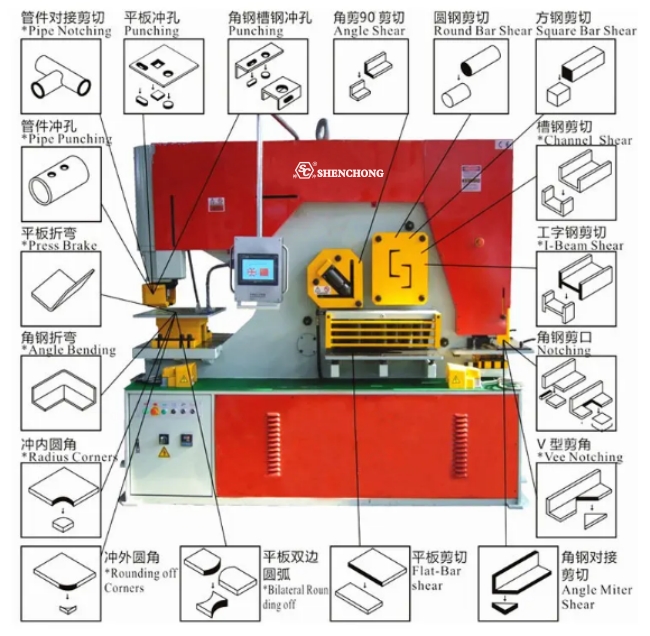

Hydraulic ironworker machine is a machine tool equipment that integrates metal cutting, punching, plate shearing, bending, and other functions. It has the advantages of simple operation, low energy consumption, and low maintenance cost. It is a modern manufacturing industry (such as metallurgy, metallurgy bridge, telecommunications, electric power, military, and other sectors) metal processing equipment of choice. Ironworker Machine is divided into Hydraulic Ironworker Machine and Mechanical ironworker Machine.

As a professional hydraulic ironworker machine factory, SC devoted to furnishing our esteemed clientele with avant-garde solutions that propel productivity and foster efficiency.

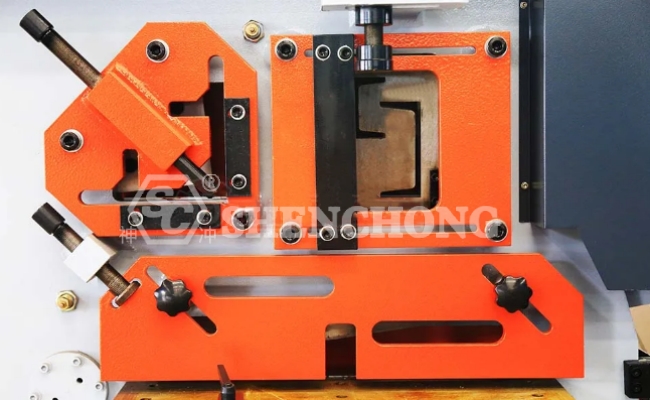

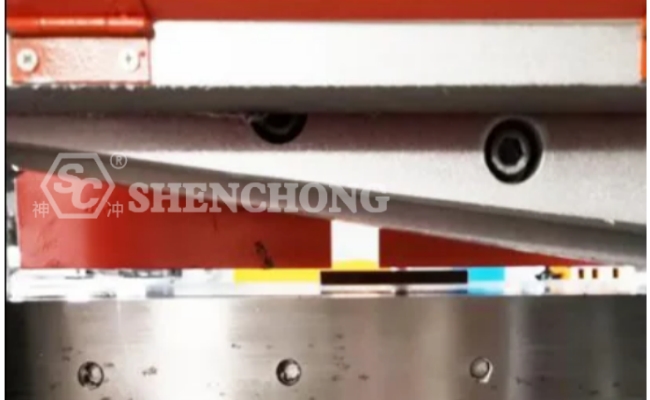

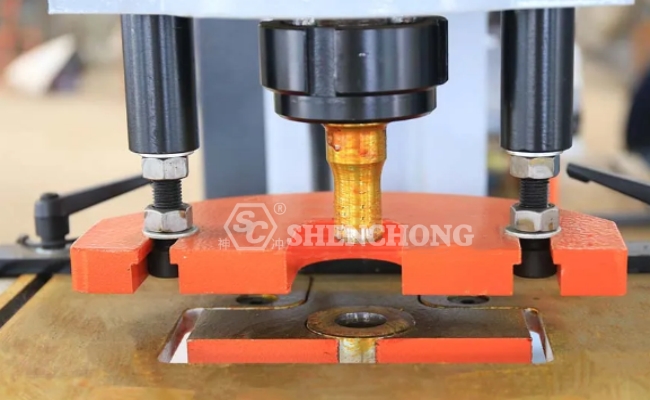

The hydraulic ironworker machine design is exquisite and the structure is stable. Hydraulic transmission and mechanical conventional pressing are adopted.There are five stations, in which a is an independent station and BCDE is a combined station. The stroke of punching and shearing is adjustable.Different cutters can be selected to cut,punch,cut,chamfer and die shear flat steel, square steel, round steel bar, angel steel, channel steel, I-beam, Z-beam and other common solid steel materials.The worktable is equipped with T-groove and ruler,which is convenient for free installation and adjustment of tooling and die.Double foot switch, free and independent operation,double efficiency.

The Hydraulic ironworker adopts hydraulic transmission. It is the latest product of the domestic multi-functional combined punching and shearing machine. It can cut, punch, die cut flat steel, square steel, round steel, angle steel, channel steel, and I-beam. Equipped with shear stop device. It is a machine tool that integrates multiple functions such as metal shearing, punching, plate shearing, bending, etc. It has the advantages of simple operation, low energy consumption, and low maintenance cost.

The structure includes:

* Punching station

* Section cutting station

* Angle Cutting station

* Shearing station

* Notching station

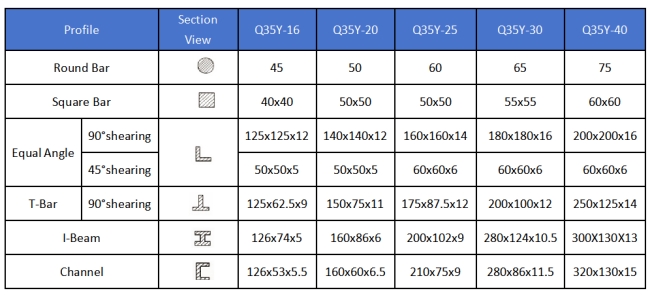

Type | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | Q35Y-40 |

Punching pressure(Ton) | 60 | 90 | 120 | 160 | 200 |

Max.shearing thickness(mm) | 16 | 20 | 25 | 30 | 40 |

Plate strength(N/mm2) | <=450 | <=450 | <=450 | <=450 | <=450 |

Angle of shearing(degree) | 7° | 8° | 8° | 8° | 8° |

Shearing size of one stroke(mm) | 16X250 | 20X330 | 25X330 | 30X335 | 40X335 |

8X400 | 10X480 | 16X600 | 20X600 | 30X600 | |

Ram strock(mm) | 80 | 80 | 80 | 80 | 100 |

Number of stockes(cpm) | 11-20 | 12-20 | 8-18 | 6-16 | 6-16 |

Throat depth(mm) | 300 | 355 | 400 | 600 | 530 |

Punching thickness(mm) | 16 | 20 | 25 | 28 | 35 |

Max.punching diameter(mm) | 25 | 30 | 35 | 35 | 40 |

Power of main motor(kw) | 5.5 | 7.5 | 11 | 15 | 18.5 |

Overall dimensions(L*W*H)(mm) | 1740x810x1830 | 1950x900x1950 | 2355x960x2090 | 2800x1050x2450 | 2900x1100x2500 |

Weight machine (KG) | 2100 | 2800 | 4300 | 6800 | 9800 |

The cutting position of punching and shearing is convenient for cutting various sizes of section steel,and the adjustable pressing device is convenient for cutting other special sections.

Positioning ruler on the worktable can control the cutting shape and cutting length with higher accuracy.

Machine can cut small flat sheets , this function can be used as shearing machine.

The quantity and size of the round or square holes can be customized according to customer’ s requirements .

It shares the same working position with round.

Machine can cut any size of angle steel whose length is smaller than its max. capacity

Hydraulic Angle steel fixing device is optional.

The unique design of die shear part enables the interlock safety protection of angel steel and flat steel processing shear electrical appliances,ensuring the maximum safety of operator.

Punching Die size can be customized , You can tell us your Request , and we will make design and offer you.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.