Table of Contents

The Czech mini CNC press brake 20ton 1000mm is a kind of equipment specially used for small sheet metal processing enterprises. It is characterized by high efficiency, precision and easy operation, suitable for processing small workpieces and providing high-quality bending effects.

This Czech user-customized small plate bending machine is a high-speed and high-precision CNC press brake widely used in the manufacturing industry for sheet metal bending processing. The following is a detailed introduction of this model.

Czech mini CNC press brake machine model

- WG67K series high-speed mini CNC press brake

- 20Ton 1000mm

- 4 axis, (Y,X,R,Z)

- Mitsubishi controller

Basic parameters:

- Rated pressure (tons): 20 tons

- Maximum bending length (mm): 1000 mm

- Workbench length (mm): generally 1000 mm, suitable for processing small workpieces.

- Bending angle: precisely adjusted by the CNC system, the bending angle is usually adjustable between 0° and 180°, depending on the processing requirements.

- Control method: CNC system (CNC), usually equipped with a touch screen operation interface to facilitate the operator to set parameters.

Performance advantages of mini CNC bending machine

High-precision CNC system:

Using advanced CNC technology, the CNC system can accurately control the bending angle, position and pressure to ensure high precision and repeatability of each bending.

- Efficient and high-speed work:

The mini high-speed CNC press brakeadopts high-frequency drive technology. The bending speed is usually between 200mm/min and 300mm/min, which is faster than the traditional CNC bending machine and can greatly improve work efficiency.

- Compact body design:

The mini design saves space and is suitable for small workshops or workstations with limited space. It also has high rigidity and stability.

- Servo motor drive:

The servo motor drive system is more energy-efficient than the traditional hydraulic drive, and has faster response speed, higher stability and precision.

- Easy operation:

Equipped with a touch screen and an intuitive operation interface, the technician only needs to enter the relevant parameters, and the equipment can automatically perform the bending process.

Application areas of mini high-speed press brakes

The rated pressure of SC WGK high-speed mini bending machines is usually between 10 tons and 30 tons, which is suitable for processing thinner metal sheets (such as stainless steel, aluminum, copper, etc.). The bending length is generally between 1000mm and 2000mm, which is suitable for the bending needs of small-sized sheets.

- Sheet metal processing: suitable for processing various thin sheet metal materials, such as stainless steel, aluminum alloy, copper, carbon steel, etc.

- Electronic product shell processing: such as sheet metal processing of small electronic products such as mobile phone shells and computer shells.

- Home appliance manufacturing: suitable for sheet metal bending processing of small home appliances, kitchen appliances and other home appliances.

- Automotive parts: especially suitable for small batch and customized production of automotive parts.

- Mechanical parts: suitable for the processing of precision mechanical parts, especially customized parts that need to be produced in small batches.

Safety and maintenance

- Safety system:

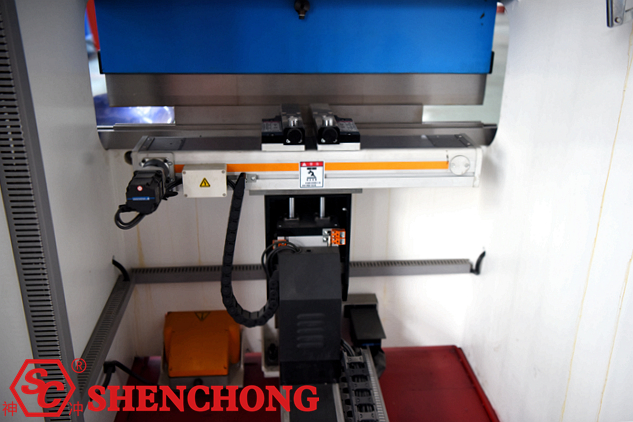

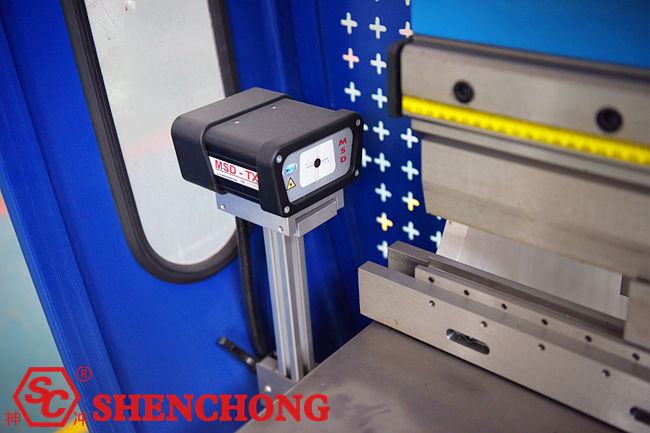

The equipment is usually equipped with safety protection devices, such as emergency stop buttons, photoelectric protection devices, etc., to ensure the safety of operators.

- Maintenance:

Regularly check the oil pressure system, electrical control system and mechanical components to keep the equipment in good operating condition.

This Czech mini high-speed CNC press brake for sale is an ideal choice for small factories and workshops with its high efficiency, high precision, energy saving and environmental protection and compact design. It provides users with high-efficiency, stable and flexible bending solutions through precise CNC system, servo motor drive and high-speed operation.