Wuxi Shenchong Forging Machine Co., Ltd. was established in 2002, specializing in the production of press brakes, shearing machines, rolling machines and other sheet metal processing machinery. Shenchong focuses on the R&D and production of sheet metal equipment and automation, and is committed to leading the sheet metal manufacturing industry into a new era of automation.

Wuxi SHENCHONG was proved through ISO9001 certification in 2004. Our company got export certification in 2003 and TUV CE certification from Germany in 2006.

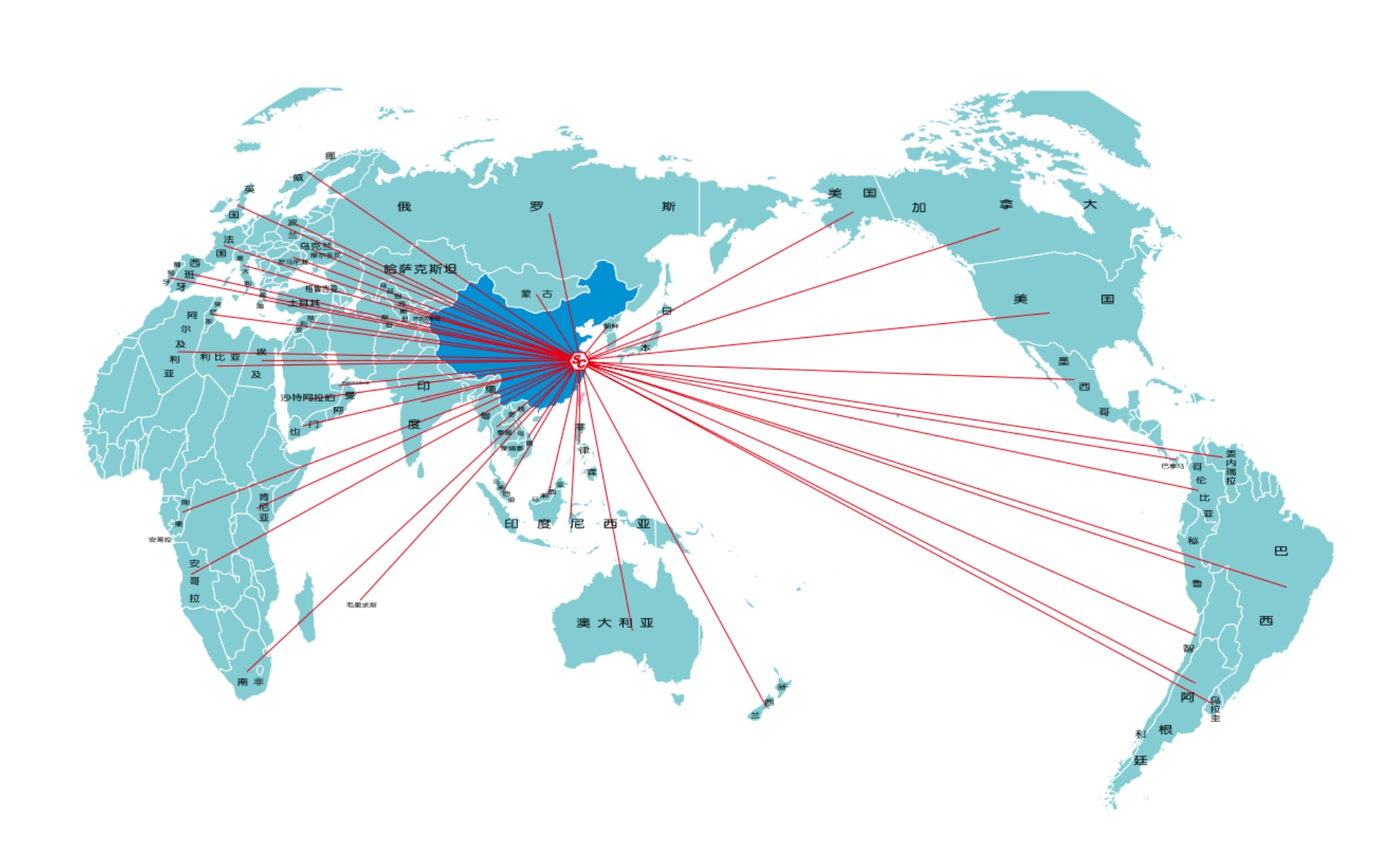

Due to high quality, reliability, high automation level and low energy consumption of our laser cutting machines and cnc bending machines, SHENCHONG win customers around the world. Till now SHENCHONG has exported their machines to over 120 countries worldwide. SHENCHONG fiber laser cutting machine, cnc press brake machine, plate rolling machine, shearing machine, sheet metal automation systems are widely applied in a multitude of industries, such as household appliances, elevators, the military, engineering machinery, boilers, shipping, containers manufacturing, etc..

At SHENCHONG, we take pride in our ability to innovate. We create new technologies, improve manufacturing processes and introduce never-before-seen products to the marketplace. Our team is able to improve overall performance, while remaining lean and efficient. These are the reasons why we’re leaders in our industry. Although it is important for us to continue pushing the industry as a whole forward, our customers remain our number one priority. To ensure our customers are completely satisfied, we offer only the highest-quality products and a dedicated support staff. Our team provides comprehensive pre-sales, sales, and after-sales services for every customers. We will help you understand installation and operation, and optimize the process to fully utilize your machines. If necessary, we send our engineers to your workshop for installation and training.

As a leading manufacturer of intelligent laser cutting machine, cnc press brake and cnc panel bender, SHENCHONG takes pride in ensuring that its machines are of the highest quality. Our commitment to quality control is reflected in every aspect of our manufacturing process, from the initial design phase to final assembly and machine testing. We have a team of well-trained quality control engineers team who carefully inspect and test each machine to ensure it meets our strict quality standards. We use only the reliable qualified materials and components, and the manufacturing process is optimized for precision and reliability.

The quality of SHENCHONG products is a result of our commitment to innovation, as well as our adherence to all certifications and regulations. SHENCHONG R&D team ensure the machine quality and satisfy your machinery requests. SHENCHONG has met the requirements set by the UNI EN ISO 9001:2008 since 2009. That means our customers can count on the fact that all our production and management processes are under constant supervision, including before and after products are sold. All SHENCHONG products also include the CE marking, which signifies they abide by health and safety standards that are required of certain products sold within the European Economic Area.

Globalization Strategy and Whole Industry Chain Layout

To provide high-end automation equipment and high-quality service system for global users, with products sold in more than 120 countries and regions, and service networks covering global terminals

Wuxi Shenchong Forging Machine Co., Ltd. was established in 2002, specializing in the production of press brakes, shearing machines, rolling machines and other sheet metal processing machinery.

SC SHENCHONG got the 9001 certification, obtained the TüV CE certificate and began to promote its products to the international market.

In 2005, the company designed the touch screen press brake and CNC shearing center, which won the Jiangsu High-tech Award and became the high-tech enterprise of Jiangsu Province in the same year.

SC SHENCHONG innovated 9-axis CNC pres brake and can export machines exempt from inspection.

SC exported our first laser cutting machine to Tunisia.

In 2014, SC SHENCHONG manufactured hybrid servo press brake. In 2015, manufactured robotic press brake. In 2016, full automatic unmaned tandem press brake 2000T/12000MM.

In 2017, SC manufactured full automatic intelligent sheet metal storage system. In 2018, we manufactured automatic cantilever type loading unloading system.

Since 2018, develop various types of metal sheet metal unmanned automatic production lines.

Choosing SC SHENCHONG means choosing good machine, good quality, good service and better future.

Creating the value of success through customer satisfaction.

Challenge • Change • Creativity • Content • Credibility

The future of manufacturing is undoubtedly digital. With the fourth industrial revolution taking over (a.k.a Industry 4.0), the Industrial production must adapt and cannot escape to the new reality of Industry 4.0, a production model in which all elements of the chain must be interconnected and communicate with one another.

Thanks to the advanced SHENCHONG® CNC and interconnecting ad-hoc software tools like the “Smart Factory” make it possible for companies to enter industry 4.0 that is revolutionizing the reality of companies. You can extract data and share information at company level: bending programs, sensors, production statistics.

In SHENCHONG, we have adopted the most advanced and efficient facilities and also use CAD & UG programs to process sheet metal machinery products.

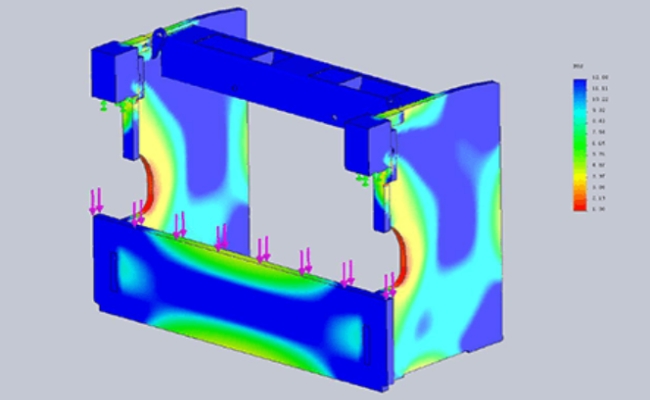

The CAE software SOLIDWORKS used as the method to analyze the linear static construction, stress and deformation for press brake and laser cutting machine frames. So for complicated structures, highly complex loading’s, transient modelling and combinations of the above, FEA makes sense. It also uses specific programs for the development and implementation of hydraulic and electrical systems to assure maximum effectiveness and durability of the solutions it offers.

SC press brake and laser cutting machine steel frames undergo annealing at over 600⁰ to relieve stress and they are built to last years of heavy use without distortion.

The structures of each machine are machined using modern milling machines and CNC machining centres. The skills in construction of any part assures optimised delivery and expedites availability of parts not in stock.

The machine frame goes through a heat treatment process for welding stress relief. SC SHENCHONG press brake and laser cutting machine frames are machined with 5 axis CNC machining centers with single reference fixing. This keeps all axis parallel and the surfaces of the machine precise which provides great accuracy and longevity to the machine.

SHENCHONG is a professional manufacturer engaged in sheet metal cutting and bending. We are committed to the R&D and production of laser cutting machines, automated sheet metal production lines, CNC press brake machines, plate shearing machine and plate rolling machine. Providing customized automated laser cutting and bending solutions for customers is our specialty. In addition, we also provide OEM services according to customer requirements.

SHENCHONG has exported their machines to over 120 countries worldwide.