Press Brake Tonnage Calculator

In recent years, press brake machines have been widely used in various industries, and the press brake processing range is also expanding day by day. However, there is no systematic discussion on the calculation of bending force. In this article, we will explore the original calculation formula of bending force, learn the factors affect press brake tonnage calculator and understand how to avoid the overestimate or underestimate tonnage.

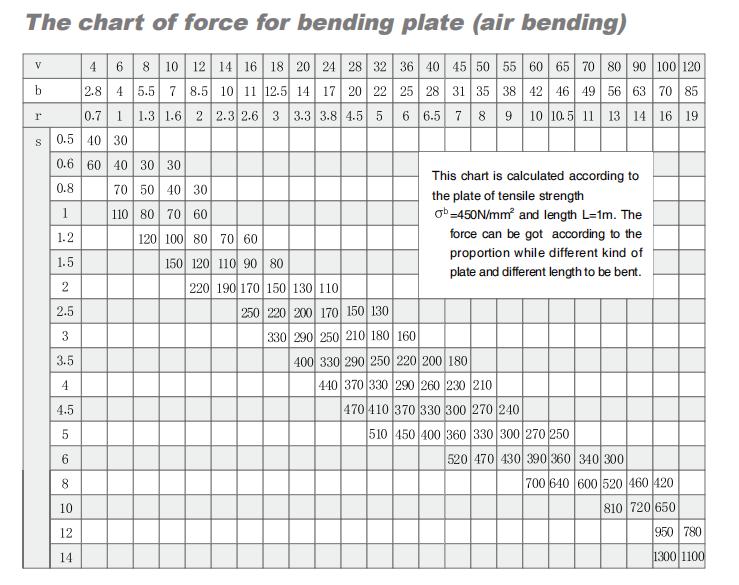

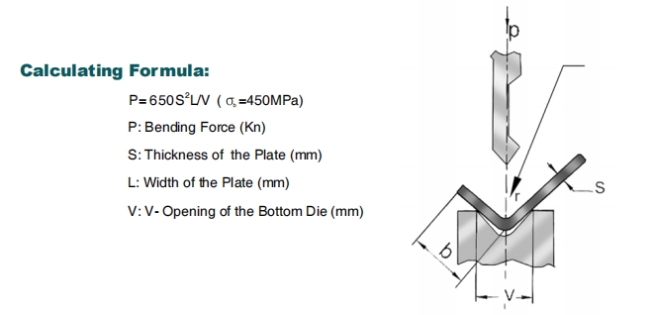

Formula for Press Brake Tonnage Calculator

P= 650*S²*L/V

P: bending force (KN)

σb :Material tensile strength, N/mm (standrad σb = 450Mpa)

t: sheet thickness (mm)

V: Lower die opening width (mm)

L: sheet length (M)

Calculation Example

Mild steel sheet thickness is 3mm, plate length is 2000mm, what is the press brake tonnage should choose?

P=650*3²*2/(3*6)=650KN=65tons

Why here V=3*6? Following article will introduce how to calculate the V opening of the press brake bottom die.

Factors Affecting Press Brake Tonnage Calculation

Recommended V Opening Of The Bottom Die

First of all, the V opening of lower die affects the press brake tonnage calculation. The V opening of the press brake lower die is generally related to the material thickness. According to market requirements, for sheet metal with a thickness (t): 0-3mm, the width of the V groove of the press brake bottom die is V = sheet thickness (t) * 6; and for precision bending, this coefficient can narrow from 6 to 4 . For sheet metal with thickness (t): 3-10mm, the width of the V groove of press brake lower die is V= plate thickness (t) * 8. For sheet plate with thickness (t) of 10mm or more, the width of the lower die groove V= plate thickness * 10 or 12, as shown in the table below.

Sheet Plate Thickness (mm) | 0-2.5mm | 3-8mm | 9-10mm | above 12mm |

V Opening Of Lower Die (mm) | 6*t | 8*t | 10*t | 12*t |

Tensile Strength Of Commonly Used Materials

Secondly, different material tensile strength also affects the calculation of press brake tonnage calculator. The symbol for tensile strength is Rm (GB/T228-1987 old national standard stipulates that the tensile strength symbol is ob), and the unit is MPa (note: N/mm -=MPa).

Aluminum: 200-300 N/mm

Mild Steel:370-500 N/mm (usually 450 N/mm)

Stainless steel: 650-700 N/mm

To simply the press brake tonnage calculation, we usually firstly calculate the mild steel tonnage, then time related rates.

Aluminum = mild steel tonnage * 0.5

Stainless steel = mild steel tonnage * 1.5

Calculation Example

Stainless steel sheet thickness is 3mm, plate length is 2500mm, what is the press brake tonnage should choose?

P=650*3²*2.5/(3*6)*1.5=1219KN=122 tons

What is tensile strength?

Tensile strength is the critical value at which a metal transitions from uniform plastic deformation to localized concentrated plastic deformation, and it is also the maximum load-bearing capacity of a metal under static tensile conditions. The tensile strength represents the resistance of a material to the maximum uniform plastic deformation. Before bearing the maximum tensile stress, the deformation of the tensile specimen is uniform and consistent, but after exceeding this limit, the metal begins to exhibit necking, resulting in concentrated deformation; For brittle materials with no (or very small) uniform plastic deformation, it reflects the fracture resistance of the material. It can also be understood as: when the steel yields to a certain extent, its resistance to deformation increases again due to the rearrangement of internal grains. At this time, although deformation develops rapidly, it can only increase with the increase of stress until the maximum stress is reached. Afterwards, the ability of the steel to resist deformation significantly decreased, and significant plastic deformation occurred at the weakest point. At this point, the cross-section of the specimen rapidly shrank, leading to necking and fracture failure. The maximum stress value of steel before tensile fracture is called the ultimate strength or tensile strength.

Thickness Of Sheet Plate

Thirdly, as users known, plate thickness is one of the most critical factor that determines the bending force. The thickness of sheet plate is one of the most important factor affects the press brake tonnage calculation. Generally speaking, under the same processing conditions, the thicker of the plate to be bent, the greater the unit pressure required to deform it, and so the larger press brake machine tonnage is required.

Length Of Sheet Plate

Fourth, length of sheet plate is another key point in the press brake tonnage calculator. Longer the plate length, larger bending force the press brake required.

Sometimes, operator need to pay attention to the unit bending force. For example, the user usually bend mild steel plate thickness 3mm, plate length 3000mm; but at the same time, he also needs to bend mild steel plate thickness 8mm, plate length 1000mm. In this case, the unit tonnage of the 3mm thick plate is 3*3*650/(3*6)=325KN, but the tonnage of 8mm thick plate is 8*8*650/(8*8)=650KN. If the user want to use the same press brake to bend these two kinds of plate, the press brake tonnage should be 200T3200MM.

With Hemming Tool Tonnage Calculation For Mild Steel

Fifth, whether using hemming tool or not affects the tonnage calculation. Press brakes with hemming tool need larger bending force and users cannot simply apply the formula. Following is the calculation table for your reference.

1mm thickness 1000mm length mild steel: when it needs to bend with tear drop tooling, it needs tonnage 15 tons per meter. When it needs to bend with full hemming tool, it needs to choose 40Tons/1000mm press brake.

Thickness (mm) | Tear drop (tons/m) | Full hemming (tons/m) |

0.6 | 9 | 23 |

1 | 15 | 40 |

1.5 | 22 | 63 |

2 | 30 | 80 |

2.5 | 55 | 90 |

3 | 77 | 100 |

Poles Bending By Using Heavy Duty Press Brake

Last but not least, bending poles sometimes should consider more factors that not include in the formula. Normally when users choose use tandem press brake to bend the plate, they can use the above formula to calculate the press brake tonnage. However, when they bend polygonal poles with few blades and bend circular arc poles, the press brake tonnage should be much larger than the formula calculation results. Please contact with professional CNC press brake manufacturer to get the suitable machine details.

Allowed Minimum Bending Edge Length

Besides all the factors above, during the bending deformation process, the material on the inner side of the bent corner is compressed and the material on the outer side is stretched, while the material that maintains its original length is distributed in a circular arc. The position of this arc is the material mechanics neutral line of the sheet metal, which is the line used to calculate the unfolded length. It cannot exceed 1/2 of the geometric shape of the plate thickness.

Angle(°) | 165 | 130 | 120 | 90 | 60 | 45 | 30 |

Size (b) | 0.51V | 0.55V | 0.58V | 0.71V | V | 1.31V | 1.94V |

Overestimating Tonnage

Users sometimes think if they buy large tonnage press brake, they can bend all of small workpieces that covered by the tonnage requirement. As the professional press brake factory, we need to say this is the common misunderstanding. By using the press brake tonnage calculator without consult with the manufacturer, users often overestimate tonnage or underestimate tonnage.

The Risks of Using Too Much Tonnage

Bad Bending Effects For Small Workpieces

When user bend small workpieces by using large tonnage press brake, they will find that the press brake tooling designed for large press brake are not suitable to bend the small work-pieces. Large press brake usually use multi-V press brake lower die and its V notch is too large for thin sheet plate. Even users change the small bottom die for thin plate, the large tonnage press brake with wide working table sometimes obstructing bending effects.

Unnecessary Energy Consumption

Using larger tonnage press brake means need to use more electric power. If the users always use large press brake to bend small workpieces, they spend money on unnecessary energy consumption.

Tips for Avoiding Overestimation

- Contact with press brake factory to choose the most suitable machine model.

- Use small press brake to bend small workpieces and use large press brake specially for large workpieces.

- Choose to buy hybrid servo press brake to reduce the energy consumption.

Underestimating Tonnage

Underestimating tonnage is another common problem in the press brake selection process. Some users use press brake tonnage calculator online to calculate the tonnage by themselves, but the tonnage affects by many different factors as we discuss above. Below we talk about the risk of underestimating the press brake tonnage.

Potential Issues with Using Insufficient Tonnage

Using insufficient press brake tonnage to bend plate has larger risk than using overestimating press brake tonnage to bend thin plates. Below are two main risks.

Not Able To Bend

When the users buy the insufficient tonnage press brake to bend the plate exceeds the bending capability, the most intuitive problem is that the machine cannot bend the required angle. For example, use the insufficient tonnage press brake machine to bend the required 90°, no matter how the users adjust the CNC controller, the bending result may shows the machine can only bend 120°.

Broken

Another problem for using insufficient tonnage press brake is that the press brake tooling or the machine may broken during the bending process.

Use the example above: the user usually bend mild steel plate thickness 3mm, plate length 3000mm; but at the same time, he also needs to bend mild steel plate thickness 8mm, plate length 1000mm. If user choose correct machine model, he should buy 200T3200MM. However, if he only buy 100T3200MM based on the 3mm thick 3000mm plate bending, when he bend 8mm thick 1000mm length plate, the press brake tool may broken or he cannot get the required angle.

Conclusion

From this article, we firstly introduce the formula commonly used in press brake tonnage calculator and the factors affect the calculation, which includes the material tensile strength, V opening of press brake lower die, plate thickness, plate length, hemming tools, poles bending. Besides that, we also discuss the risks of overestimate and underestimate press brake tonnage and how to avoid these potential mistakes. Hopefully, people can learn more about press brake tonnage calculation from this article.