SHENCHONG WEK 63 Ton 2000mm CNC Press Brake Machine 4+1 Axis With ESA S630 Controller

SC® 63 ton 2000mm cnc press brake is in WEK Series, which is perfect for forming small parts with low operating costs and with syncro CNC 4+1 axis control capability.

Y1, Y2 axis—controls the CNC axes of the cylinders on both sides. The X-axis controls the back gauge and forth of the back gauge, the R-axis controls the back gauge up and down, the Z1, Z2 axis control the back gauge finger left and right, and the V-axis table is CNC crowning.

Machine Feature

- The fuselage adopts integral welding and integral processing structure.

- Adopting the closed-loop control method composed of German electro-hydraulic servo valve and grating ruler, the slider position feedback accuracy is high, the operation is accurate and stable, the synchronization performance is good, and the bending accuracy is high.

- The numerical control system can realize the functions of bending angle graphic programming, angle correction compensation,automatic calculation and automatic adjustment of bending pressure, automatic calculation of the deformation compensation amount of the working table, the unfolded length of the work piece, and the automatic back gauge of the back gauge.

- ESA S630 controller controls the backgauge, which can continuous bend the complex workpiece .

Standard Configuration

63 Tons 2000mm CNC Press Brake Hydraulic Parts:

- Magnetic scale (ELGO Germany)

- Valve unit (ARGO-HYTOS Germany)

- Gear pump (SUNNY USA)

- Ferrule connector (EMB Germany)

- Sealing ring (SKF Sweden)

63 Tons 2000mm CNC Press Brake Electrical Parts:

- ESA S630 CNC controller (Touch Screen from ESA Italy)

- Main motor (SIEMENS)

- V axis table crowning (CNC controlled)

- Backgauge servo motor (DELTA Taiwan)

- Electrical components (Schneider France)

- Movable foot pedal for easy operation and emergency power off function

Machine Details

Safety Protection

Shenchong CNC press brake standard safety protection includes:

Side protection and back door protection

Electrical cabinet with ABB switch power off device

Fan in the electrical box prevent overheating

Cooling device to prevent overheating of oil tank

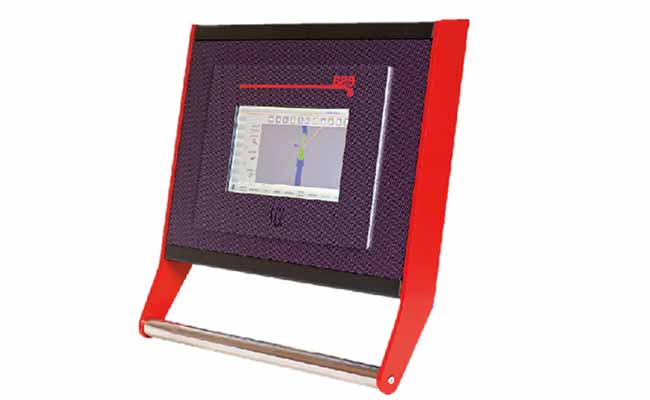

ESA S630 Controller

– Graphic color 10” touch screen display (1024 x 600 pixels resolution).

– 128 silicon disk.

– Interactive 2d graphic editor for work-pieces and tools data entry.

– 2D graphic display of machine frame, work-piece and tools.

– Manual 2D graphic identification of the best bending sequence(option)

– 32 digital outputs (24Vdc, 0,7A max.) protected against overload and short-circuits.

Technical Parameter

TYPE | WEK-63/2000(ESA S630) | ||

SR.NO. | ITEM | UNIT | SPECIFICATION |

1 | Nominal Pressure | kN | 630 |

2 | Length of Table | mm | 2000 |

3 | Distance Between housings | mm | 1500 |

4 | Throat Depth | mm | 320 |

5 | Stroke | mm | 160 |

6 | Approach speed | mm/s | 200 |

7 | Return speed | mm/s | 100 |

8 | Working speed | mm/s | 10 |

9 | Axis (4+1) |

| Y1, Y2, X, R+V |

10 | Y1, Y2 parallel tolerance | mm | ±0.01 |

11 | X-axis arbitrary positioning precision |

mm |

±0.025 |

12 | X-axis repeat positioning precision | mm | ±0.02 |

13 | X-axis speed | mm/s | 0-500 |

14 | X-axis positioning spacing | mm | 5-1000 |

15 | R-axis repeat positioning precision | mm | ±0.03 |

16 | R-axis speed | mm/s | 0-500 |

17 | R-axis positioning spacing | mm | 200 |

18 | Open Height | mm | 400 |

19 | Main motor | kw | 7.5 |

20 | Overall Dimensions (L*W*H) |

mm |

2540*1640*2225 |

21 |

Weight |

T |

4.5 |

Frequently Asked Questions

The price of a 63tons 2000mm cnc press brake can vary greatly depending on the machine series types, number of axes, configuration, and specification of the machine. Additionally, prices may also be affected by the country of manufacture, shipping and installation costs, and any additional taxes and charges. Under normal circumstances, the price of a WEK 63 ton 2000mm hydraulic CNC press brake for sale with basic functions ranges from $20,000 to $30,000. Plus, higher-end machines with advanced performance and larger cut sizes can cost more, from $30,000 to $37,000

It is important to note that the initial cost of a press brake is only one factor to consider when estimating its value. Other factors to consider include the machine’s reliability, ease of use, and output quality, as well as ongoing maintenance and operating costs. While the upfront cost of a CNC press brake machine may seem high, it can provide significant cost savings and increased bending efficiency in the long run, especially for high-volume and precision cutting applications.

If you are considering buying a 63 Ton 2000MM CNC press brake machine, you can contact us. SC SHENCHONG, as a professional cnc press brake manufacturer, can not only provide you with a competitive price but also provide you with perfect customer support and warranty.

The maximum thickness that a 63 ton 2000mm CNC press brake machine can bend depends on the type of material being bend and the sheet plate length. In general, a 63T 2000mm press brake machine can cut the following materials at most:

- Mild Steel: It can bend mild steel plates with thicknesses 3mm and the plate length 2000mm.

- Stainless Steel: 63 tons 2000mm press brake can bend stainless steel plate thickness 1.2mm with length 2000mm.

- Aluminum: It can bend aluminum plates with thicknesses 4mm and the plate length 2000mm.

It is important to note that these thicknesses are general guidelines and may vary by specific machine and application.

Request Informations

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.