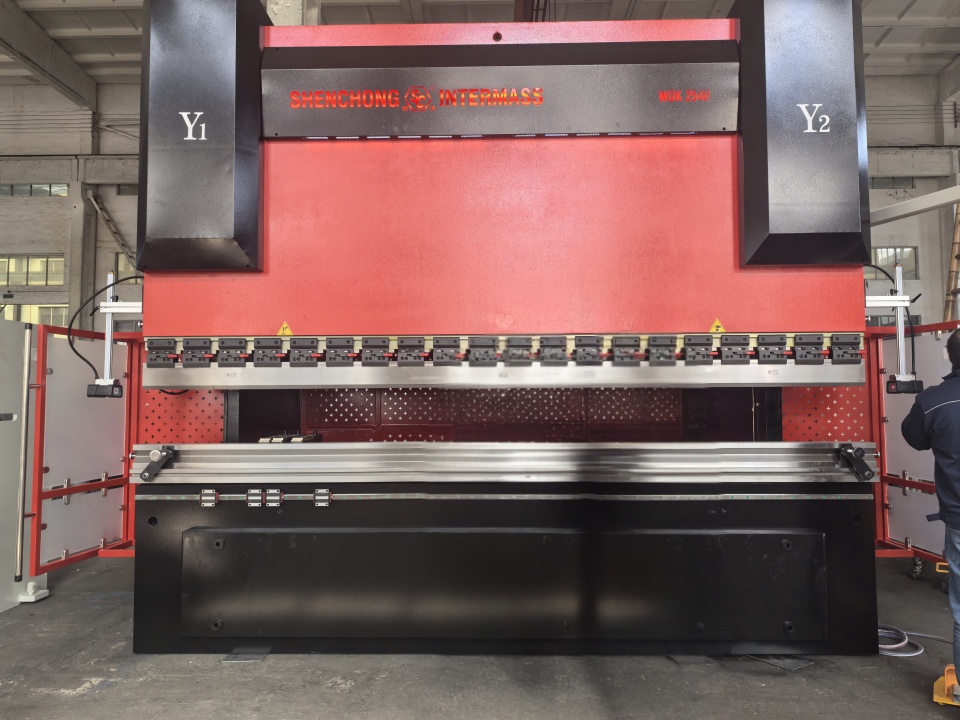

SC SHENCHONG ships one set of WDK 250 Tons 4000MM hybrid servo press brake to Egypt.

Because of the hot weather, clients in Egypt always prefer to choose our WDK series hybrid servo press brake. This series has the advantage that the oil temperature of the machine will not increase during the machine running time so that ensure the stable running of the machine.

Machine Details - Hybrid Servo Press Brake To Egypt

TYPE | WDK-250/4000(ESA S860) | ||

SR.NO. | ITEM | UNIT | SPECIFICATION |

1 | Nominal Pressure | kN | 2500 |

2 | Length of Table | mm | 4000 |

3 | Distance Between housings | mm | 3200 |

4 | Throat Depth | mm | 400 |

5 | Stroke | mm | 400 |

6 | Approach speed | mm/s | 200 |

7 | Return speed | mm/s | 200 |

8 | Working speed | mm/s | 10-15 |

9 | Axis (6+1) | Y1, Y2, X, R, +V | |

10 | Y1, Y2 parallel tolerance | mm | ±0.01 |

11 | X-axis arbitrary positioning precision | mm | ±0.025 |

12 | X-axis repeat positioning precision | mm | ±0.015 |

13 | X-axis speed | mm/s | 0-500 |

14 | X-axis positioning spacing | mm | 5-1000 |

15 | R-axis repeat positioning precision | mm | ±0.02 |

16 | R-axis speed | mm/s | 0-500 |

17 | R-axis positioning spacing | mm | 200 |

18 | Z1,Z2-axis repeat positioning precision | mm | ±0.05 |

19 | Z1,Z2-axis speed | mm/s | 0-500 |

20 | Z1,Z2-axis moving spacing | mm | 2000 |

21 | Open Height | mm | 490 |

22 | X axis servo motor | kw | 1 |

23 | R axis servo motor | kw | 1 |

24 | Main motor | kw | 8×2 |

25 | Oil tank capacity | L | 80*2 |

26 | Overall Dimensions (L*W*H) | mm | 4540x1980x3260 |

27 | Weight | T | 16.5 |

SR.NO. | ITEM | CONFIGURATION |

1 | Control system | ESA S860 (ITALY) |

2 | Hydraulic control system | REXROTH (Germany) |

3 | Ferrule | EMB (Germany) |

4 | High-pressure gear pump | ECKERLE (Germany) |

5 | Magnetic railing ruler | ELGO (Germany) |

6 | Seal ring | SKF (Sweden) |

7 | Top punch and bottom die | SHENCHONG |

8 | Back gauge system | SHENCHONG |

9 | Oil cylinder | SHENCHONG |

10 | Heavy load rolling guide | SHANGHAI |

11 | Primary motor | STARS Servo Motor |

12 | Single/bipolar air switch | Schneider |

13 | AC contactor, thermal relay | Schneider |

14 | Circuit breaker, button | Schneider |

15 | Miniature relay | Schneider |

16 | Linear guide, ball screw | SHAC (Taiwan) |

17 | Back gauge servo motor | DETAL (Taiwan) |

18 | Safety protection (Side and Back Guard) | SHENCHONG |

To meet customers’ bending requests, SHENCHONG announce WDK Serie Hybrid Servo CNC Press Brake, which provides more advantages on bending speed, energy saving and working environment.

WDK Serie press brake is equipped with a touch-screen graphic programing CNC controller and is available in 6 axes in total with 4 axes back gauge. WDK Serie is intended and designed for customers looking for better operation experience and Eco production targets.

Features Of Double Servo Pump Control System

(1) The use of servo motor makes the system low energy consumption in the working gap. The energy-saving effect is excellent. Compared with the model, the energy-saving rate is up to 70%, and the noise is even lower. When the machine is running at high speed, the noise value does not exceed 60 decibels.

(2). The distribution of oil is basically on-demand distribution without throttling loss. It can achieve real energy saving.

(3) The low temperature rises, when the ambient temperature is 38°C, the continuous working oil temperature does not exceed 50°C, which reduces the risk of oil leakage, has higher stability, and improves the service life of the hydraulic system and cylinder.

(4) Using a bidirectional gear pump, the machine tool cylinder is determined by the forward and reverse rotation of the gear pump, which reduces the dependence on the quality and stability of the hydraulic valve group. The quality of the machine tool is more stable, and it is most suitable for robots to bend.

(5) The position accuracy of the slider or the accuracy of the parts is higher than that of the proportional valve control system machine tool. After actual testing, the repeatable positioning accuracy of the slider is ±0.01mm, and the highest accuracy is ±0.005mm.

(6) The economy is better; the consumption of energy is reduced by 70% compared with the model, which greatly saves power consumption and hydraulic oil consumption.

(7) The work efficiency is higher, and the efficiency of the electro-hydraulic synchronous CNC bending machine is increased by up to 30% compared with the same period of the previous year.