Brand: SC SHENCHONG

Model: QC11Y NC Plate Shearing Machine

NC Controller: ESTUN E21S

Price Range: $15000-$30000/Set

After Sale: 3 Years

Lead Time: 25-45 Working Day

SC NC plate shearing machine is the hydraulic guillotine shear with NC controller to digital controls the backgauge stroke. With this function, customers cut the plate quickly by NC hydraulic guillotine shear.

At the same time, QC11Y NC plate shearing machine with ESTUN E21S controller can save 50 programs (25 cutting steps), which helps operators quickly call and edit the cutting step programs.

When optimizing product design, SC SHENCHONG adopts dual nitrogen cylinder return stroke for hydraulic plate shearing machine model below QC11Y 16X6000MM, which the machine action is softer, the machine return stroke action is stable, and the noise is lower.

SC SHENCHONG adopts hydraulic cylinder for machine model above QC11Y 16X6000MM, which has large cutting force, can shear sheet plate quickly with perfect cutting result.

|

Model |

Plate Thickness(mm) |

Cutting Length (mm) |

Throat Depth (mm) |

Backgauge Stroke (mm) |

Cutting Angle |

Cutting times/min |

Main Motor(kw) |

Machine Size(mm) |

|

4×2000 |

4 |

2000 |

80 |

600 |

0.5°~2° |

14 |

5.5 |

2600×1680×1750 |

|

4×2500 |

4 |

2500 |

80 |

600 |

0.5°~2° |

14 |

5.5 |

3125×1750×1765 |

|

6×2500 |

6 |

2500 |

80 |

750 |

0.5°~1°30′ |

14 |

7.5 |

3150×1840×1960 |

|

6×3200 |

6 |

3200 |

80 |

750 |

0.5°~1°30′ |

12 |

7.5 |

3850×1840×1995 |

|

6×4000 |

6 |

4000 |

80 |

750 |

0.5°~1°30′ |

10 |

7.5 |

4650×1840×2100 |

|

6×5000 |

6 |

5000 |

80 |

750 |

0.5°~1°30′ |

8 |

7.5 |

5650×2050×2400 |

|

6×6000 |

6 |

6000 |

80 |

750 |

0.5°~1°30′ |

8 |

7.5 |

6650×1980×2380 |

|

8×2500 |

8 |

2500 |

80 |

750 |

0.5°~2° |

14 |

7.5 |

3135×1840×2075 |

|

8×3200 |

8 |

3200 |

80 |

750 |

0.5°~2° |

12 |

7.5 |

3850×1990×2050 |

|

8×4000 |

8 |

4000 |

80 |

750 |

0.5°~2° |

10 |

7.5 |

4650×1890×2075 |

|

8×5000 |

8 |

5000 |

80 |

750 |

0.5°~2° |

7 |

15 |

5650×2050×2400 |

|

8×6000 |

8 |

6000 |

100 |

750 |

0.5°~2° |

7 |

15 |

6805×2115×2715 |

|

10×2500 |

10 |

2500 |

100 |

750 |

0.5°~2°30′ |

10 |

15 |

3195×1915×2205 |

|

10×3200 |

10 |

3200 |

100 |

750 |

0.5°~2°30′ |

8 |

15 |

3895×1900×2235 |

|

10×4000 |

10 |

4000 |

100 |

750 |

0.5°~2°30′ |

6 |

15 |

4695×1970×2450 |

|

10×5000 |

10 |

5000 |

100 |

750 |

0.5°~2°30′ |

5 |

15 |

5700×2115×2715 |

|

10×6000 |

10 |

6000 |

100 |

750 |

0.5°~2°30′ |

5 |

15 |

6905×2115×2800 |

|

12×2500 |

12 |

2500 |

100 |

750 |

0.5°~2°30′ |

10 |

15 |

3195×2000×2210 |

|

12×3200 |

12 |

3200 |

100 |

750 |

0.5°~2°30′ |

8 |

15 |

3895×1950×2240 |

|

12×4000 |

12 |

4000 |

100 |

750 |

0.5°~2°30′ |

6 |

15 |

4710×1950×2485 |

|

12×5000 |

12 |

5000 |

100 |

750 |

0.5°~2°30′ |

5 |

30 |

5750×2115×2800 |

|

12×6000 |

12 |

6000 |

100 |

750 |

0.5°~2°30′ |

5 |

30 |

7150×2300×3100 |

|

16×2500 |

16 |

2500 |

100 |

750 |

0.5°~2°30′ |

8 |

15 |

3215×1970×2340 |

|

16×3200 |

16 |

3200 |

100 |

750 |

0.5°~2°30′ |

7 |

15 |

3915×1970×2455 |

|

16×4000 |

16 |

4000 |

100 |

750 |

0.5°~2°30′ |

6 |

15 |

4715×2010×2590 |

|

16×5000 |

16 |

5000 |

100 |

750 |

0.5°~3° |

5 |

22 |

6000×2300×3000 |

|

16×6000 |

16 |

6000 |

100 |

750 |

0.5°~3° |

5 |

37 |

7250×2400×3100 |

|

20×2500 |

20 |

2500 |

100 |

750 |

0.5°~3° |

6 |

22 |

3235×2020×2465 |

|

20×3200 |

20 |

3200 |

120 |

750 |

0.5°~3° |

5 |

30 |

4150×2065×2755 |

|

20×4000 |

20 |

4000 |

120 |

750 |

0.5°~3° |

4 |

30 |

4955×2125×2885 |

|

20×5000 |

20 |

5000 |

120 |

750 |

0.5°~3° |

4 |

37 |

6000×2300×3050 |

|

20×6000 |

20 |

6000 |

120 |

750 |

0.5°~3° |

5 |

37 |

7150×2450×3280 |

|

25×2500 |

25 |

2500 |

120 |

750 |

0.5°~3.5° |

5 |

37 |

3465×2130×2710 |

|

25×3200 |

25 |

3200 |

120 |

750 |

0.5°~3.5° |

5 |

37 |

4120×2200×3000 |

|

25×4000 |

25 |

4000 |

120 |

750 |

0.5°~3.5° |

4 |

37 |

4950×2200×3150 |

|

30×2500 |

30 |

2500 |

120 |

750 |

0.5°~3.5° |

4 |

37 |

3465×2170×2770 |

|

30×3200 |

30 |

3200 |

120 |

750 |

1°~3.5° |

3 |

37 |

4200×2300×3200 |

|

40×2500 |

40 |

2500 |

80 |

750 |

1°~4° |

4 |

37×2 |

3770×2550×3400 |

QC11YK high speed NC shearing machine is designed for customers who pursue high efficiency and productivity. High speed shearing machine is an updated series of NC hydraulic shearing machine. The cutting speed is twice that of a regular hydraulic guillotine shearing machine, greatly improving work efficiency.

During the high speed shearing process, the deformation of the frame is relatively small, which correspondingly improves the shearing accuracy.

Estun NC-E21S go-to programmable hardened screw back-gauge 750mm travel with fine adjustment.

Side supporter with ruler of plate shearing machine helps to ensure the sheet plate 90 degree feed into the machine.

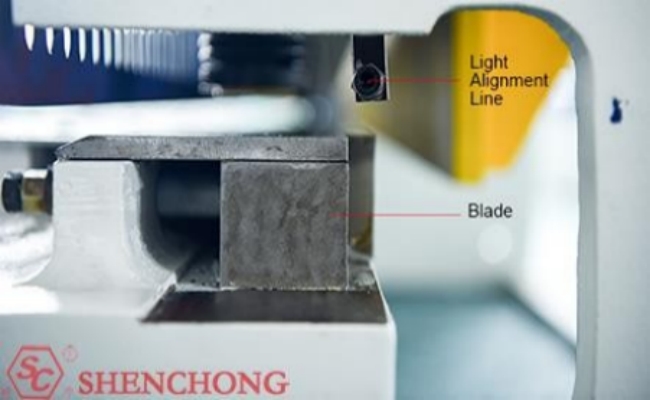

Every set of SC plate shearing machine has the light alignment device as the standard configuration. The light alignment line helps the operator to improve the shearing precision.

SC SHENCHONG adopts electrical cabinet with ABB switch power off as standard configuration to protect the operators.

As a NC hydraulic shearing manufacturer, SC SHENCHONG has more than 25 years plate shearing machine production experience, and we have more than 20 years exporting experience. During the years of design, manufacturing, service, we provide stable high quality NC hydraulic guillotine shear and fast respond after-sale. SC SHENCHONG focus on improve shearing machine types, and we have high speed shearing machine, high precision shearing machine, front feeding plate shearing machine, cnc plate shearing machine, to meet all cutting requirements. Currently we can proudly say that SC SHENCHONG plate shearing machine is No.1 brand in China high-end shearing machine market and we have more than 60% market share in big capacity plate shearing machine.

There are many plate shearing machine factories in China, but why SC plate shearing machine price is much higher than them?

For every 0.01mm increase in accuracy, higher manufacturing costs and more sophisticated manufacturing processes are required. SC SHENCHONG is the leading company in the field of hydraulic guillotine shearing machines, and our engineering team has been constantly improving the quality of the machines. Our machine structure design has always been imitated and never surpassed. SC service team provides you with more professional pre-sales, in-sales, and after-sales quality assurance.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.