Table of Contents

Introduction

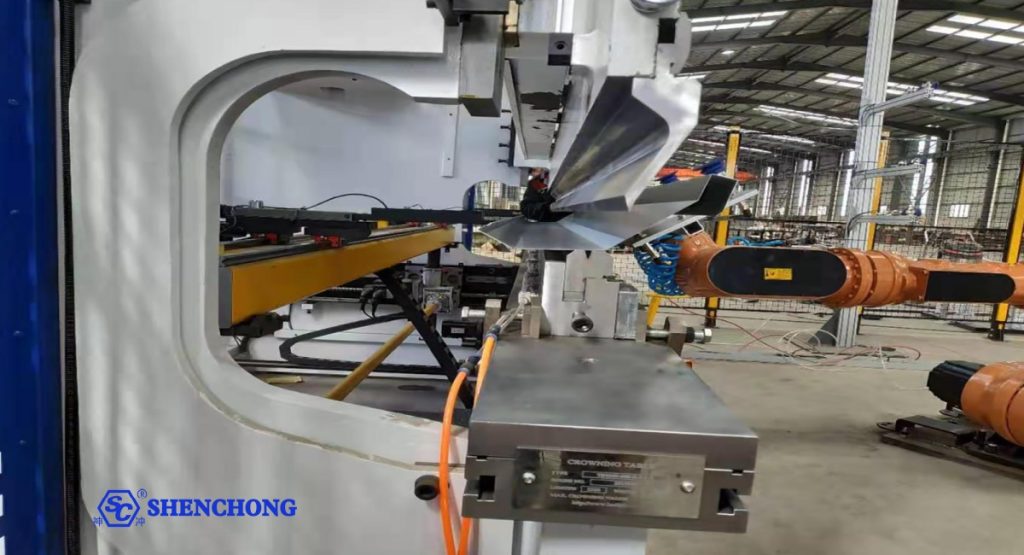

The advent of robotics in manufacturing has revolutionized the press brake industry, introducing robotic press brakes that automate the metal bending process. A robotic press brake integrates a traditional hydraulic press brake machine or servo hybrid press brake with a robotic arm, enabling precise and efficient operations while reducing manual labor and production errors. However, as with any advanced technology, robotic press brake price is a significant factor for businesses.

In this comprehensive article, we will explore the various factors that influence the robotic press brake price, including the machine specifications, automation levels, software, and additional accessories. We will also provide a breakdown of costs associated with installation, maintenance, and the operational benefits that justify the investment. Finally, we will discuss market trends and the future of robotic press brakes.

Overview Of Robotic Press Brakes

A robotic press brake consists of a standard press brake integrated with an industrial robot to automate the loading, positioning, and bending of materials. This type of automation is designed to increase productivity, improve accuracy, and reduce human error in metal fabrication processes.

While traditional CNC press brakes require skilled operators to manually handle the material and operate the machine, robotic press brakes automate the bending process, allowing for continuous production with minimal human intervention. The addition of robotics offers several benefits, such as:

- Increased productivity: Robots can work faster and more consistently than human operators, increasing production speed.

- Improved precision: Robots reduce errors and ensure repeatability in the bending process, resulting in higher-quality products.

- Reduced labor costs: Automation minimizes the need for manual labor, reducing costs and the potential for human error.

However, these advantages come with an upfront investment, and the cost of a robotic press brake can vary greatly depending on several factors.

Factors Affecting The Price Of A Robotic Press Brake

The cost of a robotic press brake is influenced by several key factors, including the size and capacity of the press brake, the type of robot used, the level of automation, software, and additional features. Below are the main elements that impact pricing.

Press Brake Specifications

The specifications of the press brake itself are a primary determinant of the overall cost. Key features include the tonnage capacity, bending length, and the type of press brake (hydraulic, electric, or hybrid).

Tonnage Capacity: The tonnage refers to the maximum force the press brake can apply when bending material. Higher tonnage capacity machines are generally more expensive due to the additional power and structural strength required. A press brake with a 100 ton capacity may cost significantly less than one with a 500 ton capacity.

Bending Length: The length of the press brake’s working table determines the maximum size of the material that can be bent. Machines with longer working table (e.g., 3-6 meters) are more expensive as they require larger and more powerful components.

Type of Press Brake:

- Hydraulic press brakes: Typically less expensive but slower and less energy-efficient.

- Electric press brakes: Faster, more precise, and energy-efficient but come at a higher price point.

- Hybrid press brakes: Combine the benefits of hydraulic and electric machines, balancing cost and efficiency.

Type Of Bending Robot

The type of robot integrated into the press brake system plays a crucial role in determining the price. Several factors influence the cost of the robotic arm, including payload capacity, reach, precision, and the brand or manufacturer of the robot.

Payload Capacity: Robots with higher payload capacities (e.g., 50-100 kg or more) are more expensive. This capacity is important for handling larger and heavier materials.

Reach and Range of Motion: Robots with a longer reach and a wider range of motion tend to cost more, as they can handle larger parts and perform more complex movements.

Brand: Well-known brands such as Fanuc, ABB, and KUKA tend to have higher prices compared to lesser-known brands due to their reputation for reliability and support.

Automation Level

Robotic press brakes come with different levels of automation, from basic robotic integration for material handling to fully automated systems that handle multiple operations, including loading, unloading, and stacking.

Basic Automation: Systems that only automate part of the process, such as material loading and unloading, are generally more affordable. These systems require human intervention for setup and programming.

Fully Automated Systems: High-end systems offer full automation, including advanced features like automatic tool changing, real-time monitoring, and adaptive bending. These systems are more expensive but provide significant benefits in terms of speed and efficiency.

Software And Control Systems

The software that controls the robotic press brake is another significant cost factor. Modern press brake systems come with advanced CNC (computer numerical control) and CAM (computer-aided manufacturing) software that allows for precise programming and control of the bending process.

CNC Software: Press brakes are typically equipped with CNC controllers that automate the bending process based on programmed parameters. Advanced CNC systems with multi-axis control and touch-screen interfaces are more expensive.

Offline Programming: Some robotic press brakes come with offline programming software, which allows operators to program the machine without stopping production. This increases efficiency but adds to the cost of the system.

Additional Accessories and Features

Additional accessories, such as safety systems, automation modules, and specialized tooling, can also increase the price of a robotic press brake.

Safety Features: Automated press brake systems require advanced safety features such as light curtains, laser sensors, and automatic shutdown systems to protect workers and prevent accidents. The cost of these safety features can add significantly to the overall price.

Tooling: Press brakes require specialized tooling for different bending operations. Custom or precision tooling is more expensive but necessary for complex bending processes.

Automation Modules: Some systems come with additional automation modules such as tool changers, palletizers, and conveyors, which increase efficiency but also add to the overall cost.

Cost Breakdown Of A Robotic Press Brake

To provide a clearer picture of the total cost, let’s break down the price components of a typical robotic press brake system.

Press Brake Machine And Robot Price

The base price of a robotic press brake system typically includes the press brake machine itself and the robotic arm. Prices vary widely depending on the capacity and features of the system:

- Press Brake Machine: $50,000 to $300,000, depending on the tonnage, bending length, and type (hydraulic, electric, or hybrid).

- Robot: $50,000 to $150,000, depending on the brand, payload capacity, and range of motion.

Software Price

Advanced software for controlling the press brake and robotic arm is a significant cost component:

- CNC Controllers: $5,000 to $30,000, depending on the complexity and capabilities of the system.

- Offline Programming Software: $10,000 to $50,000, depending on the level of functionality.

Installation And Integration Costs

The installation and integration of a robotic press brake system involve significant labor and engineering work:

- Installation Costs: $10,000 to $50,000, depending on the complexity of the system and the level of customization required.

- Integration and Setup: $20,000 to $100,000, depending on the level of automation and the need for customization.

Maintenance And Operational Costs

Operating and maintaining a robotic press brake involves ongoing costs related to energy consumption, tool replacement, and servicing:

- Energy Costs: While electric press brakes are more energy-efficient than hydraulic systems, robotic systems still consume a considerable amount of energy, particularly if operating continuously.

- Tooling Replacement: Over time, the tooling used in press brakes wears out and needs to be replaced. The cost of tooling varies depending on the material and complexity, typically ranging from $1,000 to $20,000 per set.

- Maintenance and Service Contracts: Routine maintenance and service contracts are essential to keep the system running efficiently. These costs range from $5,000 to $20,000 per year, depending on the system.

Return On Investment (ROI) And Cost Justification

Despite the high upfront cost, a robotic press brake offers significant long-term savings and operational benefits. Key factors that justify the investment include:

Increased Productivity

A robotic press brake can operate continuously without fatigue, allowing for increased production rates compared to manual operation. This leads to a higher throughput and faster return on investment, especially in high-volume manufacturing environments.

Reduced Labor Costs

By automating the bending process, businesses can significantly reduce their reliance on skilled labor, which is becoming increasingly expensive and difficult to find. This reduction in labor costs can offset the initial investment in robotic technology.

Improved Accuracy And Quality

Robotic systems ensure repeatability and precision in the bending process, reducing errors and scrap rates. This leads to higher-quality products and lower material waste, further contributing to cost savings over time.

Flexibility And Scalability

Modern robotic press brakes are highly flexible and can be easily reprogrammed for different jobs, making them ideal for manufacturers with diverse product lines. This flexibility allows businesses to scale production as needed without investing in additional machines.

Market Trends And Future Outlook

The demand for robotic press brakes is expected to grow as more manufacturers recognize the benefits of automation in metal fabrication. Several trends are shaping the future of the market:

Adoption of Industry 4.0: The integration of IoT (Internet of Things) and smart manufacturing technologies is driving demand for more advanced, connected robotic press brake systems. These systems allow for real-time monitoring, predictive maintenance, and data-driven decision-making.

Labor Shortages: The ongoing shortage of skilled labor in manufacturing is accelerating the adoption of automation, with robotic press brakes offering a solution to this challenge.

Environmental Sustainability: Electric and hybrid press brakes, which are more energy-efficient than hydraulic systems, are becoming increasingly popular as manufacturers seek to reduce their environmental impact.

Conclusion

Robotic press brakes represent a significant investment for manufacturers, but their benefits in terms of productivity, precision, and labor cost savings can justify the upfront cost. The price of a robotic press brake varies widely depending on factors such as machine specifications, robot type, automation level, software, and additional features. As automation technology continues to evolve and the demand for flexible, high-precision manufacturing grows, robotic press brakes will play an increasingly important role in the future of metal fabrication.