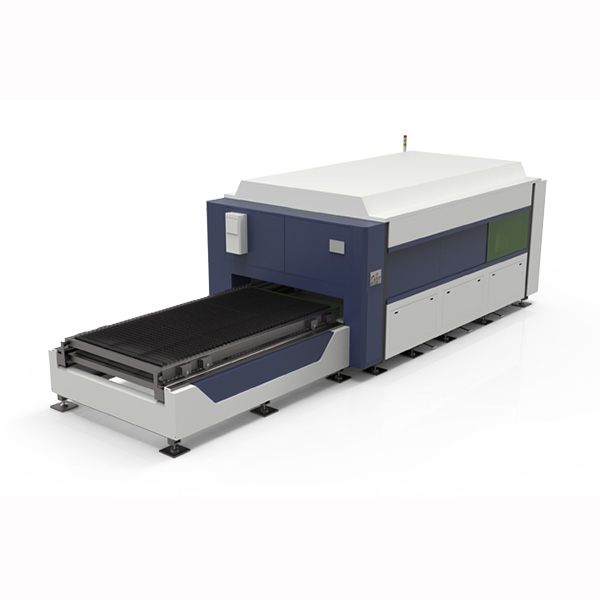

The tube fiber laser cutting machine is a kind of laser cutting machine specifically designed for cutting metal pipes and tubes, which can efficiently complete the cutting process of metal pipes. SC Shenchong provides solutions to meet various manufacturing needs in cutting and processing pipes, tubes, and structural steel. The pipe laser cutting machine not only provides superior laser cutting technology, but also integrates many additional processing functions, bringing value-added advantages to manufacturers.

The fiber laser tube cutting machine can cut all metal pipes quickly and accurately. The pipe laser cutting system integrates many intelligent machine functions, including intelligent monitoring, setting, and cutting functions. These automatic functions improve operational convenience and machine cutting efficiency. The wide range of functions of pipe fiber laser cutting machines let them become ideal choices for many industries.

SCCT laser cutting machine is a professional fiber laser cutting machine for pipes. It can cut any programmed shape on metal pipes, and laser can achieve perfect cutting in any direction. Through computer programming, the shape after processing can be flexibly and quickly changed. The high flexibility of laser pipe cutting machines provides strong technical support for increasingly personalized metal processing, thereby reducing the number of molds used.

|

Item |

Parameter |

|

Pipe Diameter (mm) |

120/160/220/280/320/350/450 |

|

Pipe Length (mm) |

3000/6000/9000/12000 |

|

Number of Chucks |

2 |

|

Positioning Accuracy (mm) |

±0.05 |

|

Repetitive Positioning Accuracy (mm) |

±0.03 |

|

Positioning Speed (mm/min) |

90 |

|

Maximum Acceleration (G) |

1 |

|

Max. Chuck Rotating Speed |

80-120 |

|

Maximum Remaining length (mm) |

120 |

|

Laser Power (W) |

1000-6000 |

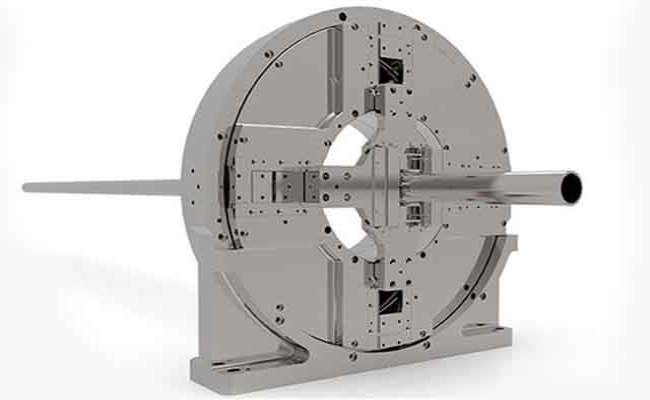

The two sides are designed with pneumatic fixtures, which can automatically adjust the center and have three times faster speed than that of the electric chuck. The clamping force of the self centering chuck is large and constant, which can effectively maintain the cutting accuracy of the pipe. In addition, it also has professional pipeline support function, avoiding tube sagging and deformation, precise and durable.

The Raycus laser generator not only has higher photoelectric conversion efficiency, but also provides more stable optical quality to ensure more stable and refined cutting effects.

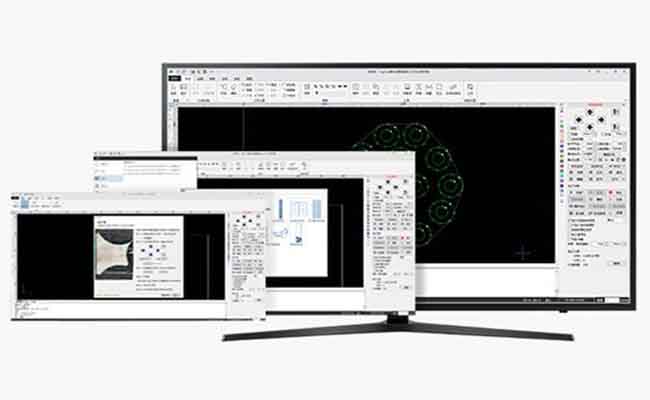

Adopting the Cypcut 3000S laser cutting system, it is simple, economical, practical, and convenient for human-computer interaction. The cutting system has rich built-in fiber laser cutting processes and parameters, and supports advanced functions such as workpiece edge finding, automatic focusing control, and breakpoint positioning. The cutting system has high integration and intelligence, integrating file reading, design, output, and machining control.

No need for manual focusing: This software automatically adjusts the focusing lens to achieve automatic perforation and cutting of plates with different thicknesses. The autofocus lens is ten times faster than manual focus.

Wider adjustment range: adjustment range -10mm~+10mm, accuracy of 0.01mm, suitable for different types of 0-20mm sheets.

Durable: Both the collimator and focusing lens are equipped with water-cooled sheets, which can reduce the temperature of the laser cutting head and improve its service life.

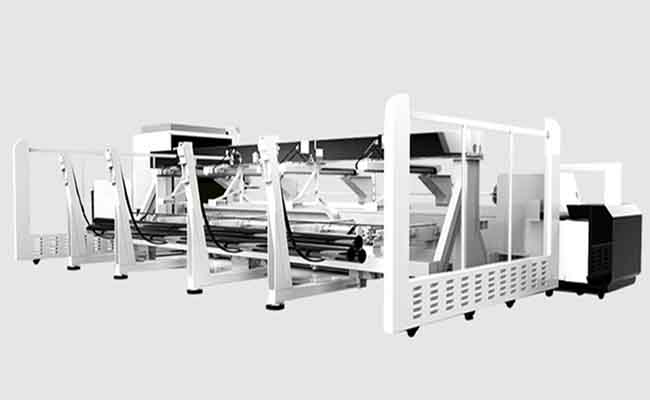

SCCT-Q laser cutting machine is an automatic tube fiber laser cutting machine with loading and unloading function. The automatic loading and unloading device automatic feed and unload the raw material and finished workpieces, which can improve production efficiency.

|

model |

SCCT-Q |

Work Area |

200*6000mm |

|

Minimum straight width |

0.1mm |

|

|

|

Control System |

Cypcut Control System |

Transmission |

Y-axis Gear and Small Gear; Z-axis Ball Screw |

|

Maximum Cutting Speed |

35m/min |

Maximum Speed of X-axis |

65m/min |

|

Y-axis Maximum Speed |

100m/min |

Z-axis Maximum Speed |

30m/min |

|

Cooling Method |

Water Cooling, Industrial Water Cooler |

Laser Generator |

Reci / Raycus / IPG |

|

Electronic Components |

Schneider, France |

Motor |

YASKAWA |

After placing the entire bundle of pipes into the feeding device, intelligent material separation, feeding, and seamless docking with the fiber laser cutting machine are achieved, ensuring that only one pipe is transported to the conveying arm at a time.

The finished product automatically falls into the silo, and dual support bearings assist in supporting the ultra long pipe.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.