SC 2-WEK 700 Ton 4500mm Hydraulic CNC Press Brake Machine With Front Feeding Device

SC Machinery 2x WEK 700 ton 4500mm hydraulic CNC tandem press brake for sale with front feeding device and ESA S630 CNC controller for sheet metal plate bending machine is our most cost effective press brake type for thick plate bending. The CNC hydraulic press brake constructed of high quality parts and offering serious reliability, Y1 & Y2 technology with high approach, bending and return speeds.

To meet customers’ bending requests, SHENCHONG announce WEK Serie Electro-Hydraulic CNC Press Brake, which has become the most popular CNC Press Brake type in the global market.

WEK Serie press brake is equipped with a touch-screen graphic programming CNC controller and is available in 4 axes in total with 2 axes back gauge. WEK Serie is intended and designed for customers looking for the basics and ease of use.

Compared with torsion bar NC press brake, 2x 700T 4500mm hydraulic CNC press brake has higher automation level but almost same machine cost. For this reason, hydraulic CNC press brake is a smart choice for 2x 700T4500MM model.

SC Machinery 2-WEK 700T X 4500MM Hydraulic CNC Press Brake Main Features

- The frame consists of fuel tank, tray, support, work table, left and right wall panels and sliders. The structure, high structural strength and large steel degree ensure the structural strength of the frame and adopt vibration to eliminate stress.

- The structural parts are rusted by shot blasting and sprayed with anti-rust paint.

- Wall panel, slider and workbench are processed by one-time large-scale CNC floor boring and milling machine to ensure the parallelism and verticality of each mounting surface.

- The principle of machine synchronization: the application of electro-hydraulic servo proportional valve to ensure synchronization of the two machines, the use of the German company’s electro-hydraulic servo proportional valve, its performance characteristics are high-operating force continuous action of the electromagnet, the friction of the mechanical movement pair A small precision electronic amplifier with fast operating characteristics. A grid is installed at each end of the vertical plate of the workbench, which continuously reflects the stroke position and synchronization error of the slider and sends the two differences into the microcomputer control system to control the electro-hydraulic servo proportional valve to synchronize the twin-cylinders of each single machine. Since the grating scale is not directly mounted on the frame wall panel, but is mounted on a C-shaped frame fixed to the table vertical plate, and the work table is used as a reference point, the slider itself and the frame are under load. The deformation does not affect the measurement and control accuracy of the scale. The two-machine synchronization of the two-machine linkage transmits the mechanical synchronization information into an electric signal to the synchronizing board and the microcomputer through a differential potentiometer installed between the two sliders, and controls the electro-hydraulic servo proportional valve through the amplifying board to make the dual-machine Synchronous action.

- The operator can directly perform man-machine dialogue through the computer, displaying in Chinese and English, automatically calculating and adjusting the bending force, optimizing the bending sequence, calculating the length of the workpiece, showing the shape and necessary operation information before and after the workpiece is processed, and Automatic calculation control top dead center, speed change point, image display, full-featured, with programming, jog, pressure, slow recovery control and other functions.

2-WEK 700T X 4500MM Press Brake Hydraulic System

- It is driven by electro-hydraulic servo valve group imported by German company. It has compact structure, strong sealing performance, high synchronization precision and long service life.

- External large-diameter filling valve with high speed and low loss.

- Using Sumitomo internal gear high pressure pump can withstand high pressure and low noise.

- The cylinder seal adopts the sealing component of Sweden SKF Company, which has low wear and no leakage.

- The hydraulic system has overload overflow safety protection.

- The cylinder is integrally forged with 45 steel. After rough machining, heat treatment, finishing and fine grinding, the inner wall of the cylinder has both hardness and wear resistance, and high cylindricity precision.

- The plunger is integrally forged by 45 steel. After rough machining, heat treatment and fine grinding, the surface is coated with nickel and phosphorus by the most advanced military technology in the country. The cylinder plunger has good self-lubricating property and can greatly improve the service life.

- The oil level has a clear and intuitive display.

- High-precision guiding system, position measuring system and hydraulic balancing function can meet the needs of full-length machining.

- The equipment can work continuously for 16 hours under the rated load, while the hydraulic system has no leakage and the work is stable and the performance is good. The oil temperature can be controlled within the national standard (≤60~70°C).

2-WEK 700T X 4500MM Hydraulic CNC Press Brake Electrical Control System

- The electrical components comply with international standards, are safe and reliable, have strong anti-interference ability, and the electric control cabinet has heat dissipation function.

- it has a movable foot switch for easy operation and an emergency stop function.

The machine's anti-offset ability

The electro-hydraulic servo system of the machine is a position control system, which dynamically detects the synchronization error of the slider through the grating ruler, and corrects the synchronization error of the slider by the electro-hydraulic servo valve signal given by the numerical control system, so that the slider is completely In the case of partial load, it can always be parallel to the table.

Front Feeding Device

The front feeding device is manually controlled by motor. For large workpieces such as lamp posts and power poles, the electric front feeding device is the most practical and labor-saving.

Machine Details

Safety Protection

Shenchong CNC press brake standard safety protection includes:

Side protection and back door protection

Electrical cabinet with ABB switch power off device

Fan in the electrical box prevent overheating

Cooling device to prevent overheating of oil tank

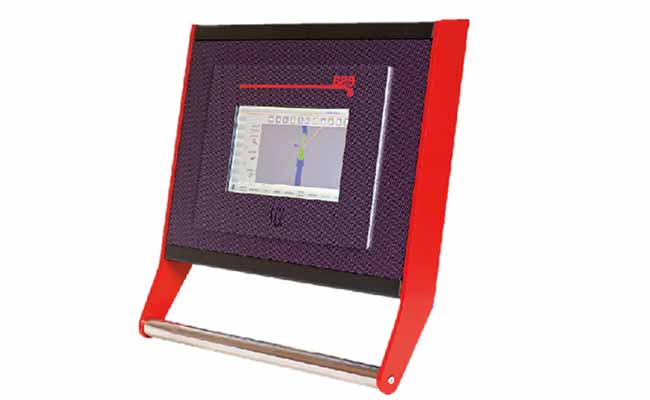

ESA S630 Controller

- Graphic color 10” touch screen display (1024 x 600 pixels resolution).

- 128 silicon disk.

- Interactive 2d graphic editor for work-pieces and tools data entry.

- 2D graphic display of machine frame, work-piece and tools.

- Manual 2D graphic identification of the best bending sequence(option)

- 4 fast counting circuits for line drive 0-5Vdc differential encoders or npn/push pull. The encoders are powered at 5Vdc (max 200mA per channel).

Technical Parameter

Model | 2-WEK-700/4500(ESA-S630) | |||

No. | Item | Unit | value | |

1. | pressure | KN | 2×7000 | |

2. | Working table | mm | 2×4500 | |

3. | Upright distance | mm | 3500 | |

4. | Throat depth | mm | 1000 | |

5. | Ram stroke | mm | 300 | |

6. | Approaching speed | mm/s | 80-160 | |

7. | Working speed | mm/s | 8-12 | |

8. | Return speed | mm/s | 60-120 | |

9. | Axis(4) |

| Y1,Y2,Y3,Y4 | |

10. | Y1,Y2,Y3,Y4 parallel tolerance | mm | ±0.01 | |

11. | Front feeding stroke | mm | 2000 | |

12. | Rear feeding stroke | mm | 2000 | |

13. | Daylight | mm | 950 | |

14. | Main motor |

| kw | 45×2 |

CNC axis description:

Y1, Y2 axis—controls the CNC axes of the cylinders on both sides. The X-axis controls the back and forth of the back gauge, the R-axis controls the back gauge up and down, and the V-axis table is CNC crowning.