Electrical Cabinet Industry Background

The chassis and cabinet refer to the boxes and cabinets processed by sheet metal processing equipment (such as laser cutting machines, foaming machines, CNC punching machines, bending machines, etc). SC SHENCHONG provides sheet metal processing machinery solutions for Electrical cabinet industry, which are widely applicable in various fields.

The electrical cabinet is made of steel and is used to protect the normal operation of components. The manufacturing materials of electrical cabinets are usually divided into hot-rolled steel plates and cold-rolled steel plates. Cold rolled steel plates are softer than hot-rolled steel plates and more suitable for producing electrical cabinets.

The development and innovation of the chassis and cabinet industry in recent years are evident, from the square and traditional appearance to today’s trendy and dazzling appearance, and then to various personalized chassis appearances, it can be seen that designers have put a lot of effort into it.

The Complete Machine For Producing Electric Cabinet Or Panel

- CNC Fiber Laser Cutting Machine

- CNC Hydraulic Guillotine Shear Machine

- CNC Turret Punching Machine

- CNC Press Brake Machines( or Panel Bender Machine)

- Fiber Laser Welding Machines

- Riveting Press Machine

- Painting Machine

Pain Point:

The quality of the chassis and cabinet is directly affected by the quality of the manufacturing process. The steel plate edges of the chassis with higher technology will not have burrs, sharp edges, burrs, and other phenomena. Moreover, the exposed edges and corners are processed by folding, which is not easy to scratch the hands of the installer. The positioning of each card slot is also proportional and accurate, avoiding the embarrassing situation of parts not being installed or misplaced.

Solution

Fiber Laser Cutting Machine

The processing batch of cabinet sheet metal parts is large, and the labor intensity is high, we recommend SCDM Double Exchange Table Sheet Fiber Laser Cutting Machine.

High cutting quality: minimal burrs, low roughness, better cutting quality and verticality.

CNC Turret Punch Press

Plate punching machine is another method of cutting holes in the sheet metal industry, which uses a metal punch to impact the sheet metal and drill holes. It is suitable for large-scale production. When encountering regular shapes such as round holes and porous holes, CNC turret punching machines can quickly achieve stamping using molds. The chassis and cabinet usually require the use of a punch to punch out different pattern styles.

Bending

Due to the complexity of bending, this may be the most difficult step in the metal manufacturing of chassis and cabinet sheet metal processing, and engineers must be very familiar with the bending properties of the metal.

CNC Press Brake Machine

Generally, thin plates are used for bending chassis and cabinets, and using CNC press brake machines with a weight of less than 100 tons is a common choice.

Panel Bending Center

Manufacturers of chassis and cabinets who pursue bending efficiency will also choose automatic panel bender to replace CNC press brake when confirming the appropriate bending process.

Welding Machine

Welding process is based on the production nature, drawings, and technical requirements of the product, combined with existing conditions, to weld the cut and bent sheet metal parts into a box.

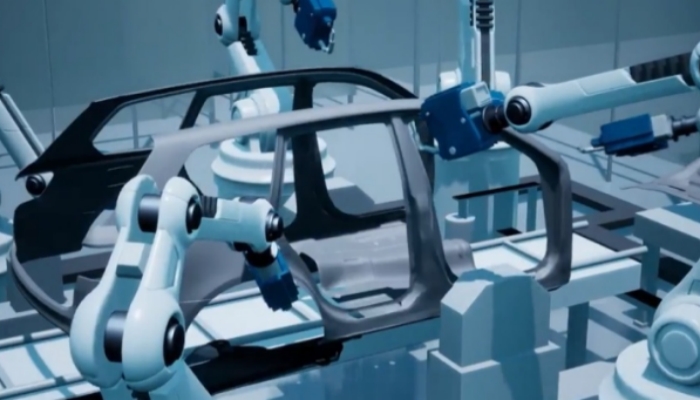

Automated production line for chassis and cabinets - solutions

With the increasing cost of labor and the standardization of safety protection regulations, more and more chassis and cabinet manufacturers are planning to use automated sheet metal production lines to improve production efficiency and reduce costs.

Basic configuration of automated sheet metal production line for chassis and cabinet:

- Intelligent sheet metal storage warehouse + automatic feeding + laser cutting machine + automatic cutting, automatic sorting, automatic loading and unloading with CNC turret punching press + robot press brake

- Uncoiling and leveling laser cutting machine + automated truss loading and unloading system + CNC turret punch press + panel bender + robot welding machine