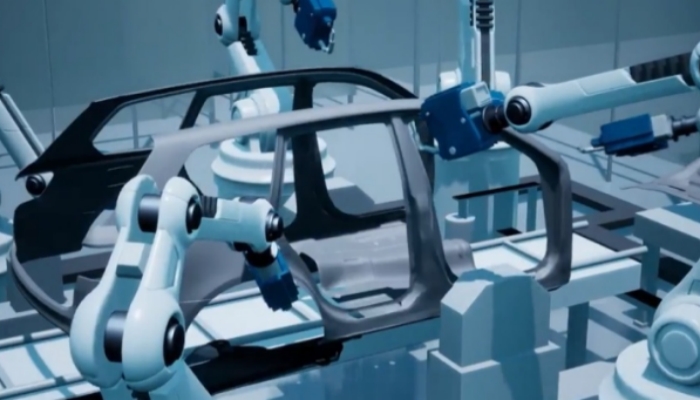

Production Process

The production process and necessary equipment for the production and manufacturing of common street lamp posts. Common street lamp posts refer to the common lighting lamp posts (cones) on the roadside. Its actual production process can be roughly divided into the following aspects:

- Uncoilding and leveling the coils, cut to length line and silting machine to cut the sheet plate. This process cut raw materials into a ladder shapethat prepare for the following bending.

- Large duty CNC press brake machine bends the sheet into a cylindrical shape. Customers can choose one big capacity press brake or tandem press brake. The length of ladder shaped raw materials is produced and manufactured according to customer regulations. Because the thickness of the raw materials used varies, clients usually selected CNC bending machines ranging from 160 tons to 1000 tons, with lengths ranging from 12 meters to 14 meters, and longer ones can be customized, such as 16 meters.

- Joint welding combines cylindrical gaps. Welding flanges and electrical doors, etc.Joint welding combines cylindrical gaps. This process is of course easy to explain, which involves bending sheet metal into cylindrical raw materials and carrying out joint welding. Fully automatic submerged arc welding machine, gantry type large-diameter argon arc welding machine.

- Straightening (deformation after welding) and elbows (not used for connecting auxiliary mechanical equipment). Straighten and bend. Straightening is essential as the welded pipes undergo certain deformations. Therefore, according to the customer’s requirements for the processing technology of road lamps, it is also possible to stipulate that the rod body sheet metal should be bent into a certain angle of view. If such regulations exist, it is essential to apply them to auxiliary mechanical equipment such as CNC pipe bending machines and straightening machines.

- Carry out polishing according to the electric polishing machine.

- Experience electrostatic induction electrostatic powder spraying automatic production line for surface painting or electroplating

- Equipped with the original electrical appliances.

Pain Points:

Manufacturers in the high mast pole industry require the use of large-scale cutting and bending equipment for high-strength operations every day and they need to reasonably layout workshop machines and improve production efficiency.

SC Poles Production Line Manufacturing Solution:

Cut to length line

The main task is to uncoiling, leveling, and cut the steel coil into the required size. The cut to length line consists of six parts: an uncoiler and side guide device, a leveling machine, a plate shearing machine, a material stacking row, and an electrical system. Especially suitable for street lamp poles, flagpoles, high mast poles producing to leveling and cut.

Steel plate slitting production line

Suitable for longitudinal shear processing of long shear plates, the length of the shear plate can be adjusted arbitrarily. With high labor productivity, the required cutting plate is pressed onto the walking device through hydraulic steel, and the disc cutter is rotated to cut the plate. The plate is cut along with the running of the walking device. When bending, the plate is placed diagonally according to the required size to cut the tapered plate. Especially suitable for cutting board materials for lamp poles and flagpoles.

SC SHENCHONG professional poles slitting machine has the automatic unloading and stacking device, which is convenient for workers to use a crane to transport a pile of longitudinally cut boards to the front of the bending machine.

Based on our rich experience in the high mast light poles production line manufacture, we highly recommend client to use the leveling machine to leveling the slit sheet, which can reduce the stress and get better bending results.

Tandem press brake machine

Tandem press brake consists of two cnc press brake machines, with dual stage linkage to achieve synchronous operation.

SC CNC tandem press brake equipped with different pole molds, which can be used for producing street lamp posts, flagpoles, high pole lights, etc. When used for producing conical lamp posts, a conical mold is installed, multiple blades are bent, one blade is bent in the middle, and one conical lamp post is formed. Then use a lamp pole rolling machine to pull out the lamp pole; When producing polygonal lamp posts, marker posts, and high pole lights, a specialized polygonal mold is installed, and multiple knives are bent. The middle knife is bent, and a multi deformation lamp post is formed. Then, the lamp post is pulled out using a rod winding machine.

Both SC heavy duty press brake and tandem press brake can optional assembly the front feeding, back feeding and side unloading device, which can help clients to easily bend the sheet plate.

Automatic seam welding production line

This device consists of a main body, a traction bed, and a feeding hood. The traction bed is moved by a moving car that pulls a clamp to hold the steel large head car, pushing the steel rod from the small head to the large head. It moves at a uniform speed under the six clamping jaws of the main body. The large end of the steel rod is automatically aligned by the guide wheel on the machine head under the hijacking of the loosened steel rod car. As the steel rod closes, the welding machine begins to undulate welding. This device adopts automatic welding and the flux is automatically recovered, The welding seam is uniform, continuous and beautiful, with strong penetration. The joint welding is formed in one go, and the welding efficiency is high. The speed is 23 meters/minute, which is three times that of gas shielded welding. The cost is lower than that of gas welding. It is currently the equipment in the China lamp pole industry with fast welding speed, good effect, and low price. This equipment is mainly used for welding street lamp poles and flagpoles. Large pole marker poles and high pole lights generally do not require this equipment. Large pole markers and high pole lights generally do not require this equipment.

Mechanical sewing machine

This machine is a specialized equipment suitable for sewing high pole lights and sign poles after bending. This machine is driven by a turbine and worm gear for joint action, which can be operated in linkage or single action. It is efficient when combined with manual welding. After spot welding and shaping, it can be welded on a semi-automatic welding production line. At the same time, it can round the marker posts and high pole lights.

Semi automatic welding production line

This machine does not emit light during welding, has a fast welding speed, and is suitable for various pole bodies. It is easy to adjust manually and quickly. The weld seam is uniform, continuous and beautiful, and has strong penetration. It can be formed in one go, with a speed of 1-3 meters/minute, which is three times that of gas shielded welding. It is a necessary equipment for marking poles and high pole lamp welding after mechanical sewing machines.

Steel pipe straightening machine

The device has a simple and compact structure, which is convenient. During specific operation, the steel rod can be manually placed on the compression mold, and there is a person holding it, holding it, and pressing the button. The straightness of steel poles is controlled by manual visual inspection, with high efficiency. This equipment can straighten any shape of street light poles, sign poles, flagpoles, and high pole lights, with the head rounded.

According to design requirements, the head of some street light poles needs to be bent, which is also a self bending arm street light pole composed of a main board and a bending mold. Equipped with two sets of molds, the straight mold is cleaned by the reducer, and the steel pipe pressed on the circular mold is bent along the circular mold. The operation is simple, and there is no need for heating or filling. The upper part of the tapered street lamp post can be directly bent, which is an economical and necessary equipment for street lamp post manufacturers