Brand: SC SHENCHONG

Model: QC11KQ front feeding plate shearing machine

CNC Controller: DELEM DA360T

Front Feeding Table Size: Customized

Price Range: $30000-$80000/Set

After Sale: 13 Months

Lead Time: 35-50 Working Day

QC11KQ front feeding plate shearing machine, also known as CNC front feeding shearing, automatic feeding shearing machine, as the name suggests, is a specialized CNC guillotine shear that works in conjunction with feeding device and replaces manual labor to transport plates for shearing processing.

The operation of SC QC11KQ front feeding plate shearing machine is simple and easy to learn, which can greatly improve production efficiency, save labor costs, and improve labor conditions. In the era of CNC intelligence, it is an indispensable and epoch-making CNC product for the development and growth of enterprises.

In the era of CNC intelligence, the CNC front feeding shearing machine, with its more intelligent characteristics, provides indispensable and epoch-making CNC support for the development of enterprises.

|

Model |

Plate Thickness(mm) |

Cutting Length (mm) |

Throat Depth (mm) |

Backgauge Stroke (mm) |

Cutting Angle |

Cutting times/min |

Main Motor(kw) |

Machine Size(mm) |

|

4×2000 |

4 |

2000 |

80 |

600 |

0.5°~2° |

14 |

5.5 |

2600×1680×1750 |

|

4×2500 |

4 |

2500 |

80 |

600 |

0.5°~2° |

14 |

5.5 |

3125×1750×1765 |

|

6×2500 |

6 |

2500 |

80 |

750 |

0.5°~1°30′ |

14 |

7.5 |

3150×1840×1960 |

|

6×3200 |

6 |

3200 |

80 |

750 |

0.5°~1°30′ |

12 |

7.5 |

3850×1840×1995 |

|

6×4000 |

6 |

4000 |

80 |

750 |

0.5°~1°30′ |

10 |

7.5 |

4650×1840×2100 |

|

6×5000 |

6 |

5000 |

80 |

750 |

0.5°~1°30′ |

8 |

7.5 |

5650×2050×2400 |

|

6×6000 |

6 |

6000 |

80 |

750 |

0.5°~1°30′ |

8 |

7.5 |

6650×1980×2380 |

|

8×2500 |

8 |

2500 |

80 |

750 |

0.5°~2° |

14 |

7.5 |

3135×1840×2075 |

|

8×3200 |

8 |

3200 |

80 |

750 |

0.5°~2° |

12 |

7.5 |

3850×1990×2050 |

|

8×4000 |

8 |

4000 |

80 |

750 |

0.5°~2° |

10 |

7.5 |

4650×1890×2075 |

|

8×5000 |

8 |

5000 |

80 |

750 |

0.5°~2° |

7 |

15 |

5650×2050×2400 |

|

8×6000 |

8 |

6000 |

100 |

750 |

0.5°~2° |

7 |

15 |

6805×2115×2715 |

|

10×2500 |

10 |

2500 |

100 |

750 |

0.5°~2°30′ |

10 |

15 |

3195×1915×2205 |

|

10×3200 |

10 |

3200 |

100 |

750 |

0.5°~2°30′ |

8 |

15 |

3895×1900×2235 |

|

10×4000 |

10 |

4000 |

100 |

750 |

0.5°~2°30′ |

6 |

15 |

4695×1970×2450 |

|

10×5000 |

10 |

5000 |

100 |

750 |

0.5°~2°30′ |

5 |

15 |

5700×2115×2715 |

|

10×6000 |

10 |

6000 |

100 |

750 |

0.5°~2°30′ |

5 |

15 |

6905×2115×2800 |

|

12×2500 |

12 |

2500 |

100 |

750 |

0.5°~2°30′ |

10 |

15 |

3195×2000×2210 |

|

12×3200 |

12 |

3200 |

100 |

750 |

0.5°~2°30′ |

8 |

15 |

3895×1950×2240 |

|

12×4000 |

12 |

4000 |

100 |

750 |

0.5°~2°30′ |

6 |

15 |

4710×1950×2485 |

|

12×5000 |

12 |

5000 |

100 |

750 |

0.5°~2°30′ |

5 |

30 |

5750×2115×2800 |

|

12×6000 |

12 |

6000 |

100 |

750 |

0.5°~2°30′ |

5 |

30 |

7150×2300×3100 |

|

16×2500 |

16 |

2500 |

100 |

750 |

0.5°~2°30′ |

8 |

15 |

3215×1970×2340 |

|

16×3200 |

16 |

3200 |

100 |

750 |

0.5°~2°30′ |

7 |

15 |

3915×1970×2455 |

|

16×4000 |

16 |

4000 |

100 |

750 |

0.5°~2°30′ |

6 |

15 |

4715×2010×2590 |

|

16×5000 |

16 |

5000 |

100 |

750 |

0.5°~3° |

5 |

22 |

6000×2300×3000 |

|

16×6000 |

16 |

6000 |

100 |

750 |

0.5°~3° |

5 |

37 |

7250×2400×3100 |

|

20×2500 |

20 |

2500 |

100 |

750 |

0.5°~3° |

6 |

22 |

3235×2020×2465 |

|

20×3200 |

20 |

3200 |

120 |

750 |

0.5°~3° |

5 |

30 |

4150×2065×2755 |

|

20×4000 |

20 |

4000 |

120 |

750 |

0.5°~3° |

4 |

30 |

4955×2125×2885 |

|

20×5000 |

20 |

5000 |

120 |

750 |

0.5°~3° |

4 |

37 |

6000×2300×3050 |

|

20×6000 |

20 |

6000 |

120 |

750 |

0.5°~3° |

5 |

37 |

7150×2450×3280 |

|

25×2500 |

25 |

2500 |

120 |

750 |

0.5°~3.5° |

5 |

37 |

3465×2130×2710 |

|

25×3200 |

25 |

3200 |

120 |

750 |

0.5°~3.5° |

5 |

37 |

4120×2200×3000 |

|

25×4000 |

25 |

4000 |

120 |

750 |

0.5°~3.5° |

4 |

37 |

4950×2200×3150 |

|

30×2500 |

30 |

2500 |

120 |

750 |

0.5°~3.5° |

4 |

37 |

3465×2170×2770 |

|

30×3200 |

30 |

3200 |

120 |

750 |

1°~3.5° |

3 |

37 |

4200×2300×3200 |

|

40×2500 |

40 |

2500 |

80 |

750 |

1°~4° |

4 |

37×2 |

3770×2550×3400 |

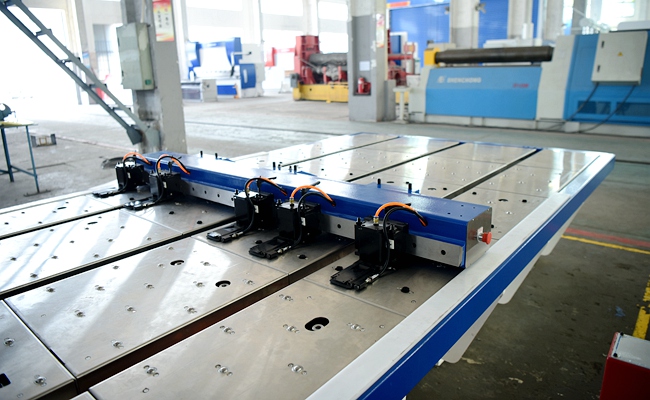

The front feeding frame uses a steel structure and is tempered to eliminate internal stress, rigidity and stability.

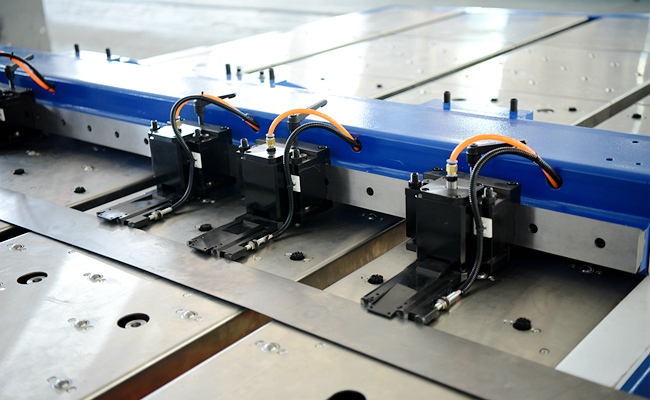

The front feeding adopts imported precision ball screw drive, linear guide rail guidance, and digital AC servo motor drive.

Accurate positioning, fast and stable operation, with steel balls and brushes arranged alternately on the front feeding table.

Automatic unloading the finished workpiece and has the waste box.

SC SHENCHONG is a professional front feeding CNC shearing machine manufacturer, we can not only produce the single unit shearing machine, but also produce the automatic shearing production line for clients.

Front feeding plate shearing machine usually need to be customized based on the clients’ cutting requirements, and the price range can be large. Every customer can obtain a direct quotation for front feeding shearing machines from us. Shenchong is the most famous front feeding shearing machines manufacturer in China, and we can provide you with detailed technical solutions and prices. Please provide us with your material type, maximum thickness, and maximum length.

Yes, Wuxi Shenchong is a reliable sheet metal automatic hydraulic front feeding shearing machines supplier with complete export experience. All of our machines provide installation services. We dispatch technical personnel to the customer’s factory for machine installation and pre operation. (Customers only need to pay for airfare and hotel expenses)

We provide detailed machine user manuals and training videos, or customers can have video calls with our sales and engineers. Our technicians can provide training on how to use our machines for your factory. The buyer needs to bear the airfare cost. You can also send your technical personnel to our company to learn how to operate the machine.

Of course. We have produce front feeding plate shearing machine over 20years, and we different front feeding shearing machine cases that can show you. SC looks forward to your arrival! Welcome to visit our factory and inspect the quality of the feeding and shearing machine on site.

After you confirm the visit time, please inform us in advance. Then we will pick you up at the airport or train station on time. Any issues will be resolved on-site as soon as possible.

In addition, if you would like to visit our shearing machine factory online, you can contact our sales personnel and they will arrange a video call with you.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.