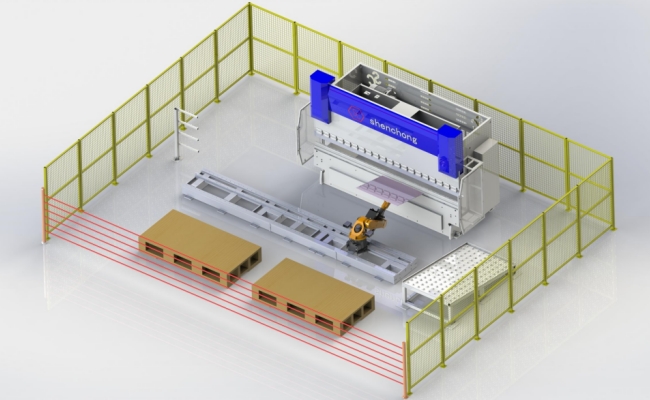

Robotic press brake machine is a CNC press brake that connect with bending robot to achieve full automatic bending function. SC SHENCHONG robotic press brake series can connect robot with hybrid servo press brake or CNC hydraulic press brake. We provide several different bending robot brands for customers to choose: ABB (Switzerland), KAWASAKI (Japan), STEP (China).

Robotic press brake is the most highest configuration choice in the current bending market. Our standard configuration for CNC press brake to connect with robot is 4+1 axis, CNC control the ram (Y1,Y2 axis), control the backgauge forward and back (X axis), control the backgauge up and down (R axis), control the table crowning (V axis). Of course, we will recommend suitable machine configuration for robotic press brake based on customers’ bending requirements.

|

Model |

Nominal Pressure |

Length of Table |

Distance between housings |

Throat Depth |

Stroke |

Open height |

Main motor Power |

Oil |

Overall dimension |

Weight |

|

kN |

mm |

mm |

mm |

mm |

mm |

KW |

L |

Lx W x H mm |

T |

|

|

40T/1300 |

400 |

1300 |

1000 |

250 |

160 |

400 |

5.5 |

130 |

1830*1430*2215 |

2 |

|

40T/1600 |

1600 |

1300 |

2130*1430*2215 |

2.8 |

||||||

|

40T/2000 |

2000 |

1500 |

2530*1430*2215 |

3.4 |

||||||

|

40T/2500 |

2500 |

2000 |

3030*1430*2215 |

4.2 |

||||||

|

63T/2000 |

630 |

2000 |

1500 |

320 |

160 |

400 |

7.5 |

200 |

2540*1640*2225 |

4.3 |

|

63T/2500 |

2500 |

2000 |

3040*1640*2225 |

4.8 |

||||||

|

80T/2500 |

800 |

2500 |

2000 |

400 |

160 |

410 |

290 |

3050*1650*2305 |

6 |

|

|

100T/2500 |

1000 |

2500 |

2000 |

400 |

200 |

450 |

11 |

3060*1690*2425 |

6.4 |

|

|

100T/3200 |

3200 |

2660 |

3720*1690*2475 |

7.3 |

||||||

|

100T/4000 |

4000 |

3200 |

4500*1690*2545 |

8.8 |

||||||

|

125T/2500 |

1250 |

2500 |

2000 |

400 |

200 |

450 |

3080*1760*2500 |

7.1 |

||

|

125T/3200 |

3200 |

2660 |

3740*1760*2535 |

8.2 |

||||||

|

125T/4000 |

4000 |

3200 |

4520*1760*2610 |

9.5 |

||||||

|

125T/6000 |

6000 |

4800 |

6650*1900*2950 |

13.5 |

||||||

|

160T/2500 |

1600 |

2500 |

2000 |

400 |

200 |

470 |

15 |

330 |

3100*1830*2520 |

8.7 |

|

160T/3200 |

3200 |

2660 |

3760*1830*2620 |

10.2 |

||||||

|

160T/4000 |

4000 |

3200 |

4540*1830*2720 |

11.4 |

||||||

|

160T/6000 |

6000 |

4800 |

6600*1950*2980 |

16 |

||||||

|

200T/3200 |

2000 |

3200 |

2660 |

400 |

200 |

470 |

3760*1880*2670 |

10.7 |

||

|

200T/4000 |

4000 |

3200 |

4540*1880*2770 |

12.2 |

||||||

|

200T/6000 |

6000 |

4800 |

6600*2200*3150 |

19 |

||||||

|

250T/3200 |

2500 |

3200 |

2660 |

400 |

250 |

490 |

18.5 |

3780*1980*2860 |

14.1 |

|

|

250T/4000 |

4000 |

3200 |

4560*1980*2960 |

16 |

||||||

|

250T/6000 |

6000 |

4800 |

6600*2250*3310 |

22 |

||||||

|

300T/3200 |

3000 |

3200 |

2660 |

400 |

250 |

500 |

22 |

540 |

3800*2080*3090 |

17.2 |

|

300T/4000 |

4000 |

3200 |

4580*2080*3090 |

19.5 |

||||||

|

300T/6000 |

6000 |

4800 |

6600*2250*3500 |

28 |

||||||

|

400T/4000 |

4000 |

4000 |

3200 |

400 |

300 |

605 |

30 |

900 |

4580*2460*3600 |

26 |

|

400T/5000 |

5000 |

4000 |

5600*2460*3750 |

30 |

||||||

|

400T/6000 |

6000 |

4800 |

6600*2460*3950 |

32 |

Model | Grab Weight (kg) | Max. Working Radius | Repeat Position Accuracy |

IRB6700-150 | 150 | 3200 | 0.05 |

IRB6700-200 | 200 | 2600 | 0.05 |

IRB6700-300 | 300 | 2700 | 0.05 |

IRB7600-340 | 340 | 2800 | 0.08 |

IRB7600-500 | 500 | 2550 | 0.08 |

Model | Grab Weight (kg) | Max. Working Radius | Repeat Position Accuracy |

RSO20N | 20 | 1725 | ±0.04 |

RS050N | 50 | 2100 | ±0.06 |

RSO8ON | 80 | 2100 | ±0.06 |

Model | Grab Weight (kg) | Max. Working Radius | Repeat Position Accuracy |

SR20/1700 | 20 | 1718 | ±0.05 |

SR60/2280B | 60 | 2281 | ±0.1 |

SR90/2280B | 90 | 2281 | ±0.1 |

SR165/2580 | 165 | 2586 | ±0.25 |

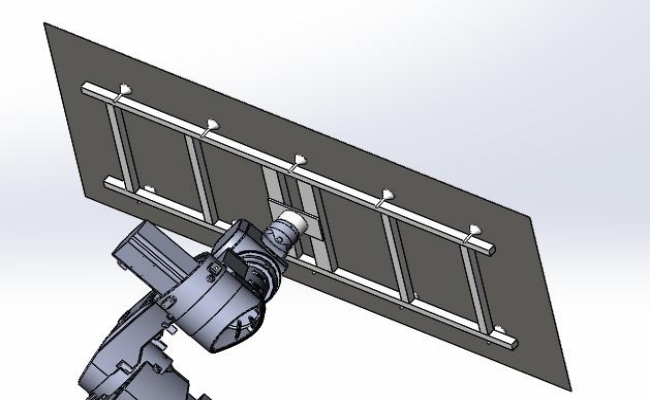

Customize the grippers based on the workpieces.

Standard provide 2 sets of gripper.

The magnetic separator is a piece of iron plate that uses the principle of magnetic pole line division to adhere to a thick oil or irregularly shaped iron piece (the material is iron, nickel, cobalt, that is, a metal that can attract the magnet), and is quickly separated.

To ensure that the surface of the sheet is smooth and seamless, and then use the suction cup or robot to transport the iron sheet material to the specified position for processing and automation. The operation is simple, convenient to use, and saves time, labor, and cost. Better work efficiency.

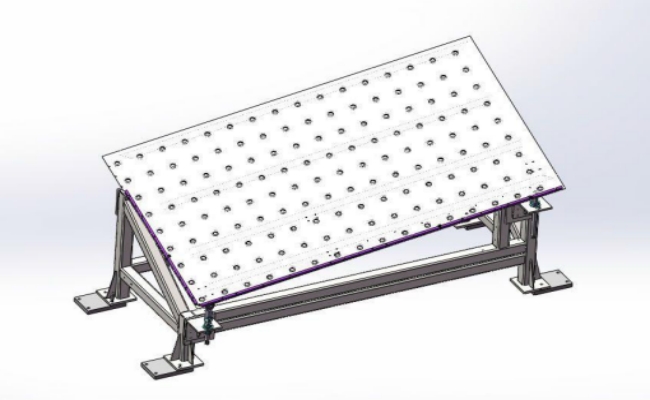

After the manipulator to the raw material area absorbs the sheet material and mechanically stratifies, the single sheet material is placed on the centering table to be positioned by the sheet material.

The table top is tilted to facilitate automatic alignment of the product.

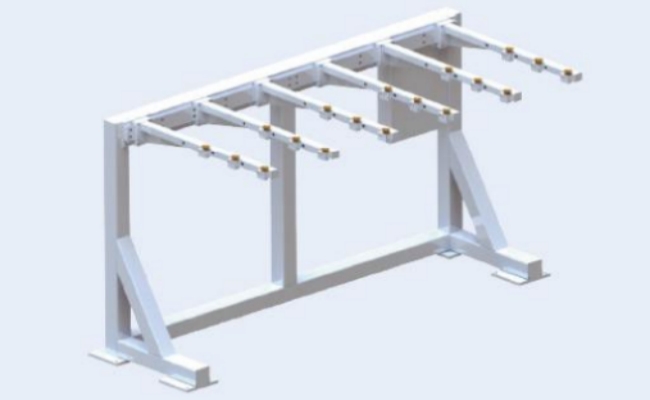

The robot places the workpiece that needs to be turned over on the front suction cup, and then grabs the workpiece from the reverse side.

As the latest bending solution, one popular tend is use robot bending in full automatic sheet metal processing production line. Also, customers always choose robotic press brake unit to bend batch production of workpieces.

As a robotic press brake manufacturer, SC SHENCHONG our own automatic bending engineers to provide you with customized robotic press brake machine proposal, including design special press brake tools, customized grippers, equipment layout… We have our own robot adjustment engineers to help you install the machine and provide systematic training. We do not use outsourced teams and so customers do not need to wait for service.

SC SHENCHONG has experienced robotic bending design engineers and robotic adjustment engineers who can provide quick response service for customers. We do not use outsource robotic design and adjustment team that means our engineers know very well about our own machines and robots, and so we can offer more professional design and service.

Shenchong is one of the top 5 CNC hydraulic press brake brands from China with full experience in exporting and excellent global market reputation. Shenchong press brake for sale has ISO9001, CE and all other certifications as quality trust endorsement.

We have produced robot press brake machine for more than 10 years and have rich experience in install and adjust the robot.

Direct factory price and experienced over-sea after sales team not only provides best robot press brake price but also eliminate customers’ concerns about any bending machine problems.

Every customer can get direct CNC robotic press brake price from us. Shenchong is one of the top press brake manufacturers, and we can offer you detailed technical proposal and price. Please provide us your plate material type, max thickness, max width, and workpiece drawings.

Yes, Shenchong is a reliable China hydraulic robotic press brake manufacturer with full exporting experiences. Installation Services are available with all our machines. We dispatch technician to customer’s factory for installation and pre-operation of machines. (Customers need to pay the airfare, hotel, food and engineer fees.)

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.