Table of Contents

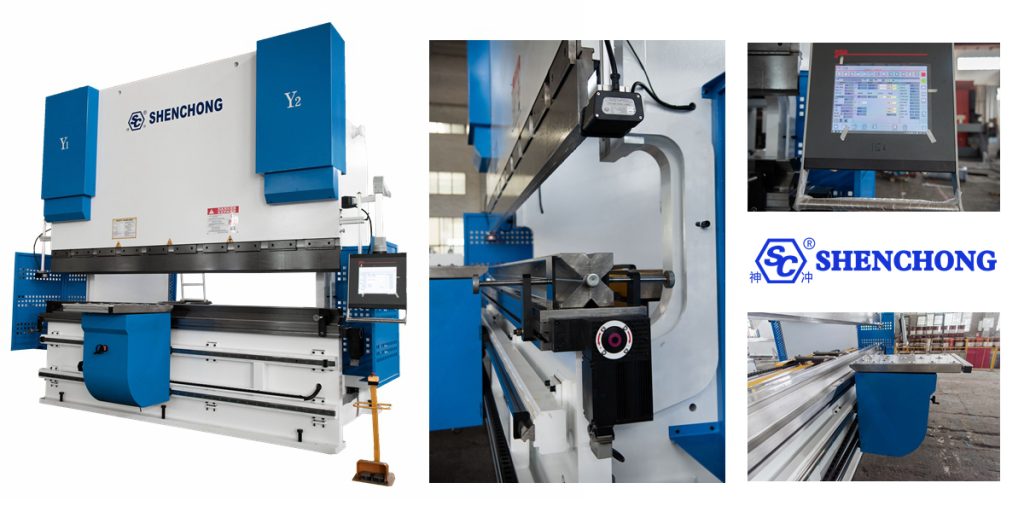

Germany CNC press brake WEK 400Ton 4000mm 6+1 Axis ESA S650W with MSD laser protection is a high-precision, large-tonnage bending equipment suitable for sheet metal processing, metal manufacturing, automotive, aerospace, construction and other industries. The equipment adopts 6+1 axis control, is equipped with ESA S650W control system, and is equipped with MSD laser protection to ensure efficient and safe bending operations.

1. Main technical parameters of Germany CNC Press Brake

Parameters | Specifications |

Brand/Model | SC WEK 400Ton 4000mm |

Bending force | 400 tons |

Bending length | 4000mm (4 meters) |

Number of control axes | 6+1 axes |

Control system | ESA S650W |

Safety protection | MSD laser protection |

Additional Configuration | With follow-up support device |

Stroke adjustment | Precise control, adaptable to different plates |

Hydraulic system | Efficient and energy-saving hydraulic system |

Body structure | High-strength steel plate welding, strong rigidity |

Back gauge system | Precise multi-axis control, automatic position adjustment |

Working accuracy | High-precision hydraulic synchronization technology to ensure bending accuracy |

2. Main features of German CNC bending machine

1) High-precision bending

- Adopt 6+1 axis CNC control to ensure high bending accuracy, suitable for complex bending needs.

- Adopt hydraulic synchronization technology to ensure synchronous operation of both sides of the slide to ensure bending consistency.

- The back gauge system supports multi-axis adjustment to provide more accurate positioning.

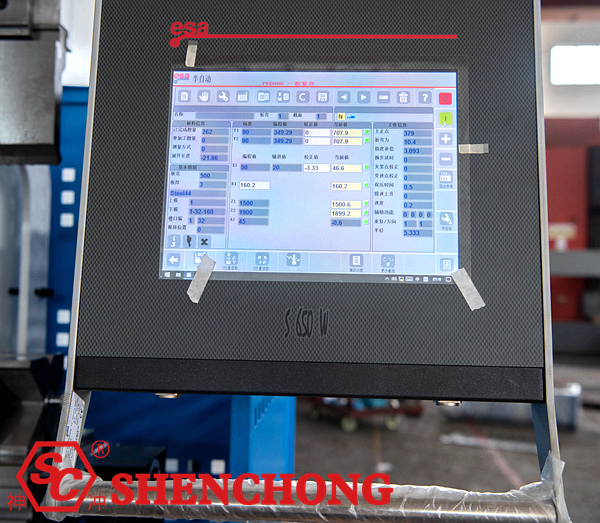

2) ESA S650W control system

ESA S650W control system technical parameter table:

ESA S650W is a high-performance CNC press brake machine control system designed for automated operation and intelligent management of bending machines. It combines advanced touch screen interface, 3D graphics programming, remote connection and precise bending control functions to greatly improve production efficiency and processing accuracy.

- Intelligent operation interface, visual programming, easy to learn and use.

- Support 3D graphics programming, can simulate the bending process, and reduce the trial time.

- Store a variety of bending processes, which can be quickly called to improve production efficiency.

- Networking function, can be linked with other production equipment, and supports remote monitoring.

Function | Description |

Operation interface | 15.6-inch full-color touch screen, intuitive and easy to use |

Operating system | Runs Linux or Windows CE, strong stability |

Bending programming | Supports 2D/3D graphic programming, automatic calculation of bending sequence |

Axis control | 6+1 axis control, precise positioning |

Intelligent computing | Automatic calculation of bending angle, back gauge position, mold compensation |

Remote networking | Supports Wi-Fi/Ethernet remote monitoring, program upload/download |

Storage capacity | Large-capacity storage, can store massive bending programs |

USB interface | Supports U disk import/export data |

Safety function | Compatible with MSD laser safety protection system |

Compatibility | Compatible with a variety of hydraulic systems and motor drive systems |

ESA S650W main functions:

① Full-color touch screen interface

- 6-inch high-resolution touch screen, intuitive operation.

- Graphical display of bending process, real-time feedback of bending status.

- Multi-language support (including Chinese, English, German, etc.), suitable for global users.

② Intelligent bending programming

- 2D/3D graphic programming: users can draw bending graphics directly on the screen, and the system automatically generates the bending sequence.

- Automatic calculation of bending compensation: automatic calculation of compensation value according to material thickness, mold parameters and bending angle to improve processing accuracy.

- Can store a variety of bending processes, convenient for repeated calls, and improve production efficiency.

③ Accurate axis control

6+1 axis synchronous control, support automatic adjustment of back gauge, improve bending accuracy.

Axis configuration:

- Y1/Y2: Control the synchronization of left and right cylinders to ensure bending accuracy.

- X axis: Control the back gauge to move forward and backward.

- R axis: Control the up and down adjustment of the back gauge.

- Z1/Z2 axis: Control the left and right movement of the back gauge.

- +1 axis (C axis): compensation function to improve bending consistency.

④ Remote networking and data management

- The device status can be remotely monitored through Wi-Fi/Ethernet connection.

- The USB interface supports bending program storage and import and export for easy process management.

- Compatible with MES/ERP system, it can be integrated with the enterprise production management system to improve the level of automation.

⑤ Safety and compatibility

- Support MSD laser protection system to prevent misoperation and improve operational safety.

- Compatible with hydraulic systems and servo motors of different brands, it can be used for various types of bending machines.

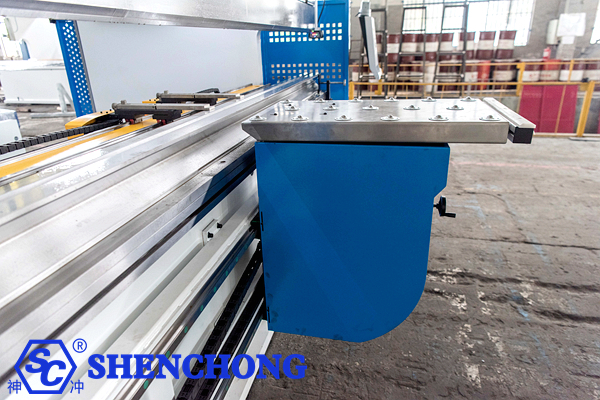

3) Bending follow-up support device

Function:

The follow-up support device of the bending machine is an auxiliary device, which is mainly used to support and follow the movement of the plate to prevent the plate from sagging, deformation or damage during the bending process.

It can adjust the height and angle synchronously with the movement of the slider of the bending machine to ensure that the workpiece always maintains uniform force during the bending process, improving the processing quality and production efficiency.

Main advantages:

① Prevent workpiece deformation and improve bending quality

- For large-sized or thin-plate workpieces, if there is no support device, the plate will sag due to its own weight, resulting in an uneven bending line, uneven angles, and even scratches or damage.

- The follow-up support device can automatically support the workpiece to prevent the bending accuracy from being affected by sagging due to its own weight.

② Reduce labor intensity and improve production efficiency

- When processing large-sized workpieces, operators usually need multiple people to assist in supporting the material, otherwise the plate is easy to shake and affect the processing accuracy.

- After using the follow-up support device, manual intervention can be reduced, the degree of automation can be improved, labor costs can be reduced, and production efficiency can be improved.

③ Adapt to various bending angles and workpiece types

- The support device can automatically follow the movement of the bending machine to adapt to different bending angles without manual adjustment.

- Suitable for large-format, irregular, and easily deformed sheet metal, such as stainless steel, aluminum, etc.

④ Reduce scratches on the workpiece surface

- When ordinary bending machines process thin plates or plates with surface treatment (such as coated plates, mirror stainless steel), scratches are easily caused by friction, sliding or collision.

- The follow-up support device uses a smooth support plate or roller support, which can effectively reduce friction and avoid scratching the workpiece surface.

⑤ Support intelligent control

- The follow-up support device of modern CNC press brakemachines can be linked with the CNC system to automatically adjust the support position and movement trajectory according to the bending parameters to ensure accurate bending.

- Suitable for intelligent production lines and support automated batch processing.

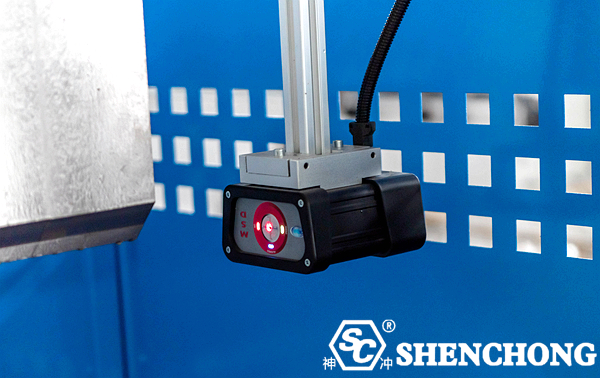

4) MSD laser protection system on Germany CNC press brake

The MSD laser protection system is an advanced safety protection device dedicated to CNC press brake machines to prevent operators from being injured due to misoperation during the bending process. The system uses laser scanning technology to detect in real time whether there are obstacles (such as the operator’s hands or foreign objects) in the bending area. If an abnormality is detected, the system will immediately stop the bending machine to ensure safe production.

- Adopt advanced laser safety protection to ensure the safety of operators.

- Automatically detect obstacles. If any abnormality is found, the machine can be stopped immediately to prevent accidents.

- Suitable for high-precision processing environments to improve safety and work efficiency.

Main technical features of MSD laser protection:

Function | Description |

Safety principle | Detect obstacles through laser scanning and monitor the slider area in real time |

Laser type | Multiple infrared laser beams for accurate object identification |

Reaction speed | Millisecond response time to ensure timely braking |

Detection area | Adjustable to adapt to different bending machines and workpiece sizes |

Integration method | Can be integrated with CNC systems such as ESA S650W |

Working mode | Automatic start and stop to avoid false triggering affecting production |

Environmental adaptability | Suitable for different lighting and industrial environments without interference |

Compatibility | Compatible with hydraulic press brakes and electro-hydraulic synchronous press brakes |

Introduction to the main functions of MSD laser protection:

① High-precision laser scanning

- Multiple laser beams are used to form a three-dimensional protection barrier to accurately monitor the area under the slider.

- When the workpiece enters the normal bending area, the system works normally without affecting production efficiency.

- When the operator’s hands, tools or other objects enter the danger zone, the system immediately triggers an emergency stop.

② Ultra-fast response time

- The response speed of the MSD system is less than 1 millisecond, far exceeding traditional grating protection, ensuring the safety of the operator.

- Cooperating with the hydraulic braking system of the bending machine, the slider movement is stopped in the shortest time.

③ Adjustable detection area

- Different laser protection ranges can be set according to the workpiece size and bending machine specifications.

- Adapt to the bending safety requirements of small precision workpieces and large heavy workpieces.

④ Intelligent automatic start and stop

- When the tool is replaced or not in working state, the system can automatically adjust to avoid false alarm triggering.

- The protection system can be manually or automatically turned off to meet special bending needs.

⑤ Compatible with a variety of CNC systems

- MSD laser protection can be seamlessly integrated into CNC systems such as ESA S650W, Delem, and Cybelec.

- Support linkage with the hydraulic and electronic control systems of the bending machine to ensure precise control.

⑥ Durable and stable

- Applicable to various industrial environments, not affected by dust, light, temperature changes and other factors.

- The laser module has a long life, low maintenance cost, and long-term stable and reliable operation.

5) High-efficiency and energy-saving hydraulic system

- Adopt hydraulic components imported from Germany to ensure stability and service life.

- Energy consumption optimization design, reduce operating costs, and reduce maintenance requirements.

6) Sturdy frame suitable for heavy-load bending

- The body adopts a high-strength steel plate welding structure, which is tempered to prevent deformation during long-term use.

- Suitable for bending processing of a variety of materials (such as carbon steel, stainless steel, aluminum alloy, etc.).

3. Shipping records

The Germany CNC press brake WEK 400Ton 4000mm 6+1 axis is a high-precision, high-safety, intelligently controlled CNC bending equipment suitable for large-scale, high-demand bending production. Its ESA S650W control system, MSD laser protection and precision hydraulic system make it highly competitive in the industry and suitable for enterprises to improve production efficiency and bending accuracy.