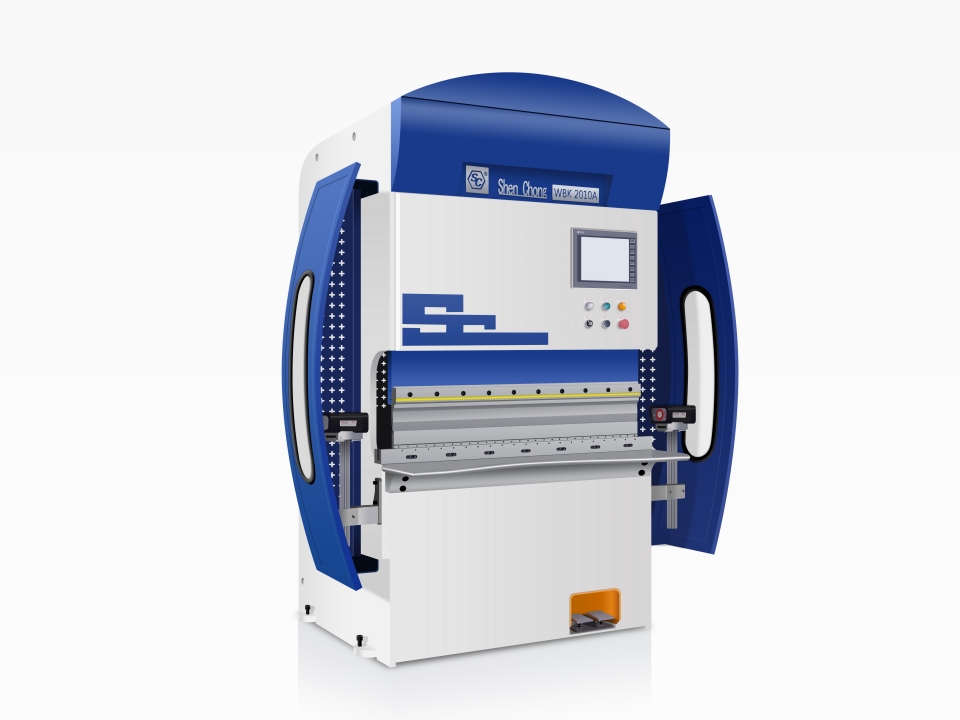

Press brake is a machine used to bend cold metal sheets into various geometric cross-sectional shapes using the provided molds (universal or specialized). The CNC press brake machine generally adopts the special CNC control system to automatically realize the ram position running depth control, the ram left and right tilt adjustment, backgauge front and rear adjustment, backgauge finger left and right adjustment, pressure tonnage adjustment, the ram approaching working speed adjustment, etc. The CNC system allows the press brake machine to conveniently perform actions such as the ram downward, jogging, continuous, pressure maintaining, return, and midway stopping, completing multiple bending at the same or different angles with one feeding.

Using CNC press brakes, operators can quickly program and continuously operate multiple bending steps.

While a CNC press brake machine is more expensive to purchase than NC press brake, it offers high precision and consistency that can save money over time. This is particularly true for high volume manufacturing operations where efficiency is key.

CNC press brake is a modern metal processing equipment controlled by computer programs, which main function is to bend metal sheets. It controls the operating system through programming software, accurately controlling the movement trajectory and speed of the machine tool oil cylinder, thereby achieving high-precision, high-efficiency, and highly automated production.

CNC controller not only give instruction to the CNC press brake machine, but also receive the feedback of the machine. It automatically analyze the data and adjust the machine action, and this is why cnc press brake has higher bending precision.

SC SHENCHONG robotic press brake is the CNC press brake connect with the bending robot to reduce the labor cost and improve the bending efficiency. We use 3 most popular bending robot brands in the world, ABB, KAWASAKI, STEP. We are professional press brake factory and we can design and install the robot press brake for clients.

WDK hybrid servo press brake is the lasted generation CNC press brake, which has the advantages of energy saving and stable operation. It can save 70%-80% electrical consumption and the oil temperature would not increase by long time working, which ensure the machine bending quality. For these advantages, hybrid servo press brake is the best press brake to connect with robot.

WEK CNC hydraulic press brake is the traditional hydraulic press brake with CNC controller, which operators can use CNC controller to adjust the ram stroke(Y1,Y2 axes), the backgauge forward and back movement (X axis), the backgauge up and down movement (R axis), backgauge finger left and right movement (Z axis), and working table compensation (V axis).

Tandem press brake is two big capacity CNC press brake connect together. Tandem press brake machines are usually operate to bend the light poles, high mast poles and other long and thick sheet plate. The two press brake machines can connect together to work synchronously or they can separately to work.

SC SHENCHONG WGK mini press brake is a type of high speed hydraulic press brake. It has the unique single cylinder structure and can reach the super fast approaching speed at 300mm/s. For this reason, SC SHENCHONG high speed mini press brake has the standard configuration – laser protection. This series of press brake is the best bending choice for box and cabinet production.

WC67K NC press brake is the torsion bar press brake with ESTUN E21 NC controller. Torsion bar press brake is the old style hydraulic press brake that adopts the torsion bar to synchronously control the ram. NC press brake is a kind of economically friendly bending machine.

SC press brake bending follower is different from the traditional sheet follower that need to use the CNC controller of the press brake. SC SHENCHONG press brake bending follower has its own independent CNC controller and can hold the sheet plate during the whole bending process. One set of press brake bending follower can connect with several press brakes.

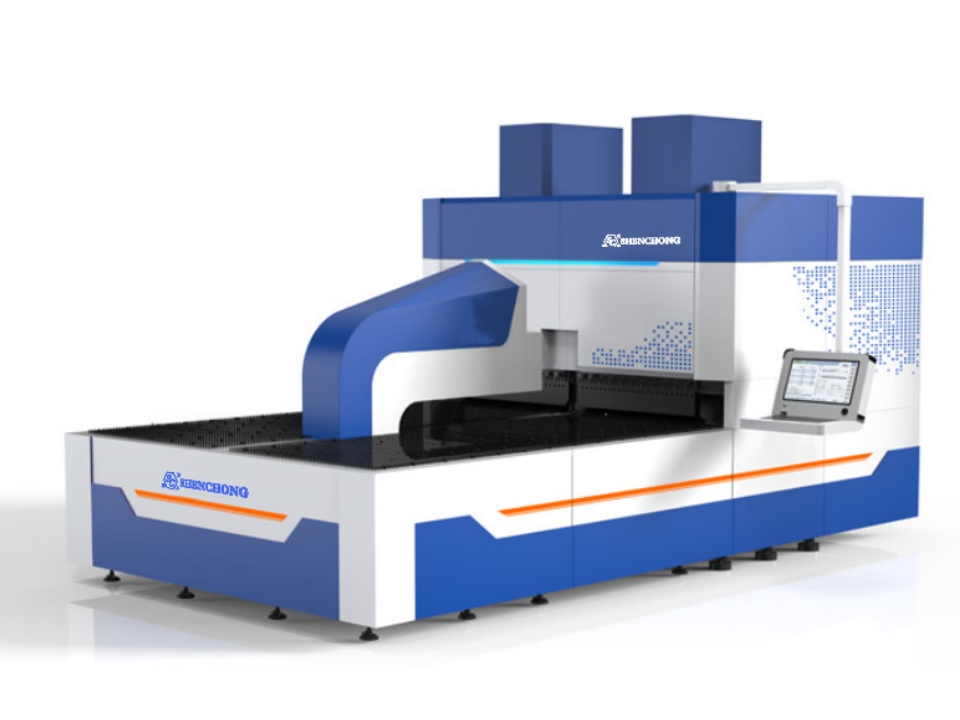

SC SHENCHONG automatic panel bending center is the most popular bending solution for thin sheet plates. Panel bender with high automation function can helps to bend the product from raw material to final workpiece one time without labor operation. Fast and high product efficiency are the key advantages of automatic panel bender.

CNC V grooving machine is the auxiliary equipment to cut the v notch before bending. By using the CNC V grooving machine, the following bending result can be more beautiful. SC SHENCHONG provides both horizontal CNC V grooving machine and vertical CNC V grooving machine for sale.

Backgauge is a critical component in press brake machine. Press brake backgauge refers to the system that automatically positions the workpiece for bending operations accurately. Press brake backgauges typically have multiple axes that can be controlled to adjust the position of the workpiece. The number of axes can vary depending on the automation and complexity of the press brake.

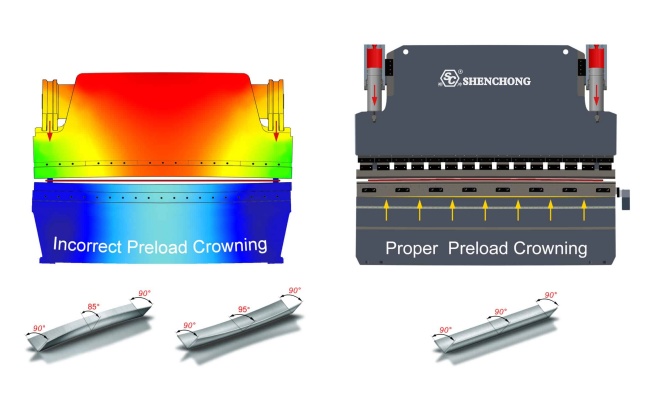

During the bending process, stress can cause some deformation of the ram and worktable. CNC crowning of the press brake can compensate for the ram deformation that greatly improve the bending accuracy. Press brake CNC crowning system refers to the process of compensating for material deflection that occurs when bending sheet metal or other flat material. Crowning is the method of adding a curve, or crown, to the top of the press brake’s upper die to counteract deflection and ensure accurate.uniform bends. When a flat material is bent, it tends to deflect or bow in the center, which can result in a wavy or uneven bend. To overcome this problem, the press brake’s upper die is designed with a curved surface, or crown, which helps to distribute the bending force evenly across the material, producing a uniform bend.

Main technical features

Below is the comparison table for the ESA S630, ESA S640, ESA S860, DELEM DA53T, DA58T, DA66T, DA69T, Cybelec Touch 12, and Touch 15 CNC controllers.

Feature/Model | ESA S630 | ESA S640 | ESA S860 | DELEM DA53T | DELEM DA58T | DELEM DA66T | Cybelec Touch 12 | Cybelec Touch 15 |

Display | 7″ TFT Color Touchscreen | 15″ TFT Color Touchscreen | 19″ TFT Color Touchscreen | 10.1″ TFT Touchscreen | 15″ TFT Color Touchscreen | 17″ TFT Color Touchscreen | 12″ TFT Color Touchscreen | 15″ TFT Color Touchscreen |

Axes Control | 4-Axis Control | 4-6 Axis Control | Up to 12 Axis Control | 4-Axis Control | 8-Axis Control | Up to 12-Axis Control | 4-6 Axis Control | Up to 18-Axis Control |

Programming | 2D graphical programming | 2D graphical programming | 3D graphical programming | 2D graphical programming | 2D graphical programming | 3D graphical programming | 2D graphical programming | 3D graphical programming |

Offline Programming | Optional | Yes | Yes | No | Yes | Yes | Yes | Yes |

Bending Simulation | Yes | Yes | Yes (Advanced 3D) | No | Yes | Yes | Yes | Yes |

USB Connectivity | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

Ethernet | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

Tool Library | Basic | Expanded | Advanced | Expanded | Expanded | Advanced | Expanded | Advanced |

Material Library | No | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

Backgauge Control | Basic | Advanced | Advanced | Advanced | Advanced | Advanced | Advanced | Advanced |

3D Visualisation | No | No | Yes | No | Yes | Yes | Yes | Yes |

Price Category | Lower Range | Mid Range | High Range | Mid Range | Mid-High Range | High Range | Mid Range | High Range |

Axis Upgrades | No | Yes | Yes | No | Yes | Yes | Yes | Yes |

CNC press brake machine adopts digital calculation and cnc control technology, which can accurately control the bending angle, bending force, displacement, etc. It can achieve a very high level of processing accuracy. It can effectively improve production efficiency during mass production and high-precision processing, while also ensuring product quality and stability.

Compared with traditional manual bending machines or NC press brake, CNC press brake machines have the advantage of high efficiency. Automated operations save labor costs while also enabling quick completion of product processing.

The automation operation of CNC press brake enables them to save manual operations, which reduces labor costs. At the same time, due to the high precision and other advantages of CNC bending machines, their product quality is high, which can effectively avoid wasting time, costs, and other issues due to differences in quality. These factors can effectively reduce production costs.

The flexibility of CNC press brake machines much better than NC bending machines. Firstly, adjustments and reprogramming can be made for different product types quickly; secondly, in different production situations, intermediate operations can be carried out according to requirements; furthermore, CNC press brake machines can process different types of parts at once, which can shorten the processing cycle, improve efficiency, and provide high-quality products, eliminating the risk and low efficiency caused by personnel misoperation.

CNC program storage and call function of the CNC press brake is very powerful, and it can process various steps. CNC press brake machine can adjust and optimize processing requirements from different processes to produce more precise products.

The CNC bending machine is easy to operate and maintain, and you only need to be familiar with relevant operations and equipment maintenance to quickly get started. After training, operators can independently complete the operation of the machine, making the operation simple and easy to understand, greatly improving production efficiency.

Compared with traditional manual or NC press brake machines, CNC press brake machines have the following advantages:

High accuracy: due to being controlled through computer programs, the bending angle and size can achieve very high accuracy.

High degree of automation: automatic production can be achieved by inputting the correct program without manual intervention.

High production efficiency: compared to other methods of bending production, CNC press brake machines can quickly perform a large amount of production work.

The ram part: adopts hydraulic transmission, and the ram slider part is composed of the ram, oil cylinder, and mechanical ram adjustment structure. The left and right oil cylinders are fixed on the frame, and the piston (rod) is driven by hydraulic pressure to move the ram up and down. The whole ram running position is controlled by CNC controller.

Working table part: Press brake lower dies are assembly on the working table. To ensure the bending linear accuracy, CNC press brake has cnc table crowning system, which can be mechanical type or hydraulic type connected on the working table.

Synchronous system: Unlike traditional press brake bending machines, cnc press brake uses servo valves and hydraulic devices such as grating scale or magnetic scale to form a closed-loop circuit, thereby accurately controlling various movements of the machine.

Backgauge mechanism: CNC press brake backgauge is driven by servo motor, which drives two screw rods to move synchronously through chain operation. The CNC system controls the moving position of the backgauge.

Firstly, choose the cnc press brake model match with your workpiece bending requirements. The press brake model is depended on the plate material type, plate length and plate thickness. It is the best way to contact with us and show your workpiece drawing so that we will choose the most suitable machine model for you.

Secondarily, shorter the machine, less bending deflection. Under the same load, the deflection of the 10 feet machine is four times that of the 5 feet machine. Choose the machine with table crowning is very important.

Thirdly, bending accuracy is a factor that needs to be carefully considered, and it is precisely this factor that determines whether you need to consider a CNC press brake machine or a manual /NC press brake machine. The repetitive accuracy of the CNC press brake ram is ± 0.01mm. The repetitive accuracy of the manual/NC bending machine ram is ± 0.05mm, and under the conditions of using suitable molds, it generally produces a deviation of ± 2-3 °.

No, it is very easy for a worker to learn how to operate CNC press brake. The automation of CNC press brake has made great progress now. After setting the parameters in the CNC system, the bending machine can automatically bend the workpiece. The bending angle and size can be intuitively set on the touch screen in the CNC controller. Basic production and processing are still very easy, and training for ten to twenty minutes can be used for operation. As one of the top professional CNC press brake manufacturers, SHENCHONG provide perfect after-sales service, and we will definitely teach your workers to operate the CNC press brake machine.

CNC press brake is relatively expensive than NC press brake if customers buy small or medium size machine model from 20 Tons to 400 Tons. However, if customers buy large machine model, such as 500 tons press brake or even larger size, CNC press brake price would not be more expensive. This is because to produce large size NC press brake, it need larger torsion bar, which cause higher production cost.

Can you pls tell us your plate thickness and length? Our sales will recommend machine model for you.