Table of Contents

Chile CNC Press Brake 400T 4000MM is a heavy-duty, high-precision sheet metal processing equipment suitable for bending and forming a variety of metal materials. This model adopts the advanced ESA S630 CNC system, which can provide precise bending control and efficient production capacity. It is suitable for aerospace, automobile manufacturing, construction engineering, heavy machinery manufacturing and other industries.

1. Technical parameters and components

1) Basic parameters of Chile CNC press brake machine

Parameters | Specifications |

Bending tonnage | 400 tons |

Bending length | 4000 mm |

Throat depth | 500-600 mm (optional) |

Slider stroke | 250-320 mm (optional) |

Opening height | 500-600 mm (customizable) |

Back gauge stroke | 600 mm (optional extension) |

Axis configuration | 4+1 axis or 6+1 axis (expandable) |

Control system | ESA S630 |

Number of cylinders | 2 high-precision hydraulic cylinders |

Body structure | Overall welded steel structure |

Main motor power | 30-45 kW (depending on the configuration) |

2) Key components

- Hydraulic system:Adopt internationally renowned brand hydraulic system to ensure stability and durability.

- Servo motor and drive:Adopt high-precision servo motor to improve bending accuracy.

- Back gauge system:High-speed and high-precision ball screw and linear guide to ensure the stability and repeatability of back gauge.

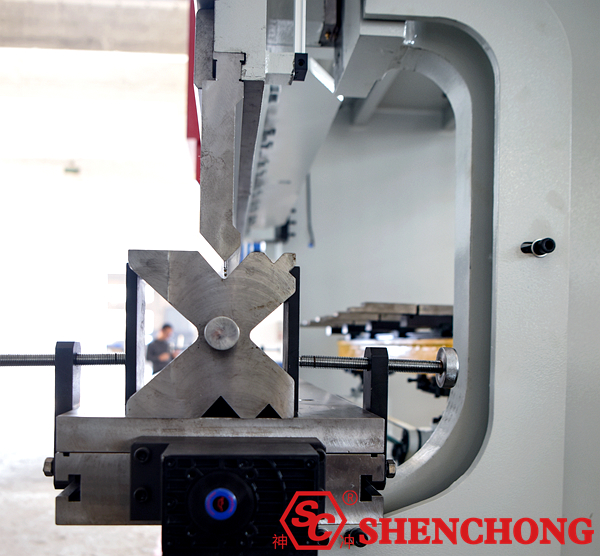

- Upper and lower diesystem: Standard segmented upper mold and integral V-shaped lower mold, special molds can be customized.

3) ESA S630 CNC system

ESA S630 is a high-performance bending machine control system developed by ESA, Italy, with an intuitive operating interface, powerful computing power and high-precision control technology.

Main features:

- 4-inch color touch screen, intuitive operating interface, support for multiple languages.

- 2D programming function, support for rapid input of bending parameters, and provide workpiece bending simulation.

- Automatic calculation of bending compensation, automatic calculation of bending force and compensation amount according to material thickness and bending angle.

- Support USB and network connection for convenient program storage and remote maintenance.

- Intelligent tool management, support for different tool configurations, and automatic identification and replacement.

- Multi-axis control, can control Y1, Y2, X, R, V axes to ensure high-precision bending.

Main functions:

ESA S630 is a high-end bending machine control system of ESA, Italy, with graphic programming, automatic bending calculation, simulation and other functions, which can significantly improve production efficiency and bending accuracy.

15.6-inch HD touch screen

- Intuitive interface, supports 2D/3D graphic programming, and can directly simulate the bending process.

- Uses Windows operating system and supports multiple languages (including Chinese).

Intelligent bending calculation

- Automatically calculates parameters such as bending angle, bending force, back gauge position, etc., reducing manual intervention and improving bending accuracy.

- Automatically compensates for sheet rebound error to ensure accurate processing dimensions.

Multi-axis control: 4+1 axis or 6+1 axis

- Y1, Y2: Independent control of left and right cylinders)

- X: Back gauge moves forward and backward)

- R: Back gauge moves up and down)

- V: Workbench compensation)

- Optional Z axis: Left and right gauge moves to increase bending flexibility.

USB & remote networking function

- Supports USB import/export program, and can directly load DXF drawings.

- Wi-Fi/Ethernet remote connection, supports remote diagnosis and software updates.

2. Chile press brake machine structure and design

1) Frame structure

- Adopt high-strength steel plate welding, tempered to ensure high rigidity and deformation resistance of the frame.

- Gantry structure design ensures long-term work without deformation and improves bending stability.

2) Hydraulic system

- Adopt internationally renowned brand hydraulic system to provide efficient and stable pressure control.

- Servo proportional valve + pressure compensation system to ensure bending consistency.

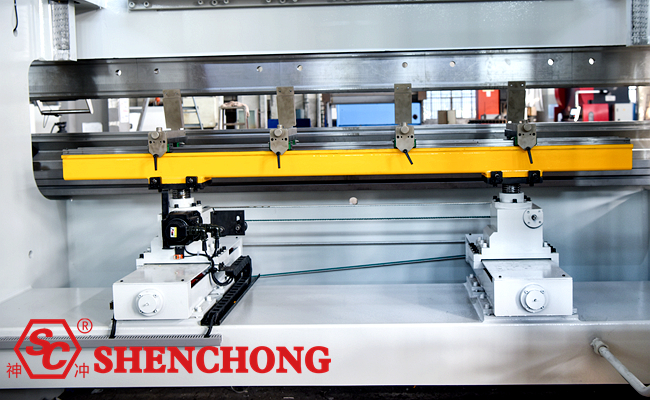

3) Servo motor & back gauge

- Servo motor drives the back gauge (X, R axis), and the positioning accuracy can reach ±01mm.

- Ball screw + linear guide is used to make the back gauge move more accurately and smoothly.

3. Equipment functions and advantages

1) Bending accuracy

- Y1 and Y2 double cylinders are independently controlled, real-time monitoring and automatic compensation of deviations are carried out to ensure that the slider synchronization accuracy is ≤ ±01mm.

- Servo-driven back gauge, repeated positioning accuracy is ≤ ±05mm.

2) Energy saving and high efficiency

- The electro-hydraulic servo synchronization system is adopted to improve hydraulic efficiency and reduce energy consumption.

- The ESA S630 control system optimizes the bending path, reduces empty strokes, and improves production efficiency.

3) Safety protection

- Equipped with grating protection (such as SICK, Fiessler) to ensure safe operation.

- An emergency stop button is provided to prevent safety accidents caused by misoperation.

4) Ease of operation

- Graphical programming, visual simulation of the bending process, and lowering the operating threshold.

- Compatible with multiple data input methods (USB, WiFi, network) for convenient file management.

4. Application industries

- Aerospace: manufacturing aircraft skins, fuselage structural parts, etc.

- Automobile manufacturing: production of automobile bodies, chassis parts, etc.

- Heavy machinery: used for processing large steel components and mechanical equipment shells.

- Construction industry: used for sheet metal bending of metal curtain walls, steel structure buildings, etc.

5. Optional functions

- 6+1 axis: add Z axis to improve the flexibility of material blocking

- Laser safety protection system: ensure safe operation

- Cooling system: prevent overheating during long-term high-load work

- Bending follower: reduce work intensity and facilitate bending of large-size plates.

- Robot manipulators: form an automatic bending production unit to reduce manual operation.

6. Summary

Chile CNC Press Brake 400T 4000MM ESA S630 is a heavy-duty CNC plate bending equipment suitable for processing large-size, high-strength metal sheets.

- High-precision bending: ESA S630 controller + servo hydraulic system to ensure ±01mm accuracy.

- Intelligent operation: 2D/3D bending programming, automatic calculation of bending parameters, and reduced reliance on manual experience.

- Efficient production: USB reading program + remote networking, fast switching of processing tasks.

- Stable and durable: high-strength steel frame structure + imported hydraulic system to ensure long-term stable operation.

- Multiple expansion functions: upgradeable 6+1 axes, grating ruler measurement, automatic feeding and other functions.

The equipment uses the ESA S630 controller to provide high-precision bending control. It has the characteristics of high precision, high efficiency and easy operation, and is suitable for various precision sheet metal processing needs. It is widely used in machinery manufacturing, steel structure, automobile, aerospace, shipbuilding and other industries.

If you need detailed technical information, prices or customized solutions, you can contact SC Machinery professional press brake manufacturer to obtain specific information!