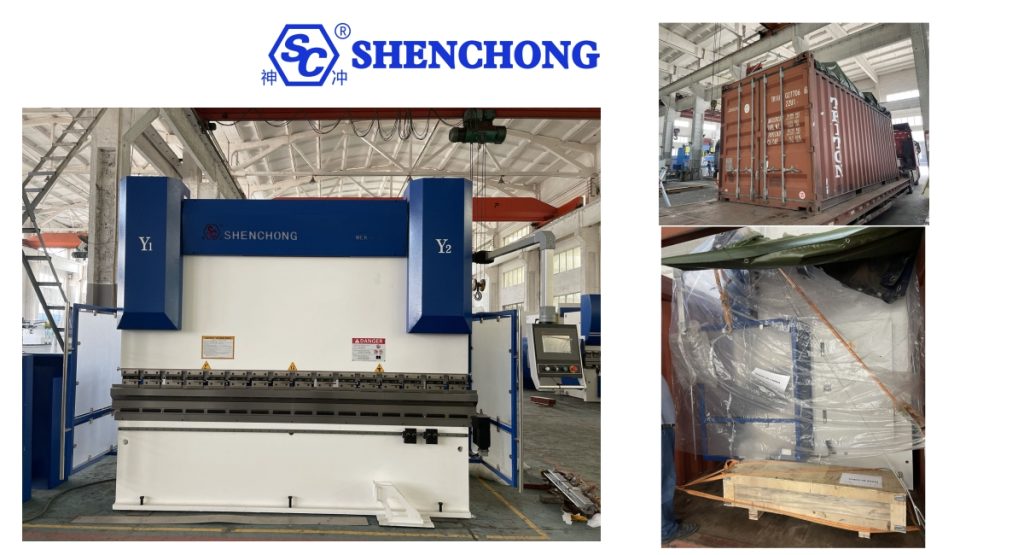

SC SHENCHONG ships one set of WDK 200 Tons 3200MM hybrid servo press brake to Saudi Arabia.

Because of the hot weather, clients in Saudi Arabia always prefer to choose our WDK series hybrid servo press brake. This series has the advantage that the oil temperature of the machine will not increase during the machine running time so that ensure the stable running of the machine.

Machine Details - Hybrid Servo Press Brake To Saudi Arabia

TYPE | WDK-200/3200(ESA S640) | ||

SR.NO. | ITEM | UNIT | SPECIFICATION |

1 | Nominal Pressure | kN | 2000 |

2 | Length of Table | mm | 3200 |

3 | Distance Between housings | mm | 2660 |

4 | Throat Depth | mm | 400 |

5 | Stroke | mm | 200 |

6 | Approach speed | mm/s | 180 |

7 | Return speed | mm/s | 180 |

8 | Working speed | mm/s | 10 |

9 | Axis (6+1) |

| Y1, Y2, X, R, Z1, Z2+V |

10 | Y1, Y2 parallel tolerance | mm | ±0.01 |

11 | X-axis arbitrary positioning precision | mm | ±0.025 |

12 | X-axis repeat positioning precision | mm | ±0.015 |

13 | X-axis speed | mm/s | 0-500 |

14 | X-axis positioning spacing | mm | 5-1000 |

15 | R-axis repeat positioning precision | mm | ±0.02 |

16 | R-axis speed | mm/s | 0-500 |

17 | R-axis positioning spacing | mm | 200 |

18 | Z1,Z2-axis repeat positioning precision | mm | ±0.05 |

19 | Z1,Z2-axis speed | mm/s | 0-500 |

20 | Z1,Z2-axis moving spacing | mm | 2000 |

21 | Open Height | mm | 470 |

22 | X axis servo motor | kw | 0.75 |

23 | R, (Z1,Z2)axis servo motor | kw | 1, (0.4×2) |

24 | Main motor | kw | 8×2 |

25 | Oil tank capacity | L | 80*2 |

26 | Overall Dimensions (L*W*H) | mm | 3760x1880x2670 |

27 | Weight | T | 10.7 |

SR.NO. | ITEM | CONFIGURATION |

1 | Control system | ESA s640 (Italy) |

2 | Hydraulic control system | REXROTH (Germany) |

3 | Ferrule | EMB (Germany) |

4 | High-pressure gear pump | ECKERLE (Germany) |

5 | Magnetic railing ruler | ELGO (Germany) |

6 | Seal ring | SKF (Sweden) |

7 | Top punch and bottom die | SHENCHONG |

8 | Back gauge system | SHENCHONG |

9 | Oil cylinder | SHENCHONG |

10 | Heavy load rolling guide | SHANGHAI |

11 | Primary motor | STARS Servo Motor |

12 | Single/bipolar air switch | Schneider |

13 | AC contactor, thermal relay | Schneider |

14 | Circuit breaker, button | Schneider |

15 | Miniature relay | Schneider |

16 | Linear guide, ball screw | SHAC (Taiwan) |

17 | Back gauge servo motor | DETAL (Taiwan) |

18 | Safety protection (Side and Back Guard) | SHENCHONG |

To meet customers’ bending requests, SHENCHONG announce WDK Serie Hybrid Servo CNC Press Brake, which provides more advantages on bending speed, energy saving and working environment.

WDK Serie press brake is equipped with a touch-screen graphic programing CNC controller and is available in 6 axes in total with 4 axes back gauge. WDK Serie is intended and designed for customers looking for better operation experience and Eco production targets.

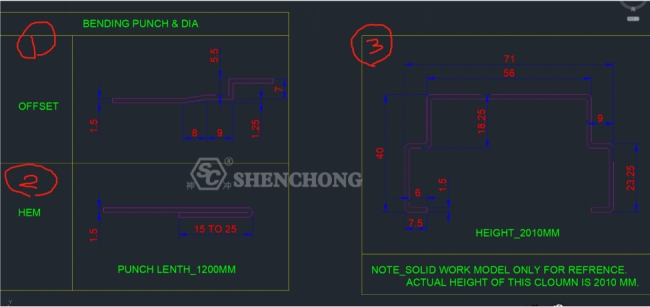

Client’s Workpieces Bending Proposal

This client from Saudi Arabia has special workpieces to bend, which need to be bent on special designed press brake tooling.

Machine Tools - Upper Punch and Lower Dies

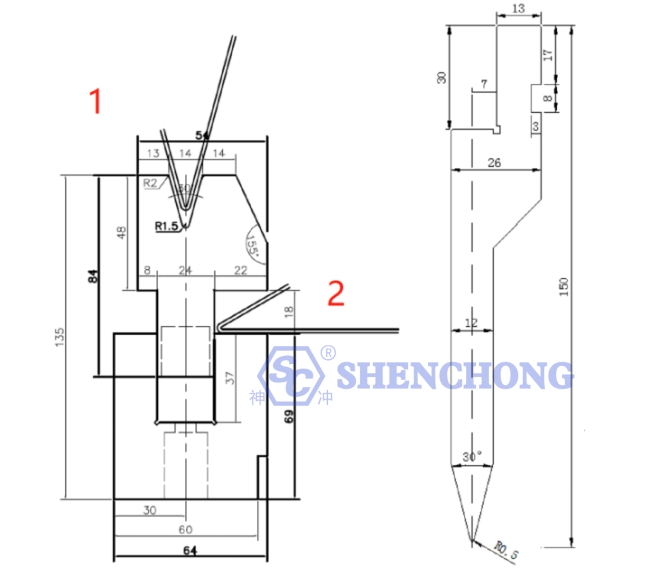

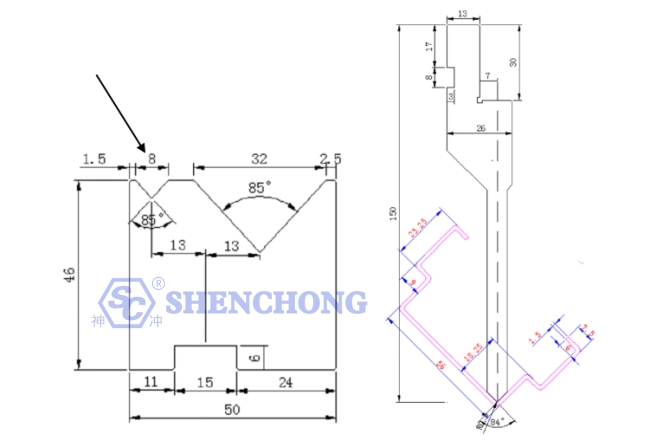

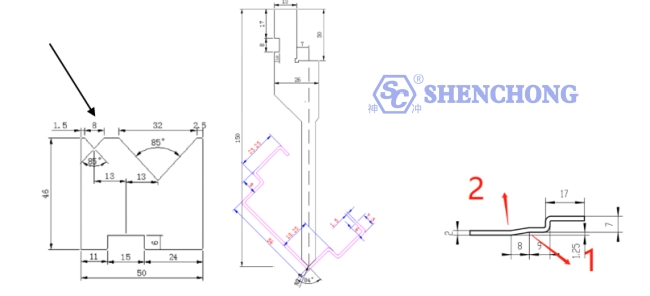

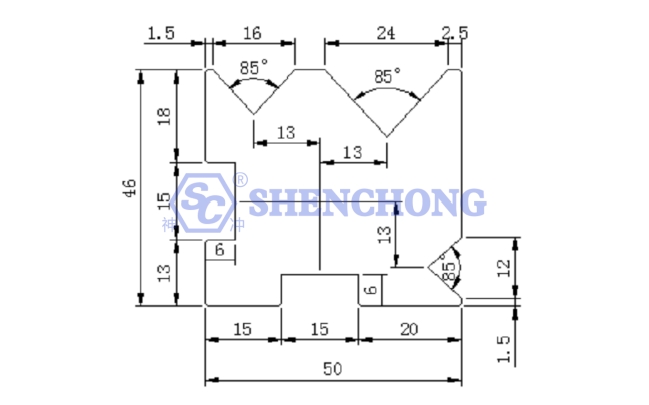

a) To bend your workpiece no.2: choose below upper punch and lower die (1200mm, 42CrMo), below press brake tools can bend thickness 1.2mm – 2mm. Step 1: use V14 groove to bend the sheet as below “1”, then hem the angle as below “2”.

b) To bend your workpiece no.1 and no.3 (thickness from 1.2mm-1.5mm), choose below upper punch and lower die (2500mm, 42CrMo), use V8 groove.

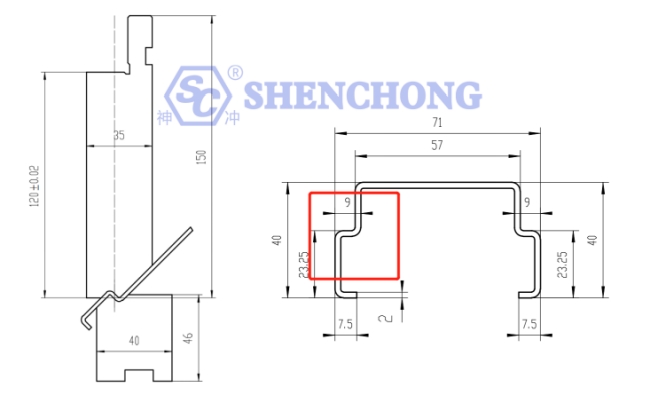

c) To bend your workpiece no.3 (thickness 2mm), step 1. Choose below forming tool (2200mm, 55SiCr) to bend the part as I show below:

Step 2: change press brake tool b), use V8 groove to bend other angles.

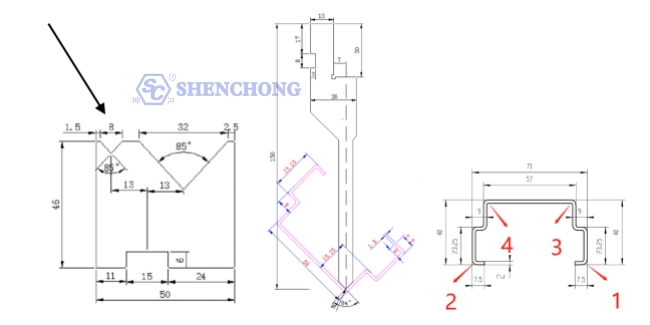

d) To bend your workpiece no.1 with 2mm, step 1 choose below forming tool (1200mm, 55SiCr) to bend the part as I show:

Step 2:

Change b) press brake tool, to bend other parts:

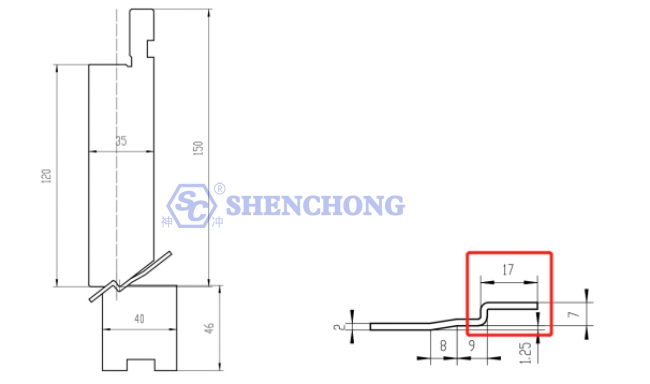

e) To bend normal shape 1.5mm,2mm,3mmthickness sheet, you can use below lower die and upper punch shown in b) (3200mm, 42CrMo).

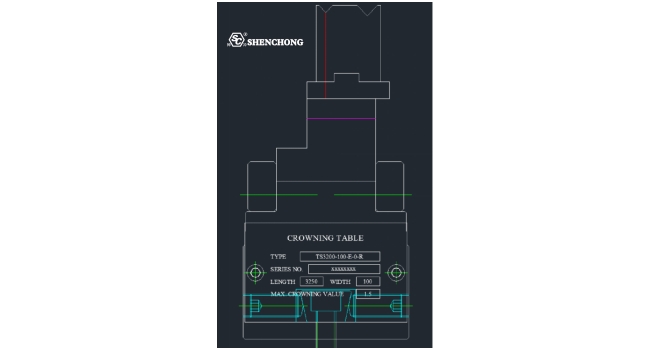

f) All above lower dies need to set on the below lower die support, see as below schematic diagram.