Table of Contents

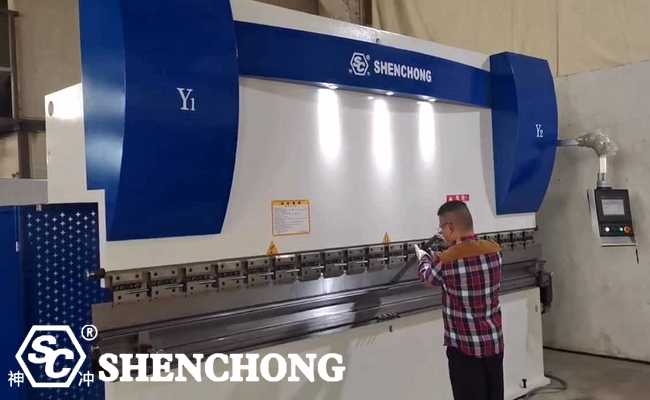

This is a 200ton 4000mm CNC press brake to Qatar. Wuxi Shenchong machines are sold to the Middle East all year round, such as Saudi Arabia, Oman, Jordan and Yemen. We have rich experience in installation and after-sales service in Middle Eastern countries.

Qatar 200ton 4000mm CNC hydraulic press brake machine is a high-precision equipment for bending metal sheets. It is widely used in machinery manufacturing, automobiles, aerospace, construction, metal processing and other fields. This equipment provides a strong bending force through the hydraulic drive system, and cooperates with the CNC system for precise control to achieve efficient and high-precision bending of metal sheets.

1. Basic parameters of CNC press brake to Qatar

Bending force: 200 tons

The maximum bending force of this bending machine is 200 tons, which can cope with the bending processing of thicker metal plates (such as carbon steel, stainless steel, aluminum alloy, etc.).

Maximum bending length: 4 meters

The equipment can handle metal plates with a maximum length of 4 meters, suitable for various medium and large-sized metal plate processing.

Number of axes: 4+1 axis

4-axis control: including Y1 (upper die lifting), Y2 (lower die lifting), X (plate lateral positioning) and R (upper die angle adjustment).

+1 axis: usually refers to an additional axis, which may be the retreat/advance of the plate or used to increase processing flexibility (such as plate correction, automatic compensation and other functions).

CNC system: ESA S630

ESA S630 is a high-precision, intelligent CNC system, widely used in modern hydraulic bending machines, which can accurately control the movement of each axis, and perform fine angle adjustment, real-time monitoring and fault diagnosis.

This Qatar 200ton 4000mm 4 + 1 axis ESA S630 CNC press brake is a electro-hydraulic bending machine with advanced technology, combining a powerful hydraulic drive system, precise CNC control and intelligent operation platform. Widely used in high-precision bending processing of metal sheets.

This bending machine adopts the Italian ESA S630 CNC system, providing efficient, high-precision and high-flexibility bending solutions. The following is a detailed introduction to the working principle and components of the equipment.

2. Working Principle

Hydraulic drive:

The 200ton CNC hydraulic press brake provides high-pressure liquid through the hydraulic system to drive the hydraulic cylinder to press the upper and lower molds against the plate to achieve bending processing. The hydraulic system provides a strong bending force to ensure efficient bending of thicker plates.

ESA S630 CNC controller:

The relative movement of the upper and lower molds of the bending machine is controlled by programming, including the up and down lifting, position adjustment, speed control, etc. of the mold to ensure processing accuracy and consistency. Through the CNC system, the operator can easily set various parameters of the workpiece (such as bending angle, length, etc.), which greatly improves processing efficiency and accuracy.

4+1 axis control:

– Y1/Y2 axis: Control the vertical movement of the upper and lower molds respectively to ensure that the upper mold accurately presses down the metal sheet.

– X axis: Control the advance and retreat of the plate in the horizontal direction to ensure the accuracy of the plate position.

– R axis: Used to adjust the angle of the upper mold, and the angle can be fine-tuned according to processing requirements to achieve the best bending effect.

– +1 axis: The additional axis is usually an automated retract axis or a precision adjustment axis to help maintain the stability and accuracy of the sheet during the bending process.

3. Main components

1) Hydraulic system

The hydraulic system is the power source of the 200ton 4meter CNC hydraulic press brake machine. It includes hydraulic pumps, hydraulic cylinders, valve groups, oil tanks and other components. The hydraulic cylinder drives the mold up and down through the pressure of the oil to achieve the bending of the metal sheet.

2) ESA 630 CNC system

The upper and lower positions, bending angles, speeds, etc. of the mold are controlled through programming. The accuracy of the ESA CNC system directly determines the accuracy and efficiency of the bending.

3) Main frame

It is welded or cast from high-strength steel plates to ensure that the bending machine remains stable during heavy load operations and reduce deformation and vibration.

4) Upper and lower dies

The upper mold and lower dies are the key parts that directly contact the metal sheet and apply bending force to it. The choice of mold is usually customized according to the material, thickness and required bending angle of the sheet.

5) Slider and transmission system

The slider is connected to the hydraulic system and moves up and down through the action of the hydraulic cylinder to push the upper mold to bend the metal sheet.

The transmission system ensures the precise docking of the hydraulic slide and the die to achieve the desired bending effect.

6) Workbench and support system

The workbench is usually equipped with a support device to support the metal sheet. When bending longer or thicker sheets, the support device can ensure the stability of the sheet and prevent it from sagging or deformation.

4. Main features

1) High precision

The CNC system provides precise motion control and can achieve high-precision bending. The bending angle, length and bending sequence can be accurately set through the program to ensure the consistency and repeatability of the workpiece.

2) High stability

The bending machine adopts a high-rigidity frame design to ensure that the machine body will not deform or move when working under heavy loads, thus ensuring processing accuracy.

3) High efficiency

Through automated programming and operation, the bending machine can complete the bending of various metal sheets of different specifications and shapes in a short time, which is suitable for mass production.

4) Wide range of applications

The bending machine is suitable for processing a variety of metal materials, such as carbon steel, stainless steel, aluminum alloy, copper, etc., and can process sheets of different thicknesses and lengths.

5. Application fields

The 200ton 4000mm 4+1-axis CNC press brake is widely used in many industries, especially for mass production of high-precision and complex shapes, mainly including:

– Automotive industry: production of metal parts such as car bodies, chassis, doors, etc.

– Building and steel structure: used for processing building steel structures, steel frames, doors and windows and other metal parts.

– Aerospace: production of complex metal parts such as aircraft parts and missile shells.

– Machinery manufacturing: processing metal parts such as mechanical equipment shells and brackets.

– Energy and power: used for bending metal structural parts of power equipment and large energy equipment.

This 200ton 4000mm CNC press brake to Qatar is a highly efficient and high-precision sheet metal bending equipment. Through the precise control of hydraulic drive and CNC system, it can achieve high-precision bending processing of thicker metal sheets.

Its powerful bending ability, intelligent control and high stability make it widely used in many industries such as automobiles, construction, and machinery manufacturing, especially suitable for large-scale, high-precision sheet metal processing. Welcome to inquire!