How much is a laser cutting machine? What is the reasonable price? People who is familiar with laser cutting machines gratify that the configuration of laser cutting machines has increased so much now, and the price has decreased compared to a few years ago. There is large price range gap of the laser cutting machine in the market. Facing the chaos of the laser market and intense price competition in China laser cutting market, buyers feel confused about the true price of laser cutting machine.

Below, in this article, I will make a complete laser cutter price research for you. Moreover, I will explain why the laser cutting machine is so high, how to calculate the laser cutting machine price, and how to buy a cost-effective laser cutting machine.

What Is Laser Cutting Machine

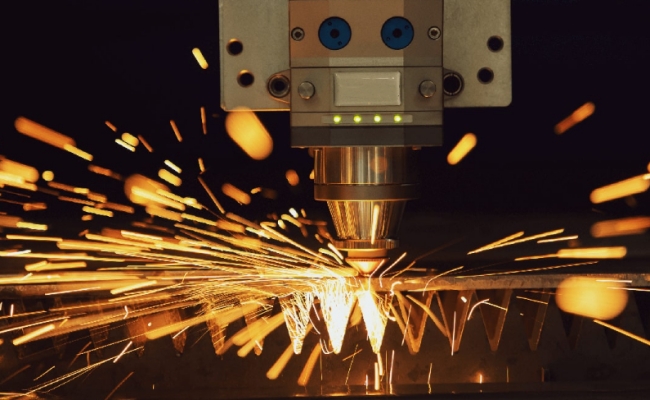

Laser cutting is the process of using lasers to cut metals, plastics, dielectrics, and more, A typical laser-cutting machine combines laser, beam delivery optics, motion hardware to move the part and/or the optics, optional vision system, and integrated control software

Laser cutting machines use a focused or shaped laser beam to act as a precise tool that selectively removes (ablates) material. The ablation process can be photo-thermal (using heat) or photo-ablation (using pressure). depending on the laser parameters and the type of material being cut. Laser cutting can be used to make through-cuts, drill holes, or to scribe-to cut down to a specific depth or material interface. The material can range from thin plastic film to metal several millimeters in thickness. Laser cutting is extremely precise and versatile and is widely used in manufacturing and fabrication.

Laser cutting machine is mainly divided into fiber laser cutting machines, YAG laser cutting machines, and CO2 laser cutting machines. Although they are all laser cutting machine, their prices are different. Even for the same product, various series have price differences. So, what are the factors that affect the cost of laser cutting machines?

Factors Affect The Laser Cutting Machine Price

Many customers will find that the prices of laser cutting machines on the market vary greatly. Even though the configuration is similar, the prices of laser cutting machines of different brands are greatly different. So what does the cost of a laser cutting machine depend on? The cost of a CNC laser cutting machine is determined by the amount of factors, such as the machine manufacture process, area, laser power, and the complexity of machine parts. All these factors must be taken into account when calculating the laser CNC cutter costs.

Laser Cutting Machine Configurations

Laser cutting machines use different components, such as lasers, motors, laser lenses, laser tubes, and control systems, all of these can affect the price of laser cutting machines. Example of SC SHENCHONG:

1. Laser

A laser is a device that can emit laser light. It is the core optical element of a laser cutting machine. According to the working medium, it can be roughly divided into four categories: gas, solid, semiconductor, and dye lasers. The price of laser cutting machines fluctuates greatly depending on the type and capabilities of the laser. Among them, the solid laser is small in size, easy to use, and has a large output power. In addition, the preparation of the working medium is complicated, so the price is more expensive. Gas lasers, especially the most common CO2 lasers, are simple in structure and low in cost. At the same time, it can work stably and continuously for a long time. It is the most widely used type of laser, with a market share of 60%. A laser cutting machine adopted famous brand laser has higher machine price.

2. Electric Motor

The motor is related to the accuracy of the laser cutting machine, and the cost of a branded motor is different from that of a regular branded motor. The accuracy of laser cutting machines may also vary.

3. Laser Lens

The laser lens is related to the power of the laser cutting machine. There is a significant price difference, as well as a significant difference in effectiveness and service life.

4. Laser Tube

This is the core of the laser cutting machine. The brand and quality of laser tubes vary, and the price also varies. The service life of a good laser tube is usually about 3000 hours.

Different Model And Power

The prices of different models (different laser powers, different cutting methods, different machine size) in the same factory may vary. Users need to choose the most suitable power and format size according to their own needs to maximize the use of cutting and bring higher returns to the enterprise value.

The higher the power of the laser, the higher the cost of the CNC laser cutting machine. If you plan to cut metal, tough hardwood, or other dense materials, you need a higher power laser cutter compared to cutting thinner materials such as cloth. For example, fiber laser cutting machine needs about 1kw when cutting carbon steel; 1kw-8kw when cutting stainless steel plate; 1kw-2kw when cutting aluminum alloy; 3kw when cutting brass; 4kw when cutting zinc steel. And CO2 laser cutting machine only needs to choose 30w-300w laser power to cut most non-metallic materials, such as leather, cloth, acrylic, glass, wood, etc.

As above, most of the laser power of fiber laser cutting machine starts at kilowatts, and the price is more than 20,000 dollars. However, the highest power of a CO2 laser cutting machine is only two to three hundred watts, or even tens of watts, and the average price is several thousand dollars. On average, the power of a fiber laser cutting machine is ten times that of CO2, and the price is equivalent to six or seven times the price of a CO2 laser cutting machine.

For the machine format size, 3000x1500mm, 4000mmx2000mm, 6000x2000mm are the normal choosing size, and client can choose the suitable machine format size based on their actual cutting requirement.

Mechanical Assembly Quality

In order to reduce costs, some laser cutter manufacturers use thin iron sheets to make machine frame and cover, which users usually cannot see them. But over time, the frame will deform, affecting the cutting accuracy of the laser cutting machine. A good laser cutting machine should be made of a strong frame structure, welded with high-quality steel, and made of high-quality cold-rolled steel plates for the outer shell. When users purchase a machine, see if quality can be found by using the frame structure, thickness and strength of the outer shell iron.

Extra Fees - Protective Cover of Laser Cutting Machine

What is the protective cover laser cutting machine? It is a kind of laser cutter with a protective cover designed for people with higher environmental requirements. A fully protected laser glass cover ensures safer operation and protects the environment. Its price is slightly higher than normal laser cutting machine, which cost about $5,000-$10,000 higher. And the overall fiber laser cutting machine with protective cover price ranges from $20,000 to $100,000.

The laser cutting machine equipped with a protective cover is expensive because it has many advantages.

First of all, the full protective cover is designed and manufactured with special stainless steel materials, which ensures the robustness and durability of the protective cover.

Second, when the fiber laser cutting machine cut and engrave materials, due to the good air tightness of the protective cover, the generation of noise is avoided.

Thirdly, some dust particles from the outside are blocked, ensuring that the fiber laser cutting machine is not affected by external environmental factors.

Fourth, the dust generated by cutting will not leak out, and the cleanliness of the workshop can be ensured. Therefore, a laser cutting machine equipped with a safety shield is more expensive than an unequipped laser cutting machine.

New Or Used Laser Cutting Machine

New machines are definitely expensive. Your choice reflects on laser cutting price. So would a used one be a good alternative?

This is again a question that does not have a right or wrong answer. Is it worth the risk? Depends.

Used laser cutting machine is much cheaper than a new laser cutting machine. However, new machinery also means new technology, resulting in quicker turnaround times and more profit.

So it may be wise to consider what do you need the laser for – is it for fulfilling your basic cutting needs or does your business depend on it?

Though the developed countries also have a lot of people who intend to purchase a used laser cutting machine for the attractive low cost, second-hand cutting machine for sale has more often been seen in developing countries. The used laser cutting machine price is several thousand dollars cheaper than the new laser cutting machine price.

Shipping Cost And After-Sales Service

Laser cutting machine price in America, laser cutter cost in Australia, laser cutting machine price in the UK, or laser CNC cutter for sale in India definitely are very different from each other. Because the distance between different countries has a big difference, so customers will according to the actual situation choosing different transportation methods. At the end, the shipping freight will be very various. At the same time, whether you choose to LCL, disassembly, or transportation of the whole machine, they all affect the freight price. In addition, there may be other additional fees, such as training fees, technical support fees, etc.

Purchasing large laser cutting machine, after-sales service is a crucial issue. Comprehensive services can ensure the safety and timely maintenance of user equipment. The laser tube and reflector of the laser cutting machine are consumables with a certain service life and need to be replaced after expiration. This requires manufacturers to provide strong after-sales service guarantees and timely provision of these consumables. Different manufacturers have their own advantages and disadvantages in after-sales service. So there will be price differences.

Laser Cutting Machine Functions

Users should pay more attention to the cost-effectiveness of laser cutting machines. The laser cutting machine with reasonable configuration and reasonable price is the best choice. Many users may have misunderstandings that they hope to buy the laser cutting machine with “comprehensive” functions. Anything can be done with a laser machine, which is actually incorrect.

There are different series of laser cutting machine in the market: metal sheet laser cutting machine, tube laser cutting machine, sheet and tube laser cutting machine, uncoiling laser cutting machine and even automatic loading unloading laser cutting machine, and all of these series have different price range.

How Much Is A Laser Cutting Machine

Following is the price range of these several laser cutting machines. But it is for reference only. The final laser cutting machine for sale price will be determined by the actual situation.

- Wood laser cutting machine price $3,000-$9,500

- Acrylic laser cutting machine price $5,400-$15,000

- Fabric laser cutting machine price $6,000-$16,000

- MDF laser cutting machine price $5,600-$14,500

- Metal laser cutting machine price $15,000-$100,000

Non-Metal Laser Cutting Machine Price

Wood, acrylic, fabric, and MDF are all belonged to non-metal materials. Seeing from the above price table, it is clear that the non-metal laser cutter cost ranges from 3,000 dollars to 16,000 dollars. And most of them are less than ten thousand dollars. They are laser cutters with good quality and low price. It is widely used in clothing, leather, cloth toys, models, crafts, advertising decoration, packaging printing, and other industries.

Metal Laser Cutting Machine Price

Metal laser cutting machine is the hottest cutting machine in the sheet metal processing industry. However, how much is a laser cutting machine? What price is reasonable? If you are looking for the metal cutting machine price, or tube laser cutting machine price, here are three typical metal laser cutting machines for sale. They are metal sheet laser cutting machine, metal tube laser cutting machine, and double-use sheet and tube laser cutting machines. For the former two kinds of laser metal machines, you can purchase within 100 thousand dollars based on the laser power and machine format size. While the tube and sheet laser cutting machine may be purchased by more than ten thousand dollars or even higher. By the way, the tube laser cutting machine price is a little higher than the sheet laser cutting machine price since steel tube is more complex to cut and engrave. Cutting tube needs 3D processing.

Two Major Laser Cutting Machine Price

- Fiber laser cutting machine price $25,000-$95,000

- CO2 laser cutting machine price $3,000-$16,000

Differences Between Fiber Laser Cutting Machine And Co2 Laser Cutting Machine

Different Luminescent Media

Fiber laser is generated by diode pumping, and the laser beam is transmitted using flexible fiber optic cables. CO2 laser is generated by exciting nitrogen and carbon dioxide gas in the cavity, and then transmitted through a reflector. Fiber laser is a new type of fiber laser developed internationally, which outputs a high-energy density laser beam and gathers it on the surface of the workpiece, causing the area illuminated by the ultra-fine focal spot on the workpiece to instantly melt and vaporize. By moving the position of the spot through a CNC mechanical system, automatic cutting is achieved. Compared with bulky gas lasers and solid lasers, gas lasers have obvious advantages and have gradually developed into important candidates in fields such as high-precision laser processing, LiDAR systems, space technology, and laser medicine.

Different Structures

At the same power, fiber lasers have a more compact structure compared to CO2 lasers.

Different Electro-Optic Conversion Efficiency

The conversion efficiency of a typical CO2 laser is about 10%, while that of a fiber laser is about 30%.

Different Laser Wavelengths

The wavelength of fiber laser is 1.06 μ m. The wavelength of CO2 laser is 9.3 μ M~10.6 μ m. Therefore, the focusing spot of fiber laser is smaller than that of CO2 laser, with faster cutting speed and higher processing efficiency.

How Much is A Laser Cutting Machine - Fiber Laser Cutting Machine Price

According to different cutting functions and cutting materials, fiber laser cutting machines can be divided into the following several metal laser cutters. The following is the price range of these fiber laser cutting machines, for reference only.

Fiber Laser Cutting Machine Model Price Range

- Sheet fiber laser cutting machine $15,000-$50,000

- Tube fiber laser cutting machine $15,000-$50,000

- Metal sheet and tube fiber laser cutting machine $20,000-$60,000

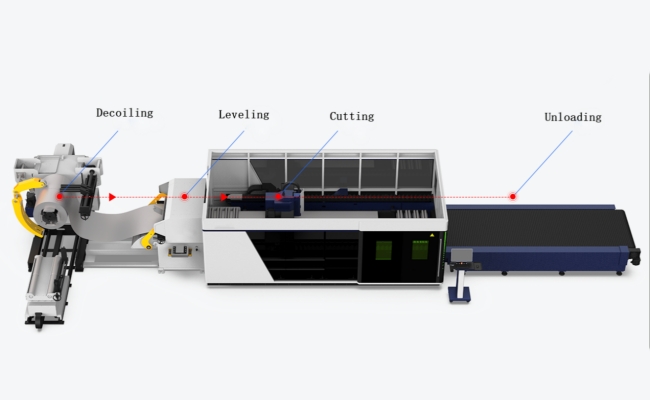

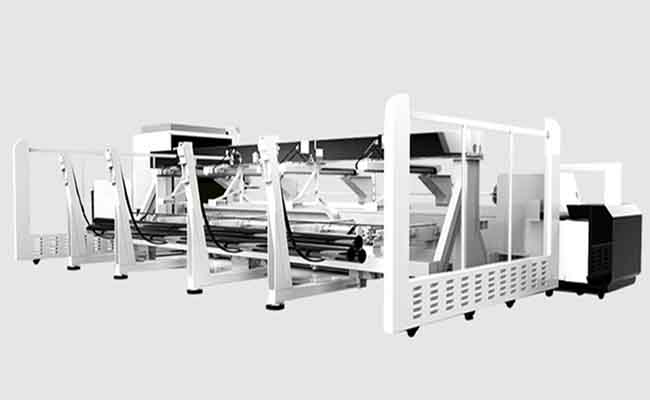

- Automatic coil fed fiber laser cutting machine $45,000-$95,000

The dual-use laser cutter can perfectly cut both metal sheets and metal tubes. It combines two functions in only one machine, which will save a lot of space. Moreover, it can also extend the laser cutter design types and help you produce more different laser projects for sale.

Automatic coil fed fiber laser cutting machine has very high automation. It adopts a support roller, which rotates to feed the metal sheet at a regular cutting speed. This machine is specially designed for thin metal sheets and its bearing capacity can reach up to 10T.

CO2 Laser Cutting Machine Price

The price of a CO2 laser cutting machine is much cheaper than that of a fiber laser cutter. Generally, the small size CO2 laser cutter price is about $3,000-$9,000, such as the 960 CO2 laser engraving machine or the 1390 CO2 laser cutting machine. But for a larger size laser cutter with a working area of 1300*2500mm or 1300*2600mm, they may cost about $6,000-$15,000. For instance, the 1326 acrylic laser cutting machine price is sold at about 8,000 dollars.

Conclusion

Laser cutting machine price has always been a concerning topic in the current cutting machine market. Especially those novice buyers, they are more concerned about the cost of laser cutting machine for sale. For example, how much is a laser cutting machine? What will affect the laser cutting router machine price? Where can I buy a cheap laser cutting machine? Questions of this kind are endless. This article introduces the factors affect the laser cutting machine price and list the price range of both different types of laser cutting machines.