3 In 1 Laser Welding Cutting Cleaning Machine 2000W For Sale

3 In 1 fiber laser welding cutting cleaning machine 2000W is a higher cost performance metal welding equipment. lt is a non-contact welding and does not require pressure during the operation with Cutting,welding ,Cleaning in one machine. Easy to Operate and low cost, suitable for outdoor works.

3 In 1 Laser Welding Cutting Cleaning Machine introduction

The 2000w laser welding machine refers to a welding system with a laser output power of 2000 watts. Laser welding is a precise and efficient welding technique that uses a highly focused laser beam to join materials together. It can be used to weld a variety of materials, including metals such as steel, aluminum, and titanium, as well as certain plastics. The high power output allows for deep penetration and fast welding speeds, making it suitable for industrial applications where productivity and quality are critical.

Laser welding allows for fine control of heat input and weld pool size, resulting in precise and accurate welds. A focused laser beam provides a concentrated heat source which minimizes the heat-affected zone and reduces distortion of welded parts. In addition, the power of the laser generator will affect the welding speed. Compared with low-power laser generators, the 2000w laser generator can provide faster welding speed, thus increasing productivity.

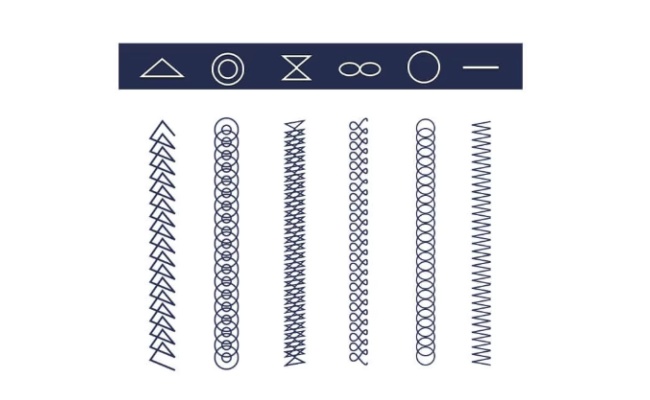

6 Laser Welding Modes

From precise spot welding to continuous welding. choose the most suitable mode, ensure you get the best results and quality every time you laser weld.

3 In 1 Laser Welding Cutting Cleaning Machine Configuration

Laser Generator

Professional welding laser source, small in size, light in weight, and easy to move. The light emitting mode is more conducive to achieving a good welding effect. Support laser powers from 1kw to 3kw.

Laser Head

The laser generated by the laser source is transported to the welding head, then is collected and reflected by a reflector and focused by the focusing lens to reach the nozzles and finally fired to the materials.

Water Chiller

When using an industrial chiller, pure water is used in summer, and antifreeze is used in the water when the room temperature is below 5 degrees Celsius . Switch back to pure water when the temperature warms up.

Wire Feeder

With Standard automatic wire feeding system and dual motors, The forward and reverse and the speed of wire feeding can be adjusted through the control panel. Note: Standard is Single Feeder.

Technical Parameter

Model | SC 3 in 1 Fiber Laser Welding Machine |

Laser Power | 2000W (Option: 1500W, 2000W,3000W) |

Laser Source | MAX (Option: Raycus, IPG, BWT, Reci) |

Laser Welding Head | Raytools, WSX, Au3tech |

Control System | Raytools(Optional:Relfar,Gefasst) |

Support Languages | Chinese Simplified, Chinese Traditional, English, Polish, Turkish, Arabic, Japanese, Korean, German, Spanish, Russian, French,Portuguese, Italian, Hungarian, Czech, Finnish, Vietnamese and so on Customized language accepted |

Cooling Method | Water Cooling |

Auxiliary Gas | Nitrogen or Argon gas |

Note: Cleaning mode can use compressed | |

Range of Adjustable Power | 1-100% |

Laser Wavelength | 1080nm |

Way of Working | Continuous/Modulation |

Positioning Accuracy | ±0.03mm |

Voltage | 220V 1PH 50HZ/60HZ (Option: 110V) |

Package Weight | 260KG |

Welding Thickness Reference

Laser Power | 1000W | 1500W | 2000W | 3000W |

Carbon Steel | 0.5-1.5mm | 0.5-2mm | 0.5-3mm | 0.5-5mm |

Stainless Steel | 0.5-1.5mm | 0.5-2mm | 0.5-3mm | 0.5-5mm |

Brass | 0.5-1mm | 0.5-1.5mm | 0.5-2mm | 0.5-4mm |

1-3 Series Aluminum Alloys | 0.5-1.5mm | 0.5-2mm | 0.5-2mm | 0.5-3mm |

4-7 Series Aluminum Alloys | 0.5mm | 0.5-1mm | 0.5-1.5mm | 0.5-2mm |

Copper | / | 0.5mm | 0.5mm | 0.5-1mm |