16x2500 4 Roller Plate Bending Roll For Sale

16x2500mm 4 roller plate bending roll has the pre-bending function of the plate end and the CNC rolling function. It can feed the metal plate at a time, and can complete the pre-bending and the roll forming of the workpiece without turning the head.

The upper working roll of the machine is the main drive roll, and the lower roll and both sides of the roll are hydraulically driven. The lift displacement is controlled by the computer and is automatically leveled. The screen display shows the synchronization accuracy of ±0.1mm. The tilting and resetting of the rollover bearing body is hydraulic transmission, the balance of the upper roll is equipped with a balance mechanism, which can easily take out the rolled workpiece. It has a mobile stand-alone console that can be moved at any time; the machine is equipped with a safety interlocking device and is safe.

Due to its full-featured, high-precision, and easy-to-use operation, this device is the ideal contemporary CNC coiling device. It is the ideal model for rolling circular and arc-shaped workpieces in energy, transportation, petroleum, chemical, boiler, shipbuilding, hydropower, and metal structure industries.

16x2500 4 Roller Plate Roll Bending Machine Main Structure

Working Rolls

One of the most important components of the plate rolling machine, its quality and performance has a direct impact on the service life of the rolling machine and the precision of rolling.

Material Of Working Rolls

Working rolls are made of high-strength high-quality steel 42CrMo material, after forging, roughing, quenching and tempering, HB240 ~ 300, finishing after the intermediate frequency quenching HRC47-58, according to JB/ZG4289-86 roll steel standards, the stiffness is consistent (1/700 ~1/1000) L. L——The distance between the centerlines of the sides rack. And strictly in accordance with the working process of manufacturing all the standard roll manufacturing, to ensure its comprehensive mechanical properties.

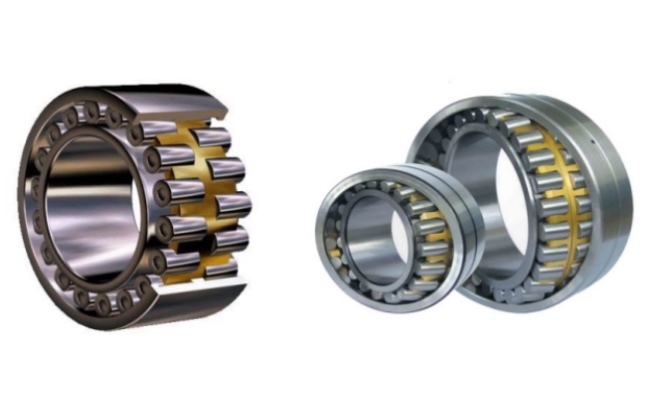

Bearing At Both Ends Of The Working Roll

The four-roll rolling machine adopts very durable double-row self-aligning roller bearings recommended by the industry for each roller.

Rack And Base

The base and frame are the main parts of the 16x2500mm 4 roller plate bending roll. SC Machinery selects high-quality steel, uses CNC cutting, grinding and welding, and then sends the welded structural parts to the professional heat treatment factory for stress relief annealing—CNC lathe machining, eliminating welding stress, so that it has enough strength and stiffness, to ensure normal operation at full load. All records of the workpiece are included in the quality tracking system.

Hydraulic System

The micro-control system includes the main electrical cabinets, control cabinets and other hardware components and special control software.

Main Specifications:

- Display accuracy: ≤±0.05mm

- When the lower roll is lifted and the side roll is inclined and lifted and the displacement is synchronously controlled, the synchronization accuracy is: ≤±0.1mm

- Sensor displacement resolution: ≤0.05mm

CNC Control System

SC Machinery control system for 16x2500mm 4 roller plate bending roll is equipped with an automatic rolling program, which can realize one-button operation. It can automatically roll and roll once at a time. It also has data number, storage and recall functions, and can store hundreds of data. Various specifications of automated rolling. The system is compatible with manual operation programs and can be manually operated when needed.

Top Support System: (Optional)

The inner rack is the top bracket and is mounted on the rear fuselage.

It consists of a movable stand. The bracket can be translated from the upper part to the lower part according to the size of the barrel, and supports the barrel during the rolling stage. The center stand can be hydraulically and electrically controlled.

Electric Feeding Platform: (Optional)

Electric feeding platform for CNC 4 roller plate rolling machine composed of roll, motor, reducer, hydraulic cylinder, etc. It is used for holding and feeding steel plate to be rolled. Ship and adjust the steel plate to the rolling machine for processing.

Left And Right Support System(Side Support System): (Optional)

Both sides of the hydraulic support or outside support frame: for large-diameter workpiece on both sides of the holding, to prevent the steel plate rolling process due to weight caused by poor rolling accuracy is not good. The hydraulic support has multiple rows of rolls to better hold the piece. Hydraulic support can be used for raceway when it is flat.

Cone Bending Attachment: (Optional)

The cone bending attachment is based on the principle of relative motion. The workpiece and the lower roll or side roll is regarded as stationary, the upper roll is pressed down, and the roll is pressed down and tilted when the cone is reeled. The greater the amount of reduction, the greater the contact area between the workpiece and the upper roll and the curvature around it becomes larger. The workpiece is rotated by the rotary motion of the work roll, and at the same time, the amount of reduction of the upper roll is constant, and each of the busbars of the workpiece has the same curvature. Or curvature distribution, become a cone.

Technical Parameter

Model: W12-16×2500 | ||

1. | Bending thickness | 16mm(12mm for stainless steel) |

2. | Max. Bending width | 2500mm |

3. | Roll working length | 2550mm |

4. | Symmetrical Rolling | T16*B2500*minφ700mm(σs≤245MPa) |

5 | Asymmetric Rolling | T12*B2500*minφ700mm(σs≤245MPa) |

6. | Upper roll DIA | Ф320mm |

7. | Lower roll DIA | Ф280mm |

8. | Side roll DIA | Ф240mm |

9. | Motor power | 15KW |

10. | Source of power | Hydraulic |

11 | Driving model of roll | Hydraulic motor and planetary gearbox |

12 | Operating speed | 4.5m/min |

13 | Voltage and frequency | 380V, 3 phase, 50Hz(can be customized) |

14 | Max. Working pressure of hydraulic system | 19Mpa |

15 | Control system (CNC controll) | Compatible with CNC automatic and manual control |

|

| Our company’s control system is equipped with an automatic rolling program, which can realize one-button operation. It can automatically roll and roll once at a time. It also has data number, storage and recall functions, and can store hundreds of data. Various specifications of automated rolling. The system is compatible with manual operation programs and can be manually operated when needed. |

16 | Min rolling diameter | 700mm |

Remarks: 1. Length of remain straight edge≤1.5 times of plate thickness.

2.Bending precision, roundness, linearity, ends surface error all less than 2mm/m.

Request Informations

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.