Automobile Manufacturing Background

In recent years, with the rapid development of the automobile manufacturing industry, the production lines of the automotive manufacturing industry have also been constantly updated and upgraded. Among them, the research on automated production line technology for automotive sheet metal has become a focus of public attention. This automated production line technology plays an important role in manufacturing automobiles, as it can make the manufacturing process more efficient, cost-effective, and of higher quality.

In the traditional sheet metal production process, more manpower and mechanical equipment are required to complete processing and assembly. After adopting automated production line technology, various links can be connected together to form a unified production process, greatly shortening the production cycle and improving production efficiency.

Under traditional production methods, it requires a significant amount of labor and equipment input, resulting in higher costs. The application of automated production line technology can greatly reduce production costs, as this technology can reduce labor input and material waste, improve production efficiency, and also achieve cost control.

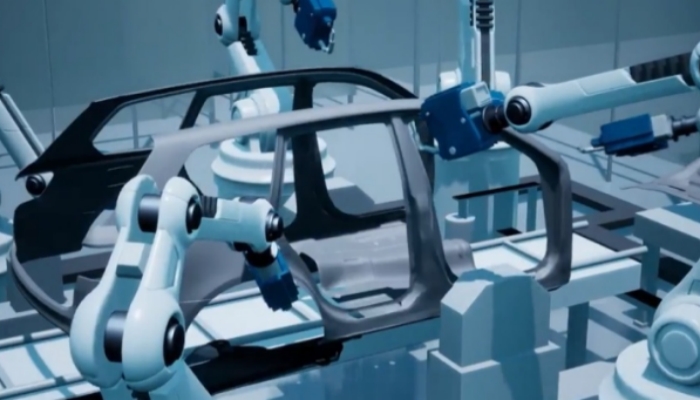

Automated production line technology can delegate most of the work to robots, thereby reducing the labor intensity of employees and improving their working environment. This can not only improve the work quality and efficiency of employees, but also enhance their work enthusiasm and satisfaction.

Automotive Automated Sheet Metal Production Line

The production line should include raw material storage area, cutting area, processing area, finished product storage area, etc.

The raw material storage area should include sheet metal raw materials used for cutting.

The cutting area should be equipped with laser cutting machines or other suitable cutting equipment.

The processing area can include bending, stamping and other equipment for further processing of cut sheet metal parts.

The finished product storage area is used to store processed sheet metal parts.

Automobile Manufacturing Machines

Fiber Laser Cutting Machine

Used for precise cutting based on preset drawings or data.

The rapid development of the automotive industry is inseparable from advanced manufacturing technology. Laser welding and laser cutting technology are widely used in the automotive industry due to their high energy, precision, and adaptability. 50% -70% of automotive components in developed industrial countries in Europe and America are processed using laser technology.

Laser cutting machine equipped with fully automatic loading and unloading is an essential cutting automation unit in automotive sheet metal processing automation production lines.

Robotic Press Brake Machine

Used to bend the cut sheet metal parts into the desired shape.

Given the size of automotive sheet metal, in general automated production lines, the CNC press brake equipped with a robot will use the 7th axis to increase the range of motion of the bending robot to meet the corresponding bending requirements.

CNC Turret Punch Press Machine

Used for punching sheet metal parts into more complex shapes or performing operations such as punching holes.

Generally, CNC turret punching is used. In fully automated automotive production lines, automated loading and unloading are used to connect CNC turret punching with other equipment.

Robots Or Automation Equipment

Used for handling raw materials and finished products, as well as logistics transmission between various production processes.