With the continuous innovation and development of intelligent technology, the production mode of enterprises has also undergone tremendous changes, from the traditional production manufacturing mode that relies on manual labor in the production process to gradually using automated production equipment to replace manual intelligent automation production. This articles introduces the automatic sheet metal production line advantages and explain why more and more factories choose the automatic production line.

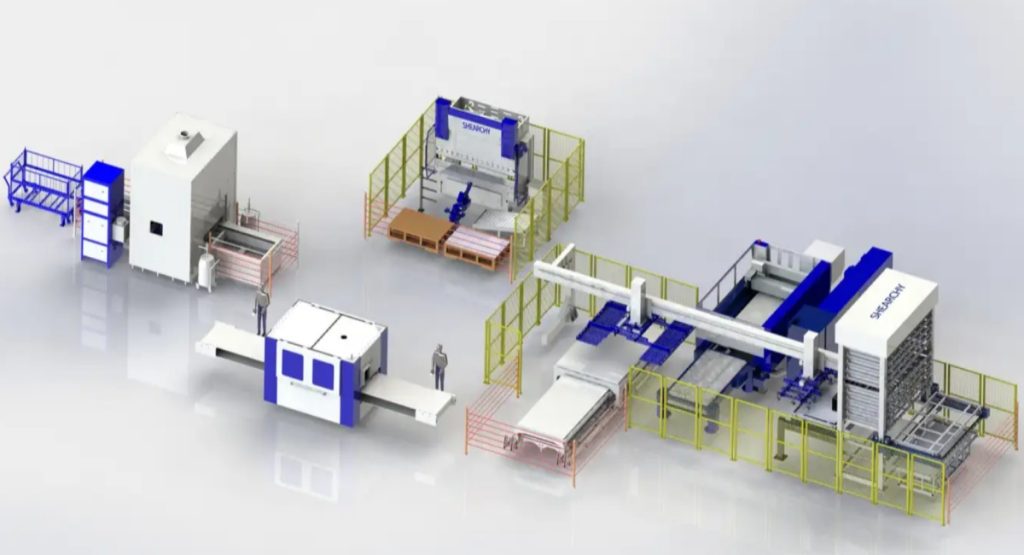

What Is An Automatic Sheet Metal Production Line?

The sheet metal automatic production line consists of a series of sheet metal forming workstations connected by a transmission system and an electrical control system. Each workstation performs a specific operation, and the products are processed step by step along the production line according to a pre-defined production sequence.

The use of automatic production lines liberates people from the heavy workload of repetitive tasks – replacing manual labor in tasks completed in hazardous environments and performing tasks beyond human size, weight, speed, and endurance. Products produced using automated lines should have sufficient production capacity. The product design and process should be advanced, stable, reliable, and maintain basic consistency over a long period of time. The use of automatic lines in large-scale production can improve labor productivity, stabilize and enhance product quality, improve working conditions, reduce production footprint, lower production costs, shorten production cycles, ensure production balance, and have significant economic benefits.

Automatic Sheet Metal Production Line Advantages

- Reduce operating costs

Automatic sheet metal production line usually use robots to connect and move the sheet metal plates during the processing. According to different tasks, robots can complete the work of three to five people. In addition to saving labor, lower heating requirements can be automated to greatly save energy. Robots have achieved program automation, improved part accuracy, and thus reduced material waste during operations.

- Increase worker safety

Workers were relieved of harmful tasks through automated units. Your employees will thank you for protecting them from the dangers of working in the factory.

- Shortened the manufacturer’s delivery time

Automation can keep your processes internal, improve process control, and greatly shorten delivery times.

- Greater investment return

Automated solutions are customized according to your specific needs and objectives. They can quickly recoup costs by reducing operating costs, shortening delivery times, increasing production, and other benefits.

- More effective competitiveness

Automated units can reduce cycle time and cost per item while improving quality. This can compete more effectively on the world stage. In addition, the adaptability of robots can readjust units to surpass competitors.

- Increased output

A robot can work at a constant speed without human supervision, 24 hours a day, 7 days a week. This indicates that you can produce more. New goods can be integrated into the manufacturing process faster, and programming for new products can be completed offline without interfering with existing operations.

- Stable and continuously improving production and quality of parts

The unpredictability of the production process completed by sheet metal automation units is less than that of manual labor. The product quality is more controllable and stable.

- Reduced environmental impact

Sheet metal automation saves energy by simplifying equipment and processes, reducing waste, and occupying less space. Reducing your impact on the environment may bring significant economic benefits.

- Improvement Plan

The stable output of the robot enables the workshop to estimate time and cost steadily. Due to this reliability, most projects can operate on a smaller scale.

- Optimal utilization of ground space

Robots are built on small bases to adapt to small areas. In addition to the ground, robots can also be installed on walls, ceilings, tracks, and shelves. They can complete work in small places, saving you important ground space.

- Simple integration

Wuxi Shenchong is collaborating with you to develop a complete solution, including hardware, software, and control.

- Maximizing Labor Force

Statistics show that over the next thirty years, more than 76 million baby boomer generation will retire, with only 46 million new workers available to replace them. During this period, your labor demand will remain high, making automation a true and practical solution.

- Improve productivity

These systems achieve automation of factories and industrial processes, enabling continuous large-scale production 24 hours a day, seven days a week, thereby improving productivity and reducing assembly time.

- High quality

By utilizing adaptive control and monitoring at various stages of the industrial process, these systems have successfully eliminated human errors, thereby improving the quality and homogeneity of the products provided. After several hours of continuous work, performance was not affected.

- Improve consistency

Machines and computers work at a consistent and constant speed. Therefore, when controlled by an automation system, the automated manufacturing process has longer length, stability, and stability.

- Measures to reduce costs

Although the initial investment in industrial automation systems may be enormous, the application of this technology will reduce the cost of data analysis. In addition, due to this automated data analysis, the risk of machine failures and service interruptions is minimized.

- Increase working conditions

In factories with industrial automation systems, workers have shorter working hours and more time for high value-added work.

- Increased added value

Due to the application of automation technology, employees no longer need to perform tedious and routine work. When the activities of machines and computers free employees from completing these tasks, they can perform more value-added tasks in other parts of the company, thereby gaining greater benefits.

- Enhance human abilities

The system used by enterprises for automated services can not only fulfill the responsibilities that humans would do, but also perform tasks beyond human capabilities. They have advantages in size, weight, speed, and resistance.

- Improve the adaptability of the system

The adaptability of the system enables it to readjust and reposition for new production plans at any time. Robots have strong adaptability and are easy to redeploy in new applications. Robots can switch between various projects at any time without the need to completely rebuild the production line.

With automatic grippers and vision, fast conversion can make different part sizes and shapes part of the same run. The mixed flow production method provides greater flexibility in responding to demand fluctuations. Robots can “learn” new processes in real-time. Reduced conversion time.

Conclusion

Generally speaking, the unpredictability of the production process completed by automated units is less than that of human workers. This has led to improvements in product control and uniformity, as sheet metal automation production lines are a process of raw material entry and finished product exit with little or no human intervention. In many ways, industrial automation technology provides special benefits. It is relatively safe to use robots on dangerous production lines.

SC Machinery is one of the most famous sheet metal automation production line supplier, we have professional engineer team, our own manufacturing factories and rich experienced after sales service team, which can provide the best design, products and service to clients.