30x3000 3 Roller Plate Bending Roll For Sale

SC SHENCHONG W11S upper roller universal 30×3000 3 roller plate bending roll machine is used to make sheet plate into different sharps such as cylindrical form, conic form and arc, it adopted Japan hydraulic technical.

Top roller of the upper roller universal 3 roller plate rolling machine can do vertical and level motion, up and down motion, the position display on the screen. This machine includes pre-bending function.

The down roll fix the height, so material can easily enter the machine and workers operate machine expediently.

30x3000 3 Roller Plate Bending Roll Main Structure

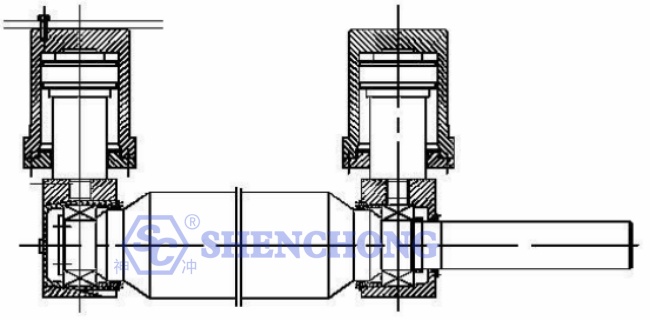

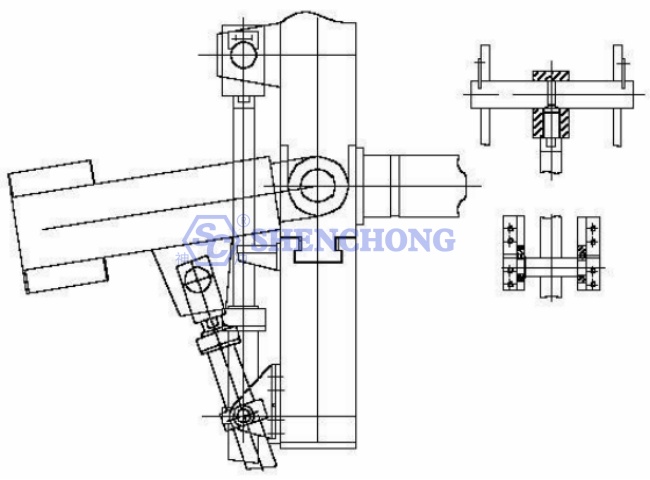

The Upper Roll

Upper roll device composed of main cylinder, upper bearing pedestal, upper roll, double self-aligning bearing. Two cylinders provide the pressure for upper roll bending. Main cylinder working pressure is 20 Mpa, max pressure of upper roll multiply 0.8 times to compensate for pre-bending. Upper roll ends fit with double row self-aligning roll bearing to reduce the friction and motor power. The material of upper roll is 42CrMo, after completion of multiple processes such as forging, tempering, quenching, tempering, stress relieving and precision lathe machining (Note: According to the user’s different needs, the processing procedure of the roll is different); Strictly ensure that the working roll surface strength is high in the rolling plate, the surface of the roll is free from indentation and can meet the requirements of long-term rolled steel plate. Heat treatment is HB250-280, HRC 40-45.

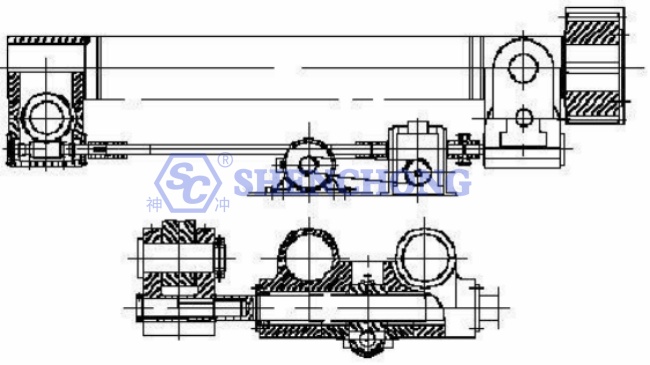

Bottom Roll And Level Motion Device

The material of bottom roll is 45#, heat treatment is HB250-280. It composed of bottom roll, bottom roll bearing pedestal, bottom roll input gear, glide bearing. Bottom bearing adopt SF-2 oil glide bearing.

Level motion motor supply the power, through the strap drive to worm wheel and pole speed reducer. Upper roll level motion drove by worm wheel and pole to finish bending in dis-symmetry form.

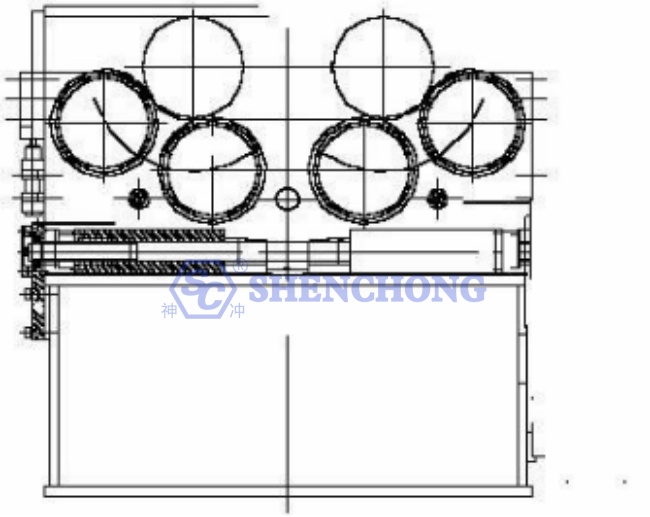

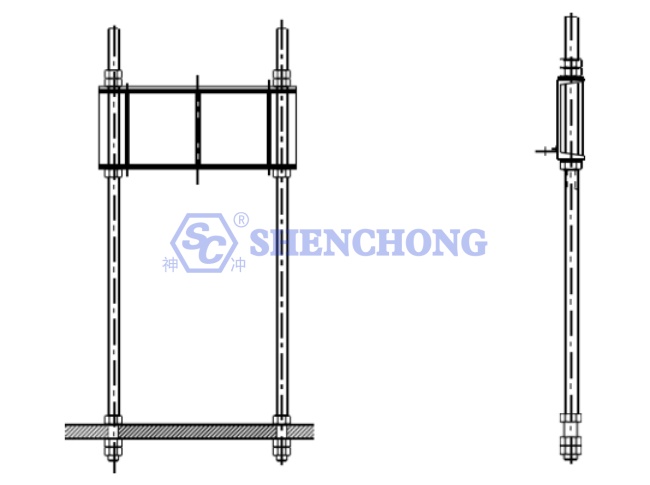

Support Device

30×3000 3 roller plate bending roll support deviced is composed of sloping block device, support device, support roll bearing pedestal, support lifting device, support roll can adjust up and down. The adjustment depend on plate specification. The material of support is 45# , heat treatment is HB190-220, it made up in helix sharp to protect the surface.

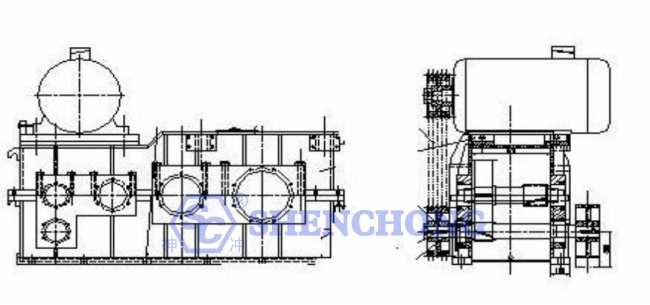

Main Driven Device

Main driven device of a 3 roller plate bending roll is composed of motor, hard gear speed reducer, output gear, main motor can tuning in two direction and provide bending pitch of strand.

Overturn Device

Composed of ram, bearing, tuning cylinder.

Lubricate Device

Composed of lubricate pipe and lubricate pipe attachment, adopted GB7323-1994 NO 2 lithium grease.

Hydraulic System

Composed of Y series motor, gear pump, valves, oil tank, pipe and so on.

Max pressure is 20 Mpa, testing pressure is 24 Mpa, pressure adjusted by overflow valve, system working pressure 0-19 MPa, normal pressure is 15Mpa. The valves is adopted from Taiwan.

Electricity System

Composed of electrical box, operation table, manual button. The power is 380V/50Hz/3PH, it is adopted PLC control system code with longevity easily operate. Whole bending process can read from the indicator setting on the control box.

Technical Parameter

No. | Item | Unit | Specifications |

1 | Model |

| SW11SNC-30×3000 |

2 | Control type |

| Upper roller CNC control display |

3 | Max.pressure of upper roller | Ton | 270 |

4 | Max thickness of rolling plate | mm | T30*B3000*φmin 1200 (σs≤245 MPa) |

5 | Max thickness of pre-bending | mm | T24*B3000*φmin 1200 (σs≤245 MPa) |

6 | Max.width of plate | mm | 3050 |

7 | Yield Strength | Mpa | ≤245 |

8 | Straight edge of pre-bending |

| ≤2~2.5×thickness |

9 | Upper roller diameter | mm | 450 |

10 | Bottom roller diameter | mm | 250 |

11 | Center distance of two rollers | mm | 400 |

12 | Rolling speed | m/min | 4 |

13 | Driving type |

| Mechanical driven by two bottom rollers |

14 | Main power | kw | 30 |

15 | Hydraulic motor power | kw | 11 |

16 | Horizontal moving motor power | kw | 5.5 |

17 | Number of support roller | set | 1 set(4 pieces) |

Configurations

Item | Configuration |

Main low voltage electrical components | Siemens |

PLC programmable controller | SIEMENS/OMRON/HEXIN |

Upper roller | Material 42CrMo alloy steel precision forging parts quality control. |

Bottom roller | Material 45 tempered steel precision forging parts. quenching thickness 9mm. HRC 56. |

Lower pressure cylinder | No. 45 steel conditioning treatment, fine boring inside hole, rolling pressure, yan grinding piston rod no. 45 steel conditioning treatment, outside circle plating nickel phosphorus. |

Sealing ring | NOK, Japan |

Upper roll bearing | Heavy duty roll double row core bearing ZWZ |

Bottom roller bearing | Oilless self-lubricating sliding bearing (SF-2)Wuxi |

The lower roller drives the reducer | Medium hard gear reducer(CZS series) |

Main motor | Wuxi(Crane motor YZR series) |

Hydraulic motor | Wuxi |

Lower roller horizontal moving motor | Wuxi |

Hydraulic system | Homemade valves |

Request Informations

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.