What is plate shearing machine precision? Plate shearing machine precision is the cutting accuracy of the plate shearing machine, and it is the most important factor to evaluate the quality of the plate shearing machine. For this reason, to ensure the plate shearing machines has high cutting precision is the most critical task for manufacturers and the buyers also need to understand the factors that affect the shearing machine cutting accuracy. This article will introduce the accuracy standard of shearing machine in China and the factors that affect the plate shearing machine precision.

What is Plate Shearing Machine?

Plate shearing machine is an important sheet metal processing machinery, which mainly used for cutting metal sheet plate. It can cut metal sheets according to a certain size and shape, and it is one of the essential cutting equipment in the metal processing industry.

Plate shearing machine cuts metal sheets through hydraulic shearing force. The shearing force of a hydraulic plate shearing machine is generated by the interaction between the cutting edge and the cutting table. The cutting edge is located at the top of the plate shearing machine; the cutting table is located at the bottom, and the metal sheet is sandwiched between the two. By pressing down with the upper cutting edge, the metal sheet is pressed onto the cutting table, while generating a shear force to divide the metal sheet into the desired shape and size. During the whole shearing process, all the machine parts generate the shear force affects the plate shearing machine precision.

Plate Shearing Machine Precision

China have established a national standard for the accuracy of plate shearing machines. This standard is drafted in accordance with the rules given in GB/T 1.1-2009 “Guidelines for Standardization Work Part 1: Structure and Writing of Standards”, which replaces GB/T14404-1993 “Precision of shearing machines”.

Cutting Accuracy Standards For Chinese Shearing Machines

Level I standard: shear straightness ≤ 0.15mm/m, parallelism ≤ 0.10mm/m.

Level II standard: straightness 0.15mm/m ≤ δ≥ 0.30mm/m, parallelism 0.10mm/m ≤ δ≥ 0.20mm/m.

Above shearing precision standard is the Chinese national standard, which means it is the lowest accuracy standard for CNC shearing machines in China. If the hydraulic plate shearing machine does not meet this standard, the machine is unqualified.

Factors Affect Plate Shearing Machine Precision

Plate shearing machine precision is a key factor restricting its production efficiency and product quality, and continuously improving its cutting accuracy has become a necessary trend for shearing machine industry development. Below are the factors that can affect the shearing accuracy.

1. Poor Cutting Effect Caused By Human Operation

Sometimes, operators do not carefully check the instructions before installing the shearing machine blades, and start cutting directly without adjusting the blades after installation, which leads to poor cutting effect of the hydraulic CNC plate shearing machine. This case, operators should follow the standard of instruction to check the installation of shearing blades.

2. Quality Issues With The Sheet Plate Itself

Material have a significant impact on the accuracy of sheet cutting dimensions. The impurity of raw materials can lead to impurities and defects inside the sheet metal plate, thereby affecting the dimensional accuracy during the shearing process. Meanwhile, the properties of different materials in the shearing process are also different, such as hardness, strength, etc., which can affect the accuracy of shearing dimensions.

It is worth noting that the grain of the metal sheet also affects the cutting of the plate shear machine. During the steel plate production process, the steel plate will have patterns at the microscopic level. When cutting along the grain of the sheet plate, the cutting effect is good. When shearing perpendicular to these patterns, burrs are prone to appear on the cutting section.

3. Plate Shearing Machine Problems

When CNC plate shearing machine produced by the manufacturer with bad quality, for example, the blade clearance is too large, the blade holders are damaged, and some blade holders are not securely installed, all these machine problems can cause the terrible shearing results.

3.1 Blade Clearance

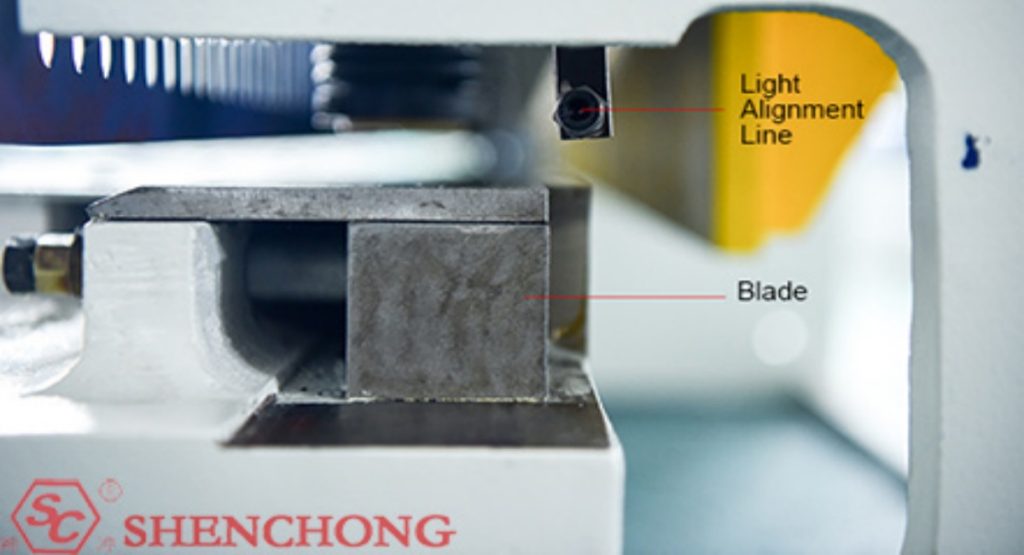

Blade clearance is an important factor in the shearing process. Blade clearance refers to the distance between the cutting edges, that is, the distance between the curved or straight edge and the corresponding pressure cutting edge.

The blade clearance of the shearing machine needs to be adjusted according to the thickness of the sheet metal plate. If the blade clearance is too large, it will cause deformation or compression of the metal plate during cutting, thereby affecting the cutting accuracy and precision. If the blade clearance is too small, it can make the shearing blades vulnerable to damage and may even cause the machine to shut down. Therefore, adjusting the blade clearance correctly is crucial for ensuring normal operation and accuracy.

3.2 Hold Down Oil Cylinder

Hold down oil cylinders can also affect the cutting result of the shearing machine. The installation and layout of the hold down oil cylinder need to be designed based on the pressure generated by the shearing of the sheet metal. If the density of the arrangement is incorrect, it will cause displacement of the sheet metal during the shearing process, thereby affecting the shearing accuracy.

3.3 Anti-Twist Device

When cutting sheet narrow edges, it is easy to cause distortion of the sheet metal plate due to the blade angle. To avoid distortion, operator needs to adjust the blade clearance according to the different thicknesses of the workpiece when he cut the narrow edges.

Another way to avoid the distortion is to use the plate shearing machine with anti-twist device. Anti-twist device on the plate shearing machine is specially designed to shear the narrow side of sheet plate.

3.4 Pneumatic Support Device

When shear the long and thin sheet plate, if there is no support device to hold the plate, the shearing result would be bad. Pneumatic support on the plate shearing machine is designed for long and thin plate cutting, which can hold the plate and ensure the cutting accuracy.

3.5 Shearing Speed

The cutting speed of the plate shear machine mainly affects the cutting effect as follows:

- The faster the shearingspeed, the shorter the time it takes to cut the sheet plate, and the higher the work efficiency. The same processing volume can save more labor costs.

- During the operation of the plate shearing machine, the faster the speed, the less compression on the sheet metal plate, the fewer burrs on the plate, and thus the higher plate shearing machine precision. The highprecision CNC shearing machine can achieve an accuracy of 0.02-0.03 millimeters/meter.

- During the rapid cutting process, a faster speed can reduce the time for blade extrusion wear, improve blade service life, and save usage costs.

By using high speed plate shearing machine, operators can get better cutting results.

Improve Plate Shearing Machine Precision

In actual production, the following measures can be taken to improve the accuracy of the shearing machine:

- Optimize shearing machinestructure: optimize the structure of the shearing machine, strengthen rigidity, reduce vibration, and thereby improve its accuracy.Also the shearing machine can assembly the anti-twist device or pneumatic support device if operators need to cut the narrow edges or cut thin and long plate. Besides that, if the user has enough budget, purchasing a high speed plate shearing machine is a good choice.

- Choose highquality materials: Choosing high-quality sheetplate as the raw material for cutting and adopts suitable blade materials can reduce errors generated during the processing. For example, if the user wants to cut stainless steel plate, as the professional shearing machine factory, we recommend to use blade material of Cr12MoV. To cut the mild steel plate, we recommend to use blade material of 6CrW2Si.

- Strengthen maintenance: Regularly maintain the hydraulic shearing machine, including regular cleaning and lubrication, to keep the equipment running in optimal condition.

- Use high-precision CNC controller: By using high-precision CNC system, the guillotine shear machinecan be more precisely controlled, thereby improving machining accuracy.

Conclusion

Even though compared with fiber laser cutting machine, plate guillotine shear is not the most popular cutting machine in the market, it still has its own advantages so that has large mount of users. Users need to understand the factors that affect the plate shear machine cutting accuracy. This article introduce the human operation, sheet metal material condition, and machine configurations can affect the cutting results, and also provide the solutions.