SC WEK 200 Ton 4000mm CNC Press Brake Machine 3+1 Axis With ESA S630 Controller

SC® 3 Axis 200 ton 4000mm CNC Press Brake for sale with ESA S630 CNC for sheet metal plate bending machine is our most popular model by volume and a true workhorse. The CNC hydraulic press brake constructed of high quality parts and offering serious reliability, Y1 & Y2 technology with high approach, bending and return speeds.

To meet customers’ bending requests, SHENCHONG announce WEK Serie Electro-Hydraulic CNC Press Brake, which has become the most popular CNC Press Brake type in the global market.

WEK Serie press brake is equipped with a touch-screen graphic programing CNC controller and is available in 3 axes in total with 2 axes back gauge. WEK Serie is intended and designed for customers looking for the basics and ease of use.

SC Machinery 200T X 4000MM CNC Press Brake Main Features

- The whole steel plate is welded, the stress is eliminated by the vibration after tempering, the stability is good. The machine sandblasted and sprayed with anti-rust paint; The machine frame is processed by imported CNC three-dimensional processing center, which ensures the parallelism and verticality of each installation.

- Adopt electro-hydraulic servo control system, the hydraulic system has the overload and overflow safety protection, the oil level is highly clear and intuitionistic shown, the sealing parts in the cylinder are imported, with pretty quality and good performance.

- Continuous work under the rated load, the hydraulic system ensures that no leakage and the processing is continuous and stable, with high precision.

- It is suitable for producing multi-channel bending and high-precision work piece.

- The back gauge X axis adopts ball screw, linear guide transmission, digital AC servo motor drive, and the back gauge has the back control function.

Standard Configuration

- movable sliding front support arms.

- ESA S630 graphical controller with PC-Profile-T2D software.

- Easy clamping system.

- 3 +1 axis CNC:

- Y1, Y2 precision ram positioning.

- X, R precision servo-driven back gauge.

- Manually adjustable Z1, Z2-axis.

- CNC motorized wave crowning.

- 2 back gauge fingers

- Top and bottom tools are surface hardened by special treatment.

- Foot pedal is produced according to CE standards and suitable for single and multiple bends.

- 2 photocells are placed facing each other for rear guards.

- Electrical cabinet with ABB switch power off device

- Electrical panel with cooling system designed to meet CE standards & composed of automation and electrical equipment with Schneider

- Cooling device to prevent overheating of oil tank

Machine Details

Safety Protection

Shenchong CNC press brake standard safety protection includes:

Side protection and back door protection

Electrical cabinet with ABB switch power off device

Fan in the electrical box prevent overheating

Cooling device to prevent overheating of oil tank

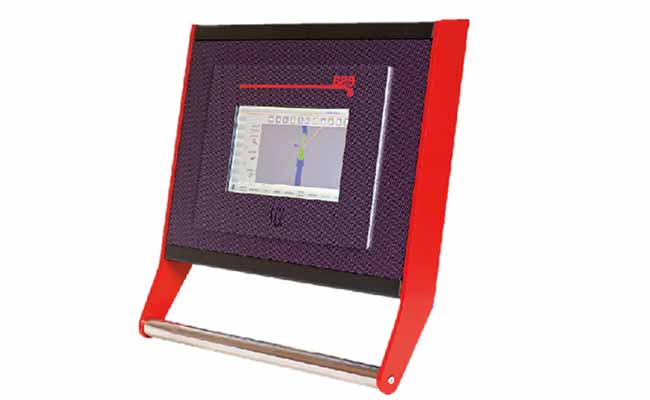

ESA S630 Controller

- Graphic color 10” touch screen display (1024 x 600 pixels resolution).

- 128 silicon disk.

- Interactive 2d graphic editor for work-pieces and tools data entry.

- 2D graphic display of machine frame, work-piece and tools.

- Manual 2D graphic identification of the best bending sequence(option)

- 4 fast counting circuits for line drive 0-5Vdc differential encoders or npn/push pull. The encoders are powered at 5Vdc (max 200mA per channel).

Technical Parameter

TYPE | WEK-200/4000(ESA S630) | ||

SR.NO. | ITEM | UNIT | SPECIFICATION |

1 | Nominal Pressure | kN | 2000 |

2 | Length of Table | mm | 4000 |

3 | Distance Between housings | mm | 3200 |

4 | Throat Depth | mm | 400 |

5 | Stroke | mm | 200 |

6 | Approach speed | mm/s | 180 |

7 | Return speed | mm/s | 100 |

8 | Working speed | mm/s | 8 |

9 | Axis (3+1) |

| Y1, Y2, X +V |

10 | Y1, Y2 parallel tolerance | mm | ±0.01 |

11 | X-axis arbitrary positioning precision | mm | ±0.025 |

12 | X-axis repeat positioning precision | mm | ±0.02 |

13 | X-axis speed | mm/s | 0-500 |

14 | X-axis positioning spacing | mm | 5-1000 |

15 | Open Height | mm | 470 |

16 | Main motor | kw | 15 |

17 | Overall Dimensions (L*W*H) | mm | 4540*1880*2770 |

18 | Weight | T | 12.2 |

Frequently Asked Questions

The price of a 200tons 4000mm cnc press brake can vary greatly depending on the machine series types, number of axes, configuration, and specification of the machine. Additionally, prices may also be affected by the country of manufacture, shipping and installation costs, and any additional taxes and charges. Under normal circumstances, the price of a WEK 200 ton 4000mm hydraulic CNC press brake for sale with basic functions ranges from $32,000 to $42,000. Plus, higher-end machines with advanced performance and larger cut sizes can cost more, from $41,000 to $49,000

It is important to note that the initial cost of a press brake is only one factor to consider when estimating its value. Other factors to consider include the machine’s reliability, ease of use, and output quality, as well as ongoing maintenance and operating costs. While the upfront cost of a CNC press brake machine may seem high, it can provide significant cost savings and increased bending efficiency in the long run, especially for high-volume and precision cutting applications.

If you are considering buying a 200 Ton 4000MM CNC press brake machine, you can contact us. SC Machinery, as a professional cnc press brake manufacturer, can not only provide you with a competitive price but also provide you with perfect customer support and warranty.

The maximum thickness that a 200 ton 4000mm CNC press brake machine can bend depends on the type of material being bend and the sheet plate length. In general, a 200T 4000mm press brake machine can cut the following materials at most:

Mild Steel: It can bend mild steel plates with thicknesses 6mm and the plate length 4000mm.

Stainless Steel: 200 tons 4000mm press brake can bend stainless steel plate thickness 4mm with length 4000mm.

Aluminum: It can bend aluminum plates with thicknesses 16mm and the plate length 4000mm.

It is important to note that these thicknesses are general guidelines and may vary by specific machine and application.

Request Informations

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.