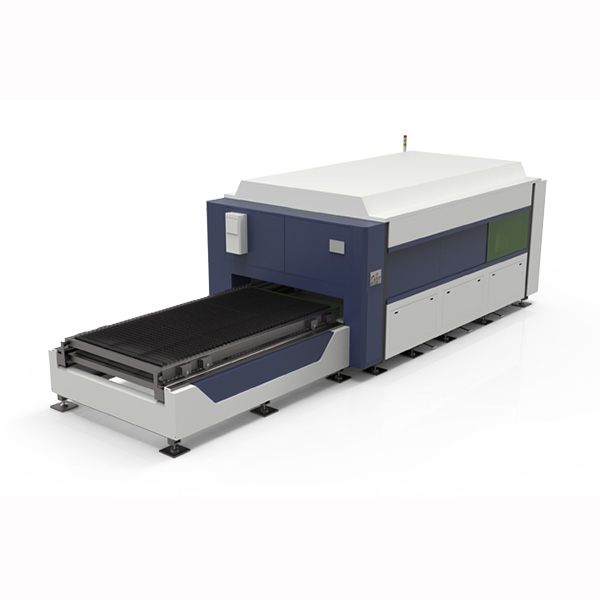

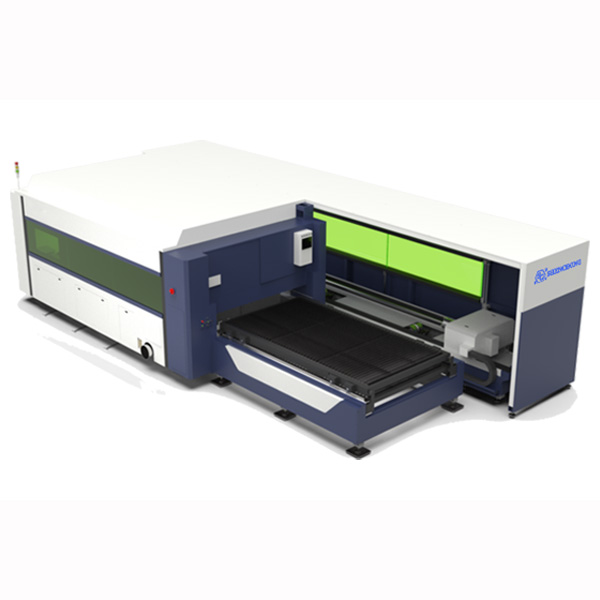

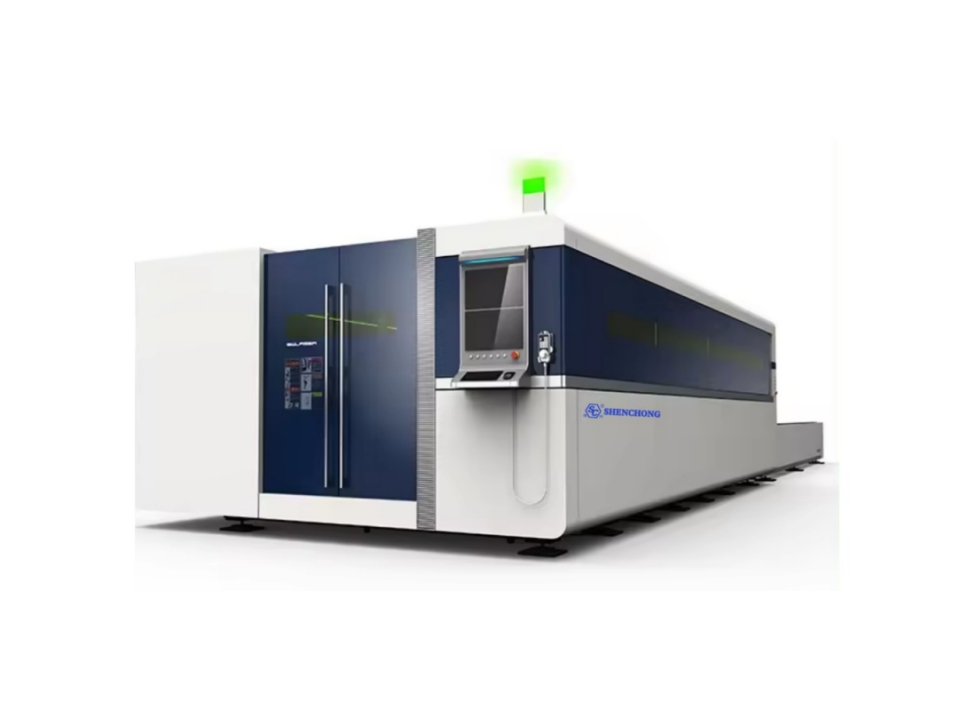

Incredibly fast and flexible, the SC SHENCHONG 3000w sheet metal fiber laser cutting machine for sale is ideal for ultra-high speed cutting of thin sheet materials. SC fiber laser cutter adopts a gantry double tooth gear rack and double servo motor transmission structure with high inertia and large torque output, we greatly and effectively improve your earning efficiency.

SC IPG CNC Sheet Metal Fiber Laser Cutting Machine 3kw For Sale

SC IPG 3000W sheet metal fiber laser cutting machine 3kw price for sale has advantages of high integration, better control precision and more stable operation. Therefore, in addition to the meet the requirement of cutting carbon steel plate, SC IPG sheet fiber laser cutting machine can also meet the requirement of cutting SS plate, aluminum alloy, copper alloy and other materials.

Machine Feature

- User friendly FAGOR 8060 CNC control unit.

- Professional laser cutting software with graphic layout and sharp corner smoothing processing functions to achieve high-speed drilling and fast cutting functions.

- Maximum simultaneous positioning speed: 160m/min.

- Acceleration speed: 25 m/ s2 (2.5G).

- Precision: ± 05 mm.

- Energy efficiency: greatly reduced power consumption.

- IPG YLS-3000w Resonator

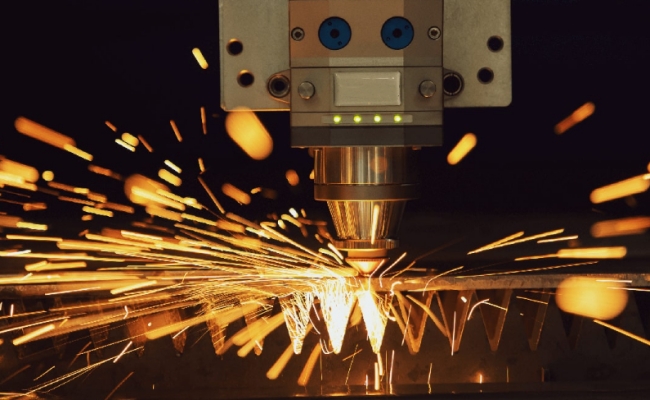

- Advanced PRECITEC cutting head (with air cross blast).

- Precision machining of large gantry machine tools, with annealing and aging treatment to eliminate internal stress, the geometric accuracy of the machine tool is within 0.03mm.

- Fully enclosed and cabinetto ensure maximum operator protection.

- Effective high to low pressure gas exchange system.

- Automatic time and unit cost calculation function.

- Network connection from external.

- Smoke extraction (included in series models).

- Collection of work pieces and trimmings.

- Dual proportional valve control system for different gas pressures and special system for high pressure cutting.

Standard Configuration

- FAGOR 8060 CNC Controller

- IPG YLS-3000W Ytterbium Laser Resonator

- Automatic Double Pallet Changer(Shuttle Table)

- Precision Rack & Pinion Drive System (Made in Germany)

- Radan or Lantek CAD/CAM system

- Light source

- Chiller

- 3 lower protective lenses

- 3 Ceramic Nozzle Adapters

- Auto-calibrated nozzle system

- Lens with 5.9” Focus Length

- Smart Slag Collection System/ Chip Conveyor

- Fiber Beam Transmission System (Fiber Cable)

- Operates with both N2 and O2 (cutting) gases

- Home Position Alignment System

- Auxiliary Gas Selector

- Auto Reflection Warning

- Working Lights

- 5 Nozzles each of the Following: (1.0mm, 1.2mm,1.5mm, 2.0mm , 2.5mm , 3.0mm)

Machine Details

Fiber Laser Generator

The laser source used by the machine is a high-power 3000w fiber laser generator, which is famous for its excellent beam quality, energy efficiency, and long service life. The fiber laser generator is housed in a rugged housing that provides stable and reliable operation even in harsh industrial environments. Client can choose Raycus or IPG for this machine.

Sturdy Machine Body

The internal structure of the body is welded by multiple rectangular tubes, and there are reinforced rectangular tubes inside the body to enhance the strength and stability of the bed. The solid machine body structure not only increases the stability of the guide rail but also effectively prevents the deformation of the bed. The service life of the body is as long as 25 years.

High Precision And Accuracy

The focused laser beam enables extremely fine cuts with extremely narrow kerf widths, minimizing material waste and increasing material utilization. It can achieve cutting tolerances of up to ±0.05mm, ensuring precise and consistent cuts even for complex shapes and contours. The 3000w fiber laser cutting machine also offers flexibility in terms of cutting options. It can perform both high-speed perforation of thick materials and precise high-quality edge-cutting of thin materials. It can also perform bevel cuts to create beveled edges and chamfers.

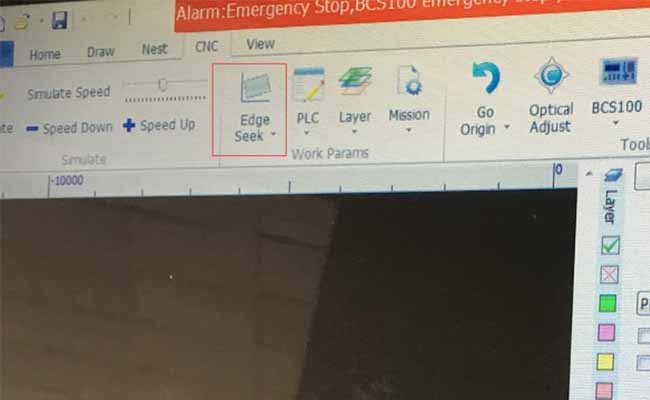

CNC Control System

The machine is controlled by a user-friendly CNC system, which can be easily turned into a synthetically controlled cutting process. The CNC system offers a wide range of cutting parameters that can be set according to the specific material being cut, including laser power, cutting speed, and cutting gas pressure.

Technical Parameter

Model | AKJ-1325 | AKJ-1530 | AKJ-1545 | AKJ-2040 | AKJ-2560 |

Cutting Range | 1300*2500mm | 1500*3000mm | 1500*4500mm | 2000*4000mm | 2500*6000mm |

Laser Type | Fiber laser | ||||

Laser Power | 1kw-30kw | ||||

Laser Generator | Reci/Raycus/IPG | ||||

Maximum Moving Speed | 105m/min | ||||

Maximum Acceleration | 2.5G (25m/s2) | ||||

Positioning Accuracy | ± 0.08 mm | ||||

Repeat Positioning Accuracy | ± 0.03 mm | ||||

Cutting Parameters

Material Type | Thickness (mm) | Speed (m/min) | Focus Position | Cutting Height (mm) | Gas | Nozzle Type | Pressure (bar) | Cutting Effect |

Carbon steel (Q235B) | 1 | 59 | 0 | 0.5 | N2 | Single: 1.0 | 12~16 | Bright surface |

2 | 28 | -0.5 | 0.5 | N2 | Single: 2.0 | 12~16 |

| |

3 | 4 | 4.5~5.5 | 0.8 | O2 | Double: 1.2 | 0.6~0.9 |

| |

4 | 3.5 | 4.5~5.5 | 0.8 | O2 | Double: 1.2 | 0.6~0.9 |

| |

6 | 2.7 | 4.5~5.5 | 0.8 | O2 | Double: 1.2 | 0.6~0.9 |

| |

8 | 2.2 | 4.5~5.5 | 1.5 | O2 | Double: 4.0 | 0.6~0.9 |

| |

10 | 1.5 | 2~3 | 1.5 | O2 | Double: 4.0 | 0.6~0.9 | Matte surface | |

12 | 1 | 2~3 | 1.5 | O2 | Double: 4.0 | 0.6~0.9 |

| |

14 | 0.95 | 2~3 | 1.5 | O2 | Double: 4.0 | 0.6~0.9 |

| |

16 | 0.85 | 2.5~3.5 | 1.5 | O2 | Double: 4.0 | 0.6~0.9 |

| |

18 | 0.72 | 2.5~3.5 | 1.5 | O2 | Double: 4.0 | 0.6~0.9 |

| |

20 | 0.65 | 2.5~3.5 | 1.5 | O2 | Double: 4.0 | 0.6~0.9 |

| |

22 | 0.55 | 2.5~3.5 | 1.5 | O2 | Double: 4.0 | 0.6~0.9 |

| |

25 | 0.5 | 2.5~4 | 1.5 | O2 | Double: 4.0 | 0.6~0.9 |

| |

Stainless steel (SUS304) | 1 | 30~59 | 0 | 0.5 | N2 | Single: 1.0 | 12~16 | No slag |

2 | 19~39 | -0.5~0 | 0.5 | N2 | Single: 2.0 | 12~16 |

| |

3 | 12 | -1.5~-1.0 | 0.5 | N2 | Single: 2.0 | 12~16 |

| |

4 | 4.3 | -4.0~-3.5 | 0.5 | N2 | Single: 3.5 | 12~16 |

| |

6 | 1.8 | -6.0~-5.0 | 0.5 | N2 | Single: 3.5 | 16~18 |

| |

8 | 1.2 | -7.0~-6.5 | 0.5 | N2 | Single: 3.5 | 16~18 |

| |

10 | 0.9 | -8.5~-7.5 | 0.5 | N2 | Single: 3.5 | 16~18 | A small amount of slag | |

12 | 0.4 | -10.0~-9.0 | 0.5 | N2 | Single: 4.0 | 16~18 | A small amount of dross | |

Aluminum (6061) | 1 | 37~40 | 0 | 0.5 | Air | Single: 1.0/1.2/1.5 | 12~16 |

|

2 | 20~22 | -0.5~0 | 0.5 | Air | Single: 1.5/2.0 | 12~16 |

| |

3 | 8~9 | -0.5~0 | 0.5 | Air | Single: 2.0/2.5/3.0 | 12~16 |

| |

4 | 5.0~5.2 | -1.5~-1.0 | 0.5 | Air | Single: 3.0 | 12~16 |

| |

6 | 2.2~2.5 | -3.0~-2.0 | 0.5 | Air | Single: 3.5/4.0 | 12~16 |

| |

8 | 1.0~1.2 | -4.0~-3.0 | 0.5 | Air | Single: 4.0 | 16~18 |

| |

10 | 0.5~0.6 | -5.5~-5.0 | 0 | Air | Single: 4.0 | 16~18 |

| |

Brass | 1 | 22~25 | 0 | 1.5 | Air | Single: 1.0/1.2/1.5 | 12~16 |

|

2 | 18~20 | -0.5~0 | 0.5 | Air | Single: 1.5/2.0 | 12~16 |

| |

3 | 7.0~7.5 | -0.5~0 | 3.5 | Air | Single: 2.0/2.5/3.0 | 12~16 |

| |

4 | 4.0~4.5 | -1.5~-1.0 | 4.5 | Air | Single: 3.0 | 12~16 |

| |

6 | 2.0~2.2 | -3.0~-2.0 | 5.5 | Air | Single: 3.5/4.0 | 12~16 |

| |

8 | 0.9~1.1 | -4.0~-3.0 | 6.5 | Air | Single: 4.0 | 16~18 |

| |

10 | 0.5~0.6 | -5.5~-5.0 | 7.5 | Air | Single: 4.0 | 16~18 |

Frequently Asked Questions

The price of a sheet metal 3000w fiber laser cutting machine can vary greatly depending on the make, model, and specification of the machine. Additionally, prices may also be affected by the country of manufacture, shipping and installation costs, and any additional taxes and charges. Under normal circumstances, the price of a 3000w sheet metal fiber laser cutting machine for sale with basic functions ranges from $18,500 to $80,000. Plus, higher-end machines with advanced performance and larger cut sizes can cost more.

It is important to note that the initial cost of a laser cutter is only one factor to consider when estimating its value. Other factors to consider include the machine’s reliability, ease of use, and output quality, as well as ongoing maintenance and operating costs. While the upfront cost of a laser cutter may seem high, it can provide significant cost savings and increased cutting efficiency in the long run, especially for high-volume and precision cutting applications.

If you are considering buying a 3000w fiber laser cutting machine, you can contact us. SC Laser can not only provide you with a competitive price but also provide you with perfect customer support and warranty.

The maximum thickness that a 3000w fiber laser cutting machine can cut depends on the type of material being cut, beam quality, focus position, and cutting speed among other factors. In general, a 3000w fiber laser cutting machine can cut the following materials at most:

- Carbon steel: up to 25mm

- Stainless steel: up to 12mm

- Aluminum: up to 10mm

- Brass: up to 10mm

- Copper: up to 10mm

- Titanium: up to 10mm

- Nickel: up to 10mm

- Inconel: up to 10mm

It is important to note that these thicknesses are general guidelines and may vary by specific machine and application. It should be noted that the maximum thickness that can be cut will also be affected by the required cutting speed and cutting quality. Slower cutting speeds result in thicker maximum cut thicknesses, while faster cutting speeds may reduce the maximum thickness that can be cut. In addition, as the thickness of the cut increases, the quality of the cut may decrease, resulting in rougher edges or a larger heat-affected zone.

The cutting speed of a 3000W fiber laser cutting machine can vary depending on a number of factors, including the type and thickness of the material being cut, the quality and power of the laser source, the assist gas used, and the parameters and settings of the machine. Here are some typical cutting speeds for different materials when using a 3000W fiber laser cutting machine:

- Carbon steel: For carbon steel with a thickness of 1mm~3mm, the cutting speed can be 4m/min~50m/min. For thicker carbon steel, such as 5mm~10mm, the cutting speed can be between 1.5m/min~3.2m/min.

- Stainless steel: For stainless steel with a thickness of 1mm~3mm, the cutting speed can be from 12m/min to 58m/min. For thicker stainless steel, such as 5mm~10mm, the cutting speed can be between 0.9m/min~5m/min.

- Aluminum: For aluminum with a thickness of 1mm~3mm, the cutting speed can be 9m/min~40m/min. For thicker aluminum materials, such as 5mm~10mm, the cutting speed can be between 0.5m/min~5m/min.

- Copper and brass: For copper and brass with a thickness of 1mm~3mm, the cutting speed can be between 7m/min~17m/min. For thicker copper and brass, such as 5mm~10mm, the cutting speed can be between 0.5m/min~3.5m/min.

- Titanium: For titanium with a thickness of 1mm~3mm, the cutting speed can be between 4.5m/min~8.5m/min. For thicker titanium, such as 5mm~10mm, the cutting speed can be between 0.5m/min~3.2 m/min.

It is important to note that these cutting speeds are approximate and may vary depending on specific machines, materials, and cutting parameters. Cutting speed can also be adjusted according to the desired cut quality, with higher cutting speeds generally resulting in faster production but possibly reduced edge quality. Therefore, it is recommended to consult the machine’s specifications and guidelines and to make trial cuts to optimize cutting speed for specific materials and applications.

Request Informations

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.