Table of Contents

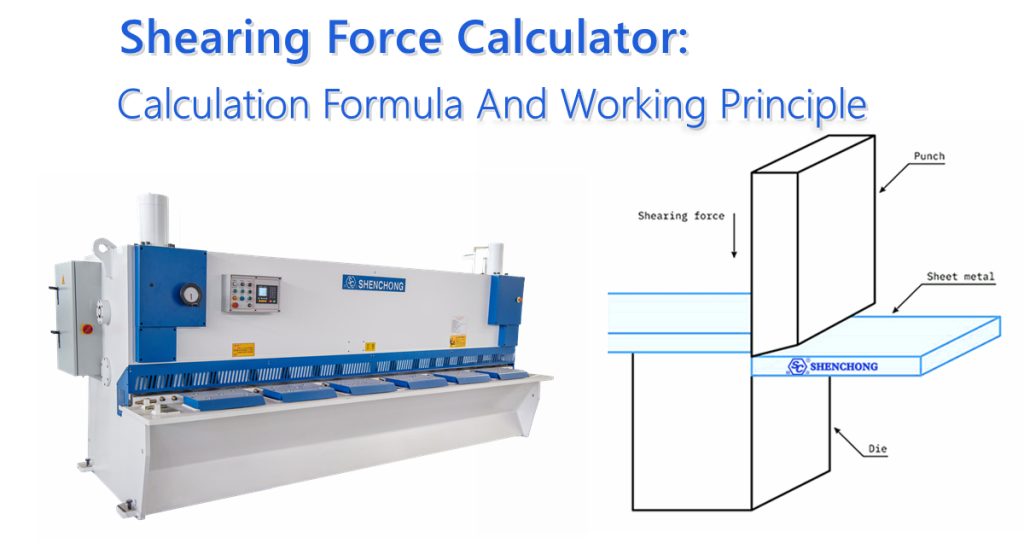

SHENCHONG shearing force calculator helps in determining the force required to cut or shear a material, typically used in processes like sheet metal cutting, punching, or other shearing operations. Shear force of metal plate is the force applied to the metal plate by the shearing machine blade, which causes the plate to deform along the shearing direction and eventually break.

The calculation formula of shear force of metal plate is mainly based on the shear strength of the material, the thickness of the plate and the cutting length. Understanding these principles is crucial for effectively designing the shearing process, improving production efficiency and ensuring processing quality.

1. What is sheet metal shearing force?

Shear force is a force acting on the surface of an object and parallel to the surface, which attempts to cause relative sliding or deformation of the internal structure of the object. In short, shearing force is a force that causes shear deformation of an object.

When shearing force acts on an object, a stress that resists shear deformation is generated inside the object, which is called shear stress. If the shear force exceeds the shear strength of the material, the object will be sheared or broken.

Metal plate shearing force refers to the force applied to the metal plate by the shearing machine blade or other tools when cutting metal plates. This force acts on the surface of the metal plate and along the cutting direction, causing the metal material to undergo plastic deformation and fracture under the action of the blade, thereby achieving cutting.

2. Working principle of shearing force

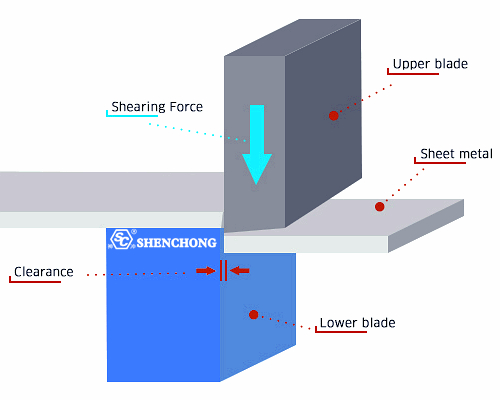

The principle of shear force on metal plates involves the force applied by the shearing tool (such as the blade of a shearing machine) on the metal plate during the shearing process, which causes the plate to undergo plastic deformation and eventually break and separate.

This process causes the metal plate to break along the shear line through the shear stress of the material. The following is a detailed introduction to the principle of shear force on metal plates.

1) Basic principles of shearing force

When shearing force acts on a metal plate, it causes shear deformation of the material. Shear deformation refers to the relative sliding of the layers of an object, not stretching or compression. When the shear force exceeds the shear strength of the metal material, the material will break along the shear direction.

2) The process of shear force

The process of metal sheet shearing can be divided into the following stages:

- Applying shear force

The plate shearing machine cutting blade (such as feeding blade, die, etc.) applies a force parallel to the plate surface to the metal plate. The shear force acts on the surface of the plate and is evenly distributed within a certain shearing area.

- Generation of shear stress

When the blade contacts the metal plate, the shear force acts on the metal surface through the contact surface, generating shear stress.

Shear Stress Calculation Formula

Shear stress refers to the shear force per unit area, and the formula is:

τ= A/F

Where:

τ: shear stress (unit: Pa)

F: shear force (unit: N)

A: shear area (unit: m²)

- Plastic deformation of materials

Metals undergo initial elastic deformation (small deformation) under shear force, and if the force continues to increase, the material will enter the plastic deformation stage.

During the plastic deformation stage, the molecular chains of the material begin to slip, resulting in permanent deformation, and plastic flow will occur in local areas of the metal.

- Fracture of materials

When the applied shear force exceeds the shear strength of the material, the metal will fracture. This fracture occurs along the shear direction (i.e. the cutting line of the blade), and the metal sheet is cut into two parts.

- Post-cutting processing

After the shearing is completed, the edge of the metal sheet may have irregular burrs or deformations, which usually require secondary processing.

3) Physical mechanisms in the shearing process

The shearing process of metal plates can be divided into three physical mechanisms:

- Elastic stage

When the shear force is very small, the metal plate undergoes only a small elastic deformation, the force is proportional to the deformation, and the material does not undergo permanent deformation.

- Plastic stage

As the shear force increases, the metal plate enters the plastic stage, and the internal structure of the material begins to slip. At this time, the lattice structure of the metal is deformed, and the material exhibits significant plastic flow characteristics.

- Fracture stage

When the shear force reaches or exceeds the shear strength of the material, the material begins to fracture. Fracture usually occurs along the shear surface (i.e., the area where the blade contacts) and may be accompanied by burrs or irregular edges.

The principle of shear force on metal plates is that the shear blade applies force to the metal plate, causing the plate to deform along the shear direction and eventually break. The magnitude of the shear force depends on the shear strength of the material, the thickness of the plate, the shear length, and other processing conditions. Understanding these principles is crucial for effectively designing shear processes, improving production efficiency, and ensuring processing quality.

2. How to calculate shear force?

Advanced Considerations:

In some cases, shearing force can be influenced by additional factors such as:

– Edge preparation: A properly prepared edge can reduce cutting force.

– Work hardening: In some metals, the material near the cutting edge can undergo work hardening, which could increase the shear force.

– Ductility: More ductile materials (such as aluminum) may require less force compared to brittle materials (such as cast iron), as they deform more easily under shear.

Step 1: Identify Shear Strength (τs)

The shear strength of the material must be known or looked up. Typical values for materials are:

– Mild steel: τs=250 MPa=(250 × 106 Pa)

– Aluminum: τs=140MPa

– Stainless steel: τs=350MPa

Step 2: Measure the Thickness (t) of the Material

Measure the thickness of the sheet or workpiece that will be cut.

Step 3: Measure or Define the Cutting Length (L)

This is the total length of the material that will be cut during the shearing operation. If you’re cutting a straight line across the sheet, the cutting length is the total length of the cut.

Step 4: Calculate the Shearing Force

Now, substitute the values into the formula.

3. Sheet Metal Shearing Force Calculator And Formula

The sheet metal shearing force calculator is mainly based on the shear strength of the material, the thickness of the plate and the cutting length. The following is a commonly used calculation formula for metal plate shear force:

1) Shearing force calculator

The shear force F of the metal plate can be calculated by the following formula:

F=τs⋅t⋅L

Where:

F: shear force (unit: Newton, N)

τs: shear strength of the material (unit: Pascal, Pa or N/m²). This is the yield strength or ultimate strength of the metal material in the shear state, usually given by the material manual or experimental data.

t: thickness of the metal plate (unit: meter, m)

L: shear length (unit: meter, m), that is, the length of the cutting line where the blade contacts the metal plate.

2) Example calculation of shear force

Suppose we need to shear a steel plate:

– Shear strength: τs=250MPa (i.e. 250×106Pa)

– Plate thickness: t=10mm=0.01m

– Shear length: L=1 m

Shear force is calculated as follows:

F=250×106⋅0.01⋅1=2.5×106N=2500kN

Therefore, the required shear force is 2500 kN.

3) Applicable scenarios

This calculation formula is applicable to single-blade shearing, that is, the blade cuts along one direction of the plate, and the shearing area is usually linear.

4. Practical application of metal shear force calculation

In actual production, in addition to the above basic formula, the following factors need to be considered:

Blade quality and design:

A sharp blade requires less shear force, and the angle, sharpness and friction characteristics of the blade will affect the magnitude of the shear force.

Pretreatment of sheet materials:

The heat treatment and annealing of the material may change its shear strength.

Multi-layer shearing:

If it is shearing of multiple layers of metal plates, the shear force of each layer needs to be calculated separately and summed.

Shearing speed and temperature:

The shear strength of metal decreases at high temperatures, and usually less shear force is required.

5. Conclusion

The shearing force calculator is a tool used to calculate the force required to shear or cut through a material. This is commonly used in engineering applications such as machining, metal cutting, or structural analysis. The calculation typically depends on the material properties, thickness, and the geometry of the cutting tool.

Understanding these principles is essential for effectively designing shearing processes, improving production efficiency, and ensuring processing quality. If you have further specific questions or application scenarios, please continue to ask questions!

Click here to know more about metal shearing: