Table of Contents

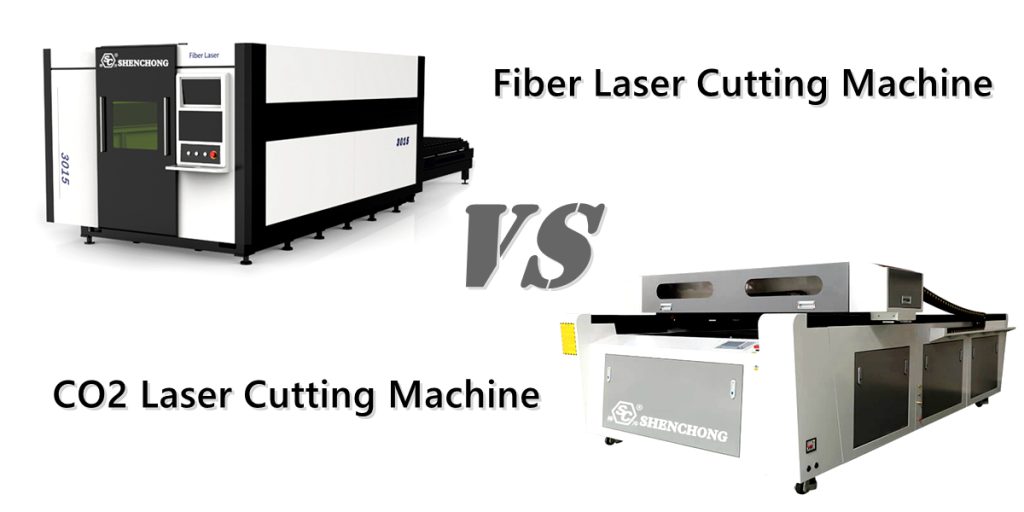

Fiber laser cutting machine and CO2 laser cutting machine are two common industrial laser cutting equipment. They have obvious differences in light source, applicable materials, cutting speed, energy consumption, maintenance cost, etc. The following is a detailed comparison.

1. Fiber laser cutting machine VS CO2 laser cutting machine: working principle

The working principles of CO2 laser cutting machine and fiber laser cutting machine are obviously different, mainly reflected in the laser generation method, beam transmission method, wavelength, energy conversion efficiency and other aspects.

Working principle of fiber laser cutting machine:

(1) Laser generation

Rare earth-doped (such as ytterbium) fiber is used as the laser medium, and the optical signal is amplified through optical pumping technology to generate a high-energy laser beam.

The main wavelength is 1.06μm (near-infrared light). This wavelength has a high absorption rate for metal materials, so it is suitable for cutting metal materials such as carbon steel, stainless steel, aluminum, copper, brass, and titanium.

(2) Beam transmission

Fiber laser does not require a reflector, but is transmitted through a flexible optical fiber. It can be directly transmitted to the cutting head without the need for additional optical alignment equipment.

Due to the extremely low transmission loss of optical fiber, the cutting efficiency is higher and the energy utilization rate is better.

(3) Cutting process

The focused fiber laser beam irradiates the metal surface, quickly melting and vaporizing the material.

With the help of high-pressure auxiliary gas (oxygen, nitrogen, air), the slag is blown away to improve the cutting speed and quality.

It is suitable for high-precision metal cutting, with fast cutting speed, small heat-affected zone, and almost no burrs.

Working principle of CO2 laser cutting machine:

(1) Laser generation

CO2 gas (main components: carbon dioxide, nitrogen, helium) is used as the laser medium, and high voltage electricity is used to excite CO2 gas to generate a laser beam.

The main wavelength is 10.6μm (far infrared light), which has a high absorption rate for non-metallic materials, so it is particularly suitable for cutting non-metallic materials such as wood, plastic, acrylic, leather, rubber, cloth, etc.

(2) Beam transmission

CO2 laser beam cannot be transmitted through optical fiber, but relies on reflectors and lenses to guide the beam and finally focus on the surface of the material for cutting.

Due to the use of lenses and reflectors, the equipment has high requirements for optical alignment, and the optical devices need to be maintained and replaced regularly.

(3) Cutting process

The focused CO2 laser beam irradiates the surface of the material, causing the material to absorb the laser energy and heat to the temperature of melting or vaporization.

With auxiliary gas (oxygen, nitrogen, air), the melt or oxide is blown away to achieve precise cutting.

Applicable to non-metallic and some metallic materials (metals have high reflectivity and CO2 laser energy utilization is low).

Comparison and summary of working principles:

Type | CO₂ laser cutting machine | Fiber laser cutting machine |

Laser wavelength | 10.6μm (far infrared) | 1.06μm (near infrared) |

Laser medium | CO₂ gas discharge excitation produces laser | Rare earth element-doped fiber amplified laser |

Beam transmission method | Transmitted through reflectors | Directly transmitted through optical fiber |

Application range | Suitable for non-metallic materials and some metal materials | Mainly used for metal cutting |

- CO₂ laser generates laser light through gas discharge, and the beam is transmitted by lenses and reflectors, which is suitable for non-metallic materials.

- Fiber laser uses optical fiber transmission and has no reflectors, which is suitable for high-precision metal processing.

2. Comparison of applicable materials

Applicable materials for CO₂ laser cutting machines:

- Non-metal materials: wood, acrylic, plastic, cloth, leather, rubber, glass, ceramics, paper, etc.

- Some metals (require coating or oxygen assistance): carbon steel, stainless steel, aluminum alloy (lower efficiency).

Applicable materials for fiber laser cutting machines:

- Metal materials (high cutting efficiency): carbon steel, stainless steel, aluminum, copper, brass, titanium, etc.

- Not suitable for non-metals (due to the low absorption rate of the wavelength 1.06μm, wood, plastic, glass, etc. are difficult to cut).

Comparison table of applicable materials:

Material Type | CO₂ laser cutting machine | Fiber laser cutting machine |

Carbon Steel | Can cut (slower, requires oxygen) | Best choice (fast speed, high cutting quality) |

Stainless Steel | Can cut (requires nitrogen or oxygen) | Best choice (fast cutting speed, no burrs) |

Aluminum | Can cut (requires high-power laser) | Can be cut (but easy to reflect, high power required) |

Copper | Difficult to cut (high reflectivity) | Can be cut (high power laser required) |

Brass | Difficult to cut (high reflectivity) | Can be cut (high power laser required) |

Titanium Alloy | Can cut (but slow) | Suitable for cutting |

Galvanized Steel | Can cut (requires nitrogen) | Can be cut (avoid oxidation) |

Wood | Best choice | Not suitable |

Acrylic | Best choice (smooth cut) | Not suitable |

Plastic | Can cut | Not suitable |

Leather | Can cut | Not suitable |

Cloth | Can cut | Not suitable |

Rubber | Can cut | Not suitable |

Glass | Cannot cut (surface engraving is possible) | Cannot cut |

Why are CO2 and fiber lasers suitable for different materials?

(1) Laser wavelength affects material absorption rate

Fiber laser wavelength: 1.06μm (near infrared light)

- Metallic materials (such as carbon steel, stainless steel, aluminum, copper) have high absorption rate for 1.06μm light, so the cutting speed is fast and the cut quality is high.

- Non-metallic materials (such as wood, plastic, acrylic) have low absorption rate for 1.06μm light, so they cannot be effectively cut.

CO2 laser wavelength: 10.6μm (far infrared light)

- Non-metallic materials (such as wood, acrylic, plastic, leather, cloth) have high absorption rate for 10.6μm light, so the cutting effect is good.

- Metallic materials (such as copper, aluminum, stainless steel) have high reflectivity for 10.6μm light, resulting in low energy utilization and slow cutting speed.

(2) High reflectivity of metal

Highly reflective metals such as copper and aluminum have high reflectivity for CO2 lasers, which can easily damage the laser and require coating or high-power laser for cutting.

Fiber lasers are easier to cut due to their shorter wavelength and higher energy density.

Summary of applicable materials for fiber laser cutting machine VS CO2 laser cutting machine:

- CO₂ laser is suitable for non-metal processing, such as advertising, clothing, packaging, woodworking, handicrafts and other industries.

- Fiber laser is suitable for metal processing, such as sheet metal processing, automobile manufacturing, aerospace, hardware processing, etc.

3. Cutting efficiency & speed

Cutting efficiency comparison table:

Comparison items | CO₂ laser cutting machine | Fiber laser cutting machine |

Cutting speed (thin metal) | Slow (fiber laser is 2-3 times faster) | Fast, suitable for high-speed cutting |

Cutting thickness (steel) | Can cut ≤20mm (high power) | Can cut ≤50mm (high power) |

Energy conversion rate | 10%-15% | 30%-50% |

Cutting accuracy | Higher (0.1mm) | Higher (0.05mm) |

- Thin metal materials (such as stainless steel, carbon steel ≤ 10mm): Fiber laser cutting speed is faster. Fiber laser cutting speed is 2-3 times faster than CO₂.

- Thick metal materials (>20mm): CO₂ and fiber laser can be used, but fiber laser has lower energy consumption. Fiber laser cutting is more efficient and has higher energy utilization.

- Non-metallic materials (such as acrylic, wood): CO₂ laser is more suitable, and fiber laser can hardly cut.

- CO₂ laser has a fast cutting speed on non-metals, but it is far inferior to fiber laser on metals.

Performance comparison table:

Item | CO₂ laser | Fiber laser |

photoelectric conversion efficiency | 10%-15% | 25%-35% |

Cutting Speed (Sheet Metal) | Slow | Fast |

Light beam quality | Good | Better |

Area | Large | Small |

Ease of use | Average | Good (high automation) |

4. Cutting quality

Cutting quality comparison table:

Comparison items | CO₂ laser cutting machine | Fiber laser cutting machine |

Incision quality | Smooth cut (especially non-metal) | The metal cutting edge is smoother |

Heat affected zone (HAZ) | Large (10.6μm wavelength absorption is deeper) | Small (1.06μm wavelength has high absorption rate) |

Assist gas | Requires (oxygen, nitrogen, air) | Requires (oxygen, nitrogen) |

- CO₂ lasers have smooth edges when cutting non-metals, but are prone to burrs when cutting metals, which require post-processing.

- Fiber lasers have better cutting quality for metal materials, with clean edges and a small heat-affected zone.

5. Equipment Cost & Maintenance

Fiber laser cutting machine VS CO2 laser cutting machine cost comparison table:

Comparison items | CO₂ laser cutting machine | Fiber laser cutting machine |

Equipment cost | Low (suitable for small businesses) | Higher (but low long-term operating cost) |

Operation energy consumption | High (10-15% energy efficiency) | Low (30-50% energy efficiency) |

Core components | Laser tube, reflector, lens | Fiber laser source, cutting head |

Maintenance cost | High (laser tube and lens need to be replaced regularly) | Low (long life of fiber laser source) |

Service life | Laser tube: 8000-10000 hours | Fiber laser source: >100,000 hours |

- CO₂ laser equipment has a low initial investment, but high operating costs, and requires regular replacement of consumables such as laser tubes, reflectors, and lenses.

- Fiber lasers have a high initial investment, but low maintenance costs and a long lifespan, making them more suitable for long-term industrial production.

6. Environmental protection & safety

Environmental protection and safety comparison table:

Comparison items | CO₂ laser cutting machine | Fiber laser cutting machine |

Environmental protection | Smoke exhaust equipment is required (non-metal processing produces smoke and dust) | More environmentally friendly (no carbonization, less smoke and dust) |

Laser safety | 10.6μm laser is not easy to penetrate the skin and is safer | 1.06μm laser can penetrate the eyes, so protective glasses are required |

- CO₂ laser processing of non-metals produces smoke and dust, which requires an additional smoke exhaust system.

- Fiber lasers are more dangerous to the eyes, and operators must wear special laser goggles.

7. How to choose: CO₂ laser cutting machine or fiber laser cutting machine?

Choose a CO₂ laser cutting machine if you need:

- Processing non-metallic materials (wood, plastic, acrylic, leather, cloth)

- Small business or limited budget (lower equipment cost)

- Need to take into account both cutting and engraving (advertising, handicrafts, packaging industry)

Choose a fiber laser cutting machine if you need:

- Professional metal processing (carbon steel, stainless steel, aluminum, copper, etc.)

- High efficiency & high precision (industrial production, sheet metal processing)

- Long-term operation & low maintenance cost (long life of fiber laser source)

Recommended usage scenarios:

Scenarios | Recommended equipment |

Non-metal processing (such as wood, acrylic) | CO₂ laser |

Precision metal processing, sheet metal factories, auto parts | Fiber laser |

Cutting of large quantities of thin metal plates | Fiber laser |

Comprehensive small factories, education and scientific research | Depends on budget and material type |

Summary:

Comparison items | CO₂ laser cutting machine | Fiber laser cutting machine |

Applicable materials | Non-metal, some metals | Mainly metal |

Cutting speed | Slow (especially metals) | Faster (especially thin metals) |

Cutting thickness | ≤20mm | ≤50mm |

Equipment cost | Low | High |

Maintenance cost | High (need to replace laser tube) | Low (long life of fiber laser source) |

- CO₂ laser cutting machine: suitable for cutting non-metallic materials and light metal processing, mature technology, but high energy consumption and high maintenance cost.

- Fiber laser cutting machine: suitable for efficient metal cutting, especially thin plates and high-reflective materials, high efficiency, low energy consumption, simple maintenance, and is the mainstream of future development.